A nano-silicon/silicon nitride film-type electron source and its manufacturing method

A technology of silicon nitride thin film and manufacturing method, which is applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, circuits, etc., can solve the problem of poor electron emission stability, unstable mechanical and chemical properties of porous silicon electron sources, and unfavorable Preparation of devices for long-term use, etc., to achieve good physical and chemical stability, high melting point and high density, good electron emission ability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

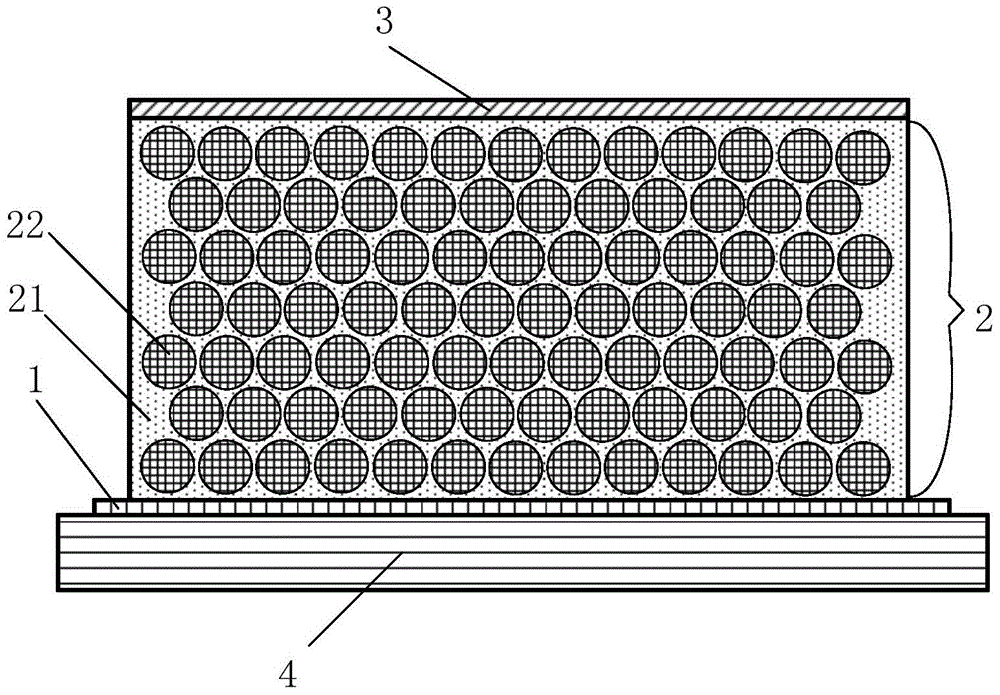

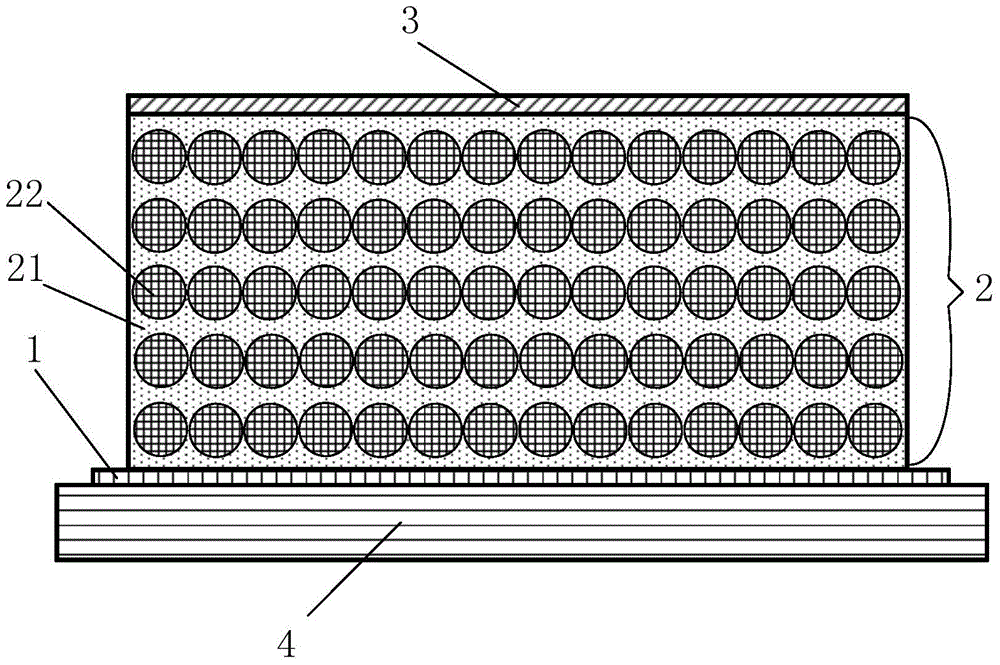

[0036] like figure 1 The preparation method of the first shown nano-silicon / silicon nitride film electron source comprises the following steps:

[0037] 1) Depositing the bottom electrode 1 on the substrate 4 by sputtering a target material of one material among tungsten, nickel, chromium, aluminum, copper, titanium or a composite target material composed of several of them, and its thickness is 40-200nm;

[0038] 2) Depositing a nano-silicon / silicon nitride layer 2 with a thickness of 100-2000nm on the bottom electrode 1, the method is:

[0039] Deposit a silicon-rich silicon nitride film on the bottom electrode 1, in which silicon exists in an amorphous form, and then in nitrogen or a mixed gas composed of nitrogen and hydrogen with a volume ratio of (50:1)-(10:1) Perform high-temperature annealing on the silicon-rich silicon nitride film at 500-1100°C, and the high-temperature annealing time is 30-120 minutes, so that the silicon-rich silicon nitride film (SiN x , x<4 / 3) ...

Embodiment 1

[0062] see figure 1 , the manufacturing process of the nano-silicon / silicon nitride thin film electron source includes the following steps:

[0063] 1) Depositing the bottom electrode 1 on the substrate 4 by using a sputtering tungsten target with a thickness of 200 nm;

[0064] 2) Introduce argon and nitrogen into the coating chamber, control the partial pressure ratio of argon and nitrogen to 3:1, and make the total pressure in the coating chamber 0.1Pa, the temperature of the substrate 4 is controlled at 550°C, and the silicon target Deposit a silicon-rich silicon nitride film with a thickness of 500nm on the bottom electrode 1 as the sputtering source; then, anneal at 900°C for 120 minutes in a mixture of nitrogen and hydrogen with a volume ratio of 25:1 to transform the amorphous silicon into Nanocrystalline silicon 22 to form a silicon nitride 21 film inlaid with nanocrystalline silicon 22, this film is nano-silicon / silicon nitride layer 2, the particle size of silicon ...

Embodiment 2

[0067] see figure 1 , the manufacturing process of the nano-silicon / silicon nitride thin film electron source includes the following steps:

[0068] 1) Depositing the bottom electrode 1 on the substrate 4 by using a sputtering nickel target, the thickness of which is 100 nm;

[0069] 2) Introduce argon gas into the coating chamber, control the air pressure in the coating chamber to 0.3Pa, control the temperature of the substrate 4 at 500°C, and deposit a thickness of 200nm silicon-rich silicon nitride film; then, anneal for 90 minutes at 1000°C in a mixture of nitrogen and hydrogen with a volume ratio of 30:1 to convert amorphous silicon into nanocrystalline silicon 22 to form nanocrystalline silicon embedded 22 silicon nitride 21 film, this film is nano-silicon / silicon nitride layer 2, the particle size of silicon grain 22 is 3-6nm, and the adjacent nano-crystals in the silicon nitride 21 film inlaid with nano-crystal silicon 22 The silicon nitride 21 between the silicon 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com