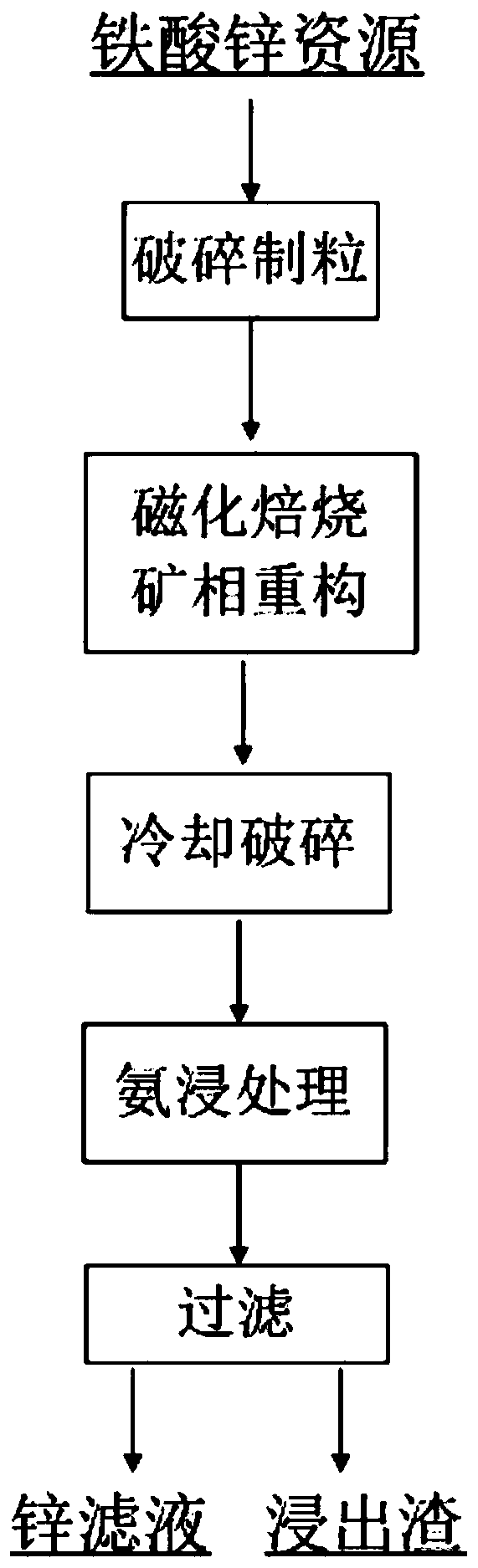

A method for recovering zinc from zinc ferrite resources using magnetization roasting-ammonia leaching

A technology of magnetization roasting and zinc ferrite, which is applied in the field of zinc recovery, can solve the problems that there is no clean and efficient utilization method for recovery and utilization of zinc, that it cannot be effectively recycled, and that the utilization rate is less than 5%. Fast speed and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, granulate into small balls of 3-20mm, and carry out magnetization roasting in the rotary kiln to reconstruct the ore phase. The magnetization roasting system is: P(CO) / P( CO+N 2 ) = 25%, the roasting temperature is 750°C, the roasting time is 45min, cooled naturally, crushed to -3mm, and subjected to ammonia leaching treatment. , the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 6mol / L, and the zinc leaching rate is 85.67% after the leaching solution is filtered.

Embodiment 2

[0031] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, granulate into small balls of 3-20mm, and carry out magnetization roasting in the rotary kiln to reconstruct the ore phase. The magnetization roasting system is: P(CO) / P( CO+N 2 ) = 20%, the roasting temperature is 800°C, the roasting time is 60min, cooled naturally, crushed to -3mm, and subjected to ammonia leaching treatment. , the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 6mol / L, and the zinc leaching rate is 86.65% after the leaching solution is filtered.

Embodiment 3

[0033] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, granulate into small balls of 3-20mm, and carry out magnetization roasting in the rotary kiln to reconstruct the ore phase. The magnetization roasting system is: P(CO) / P( CO+N 2 ) = 25%, the roasting temperature is 750°C, the roasting time is 45min, cooled naturally, crushed to -3mm, and subjected to ammonia leaching treatment. , the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 7mol / L, and the zinc leaching rate is 87.81% after the leaching solution is filtered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com