Processing method of black tea rich in dietary fiber

A technology of dietary fiber and processing method, which is applied in the processing field of black tea, can solve problems such as shortage, cumbersome process steps, unsatisfactory absorption rate of active ingredients, etc., and achieve the effects of promoting the transformation of chemical components, eliminating the grassy smell, and improving the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

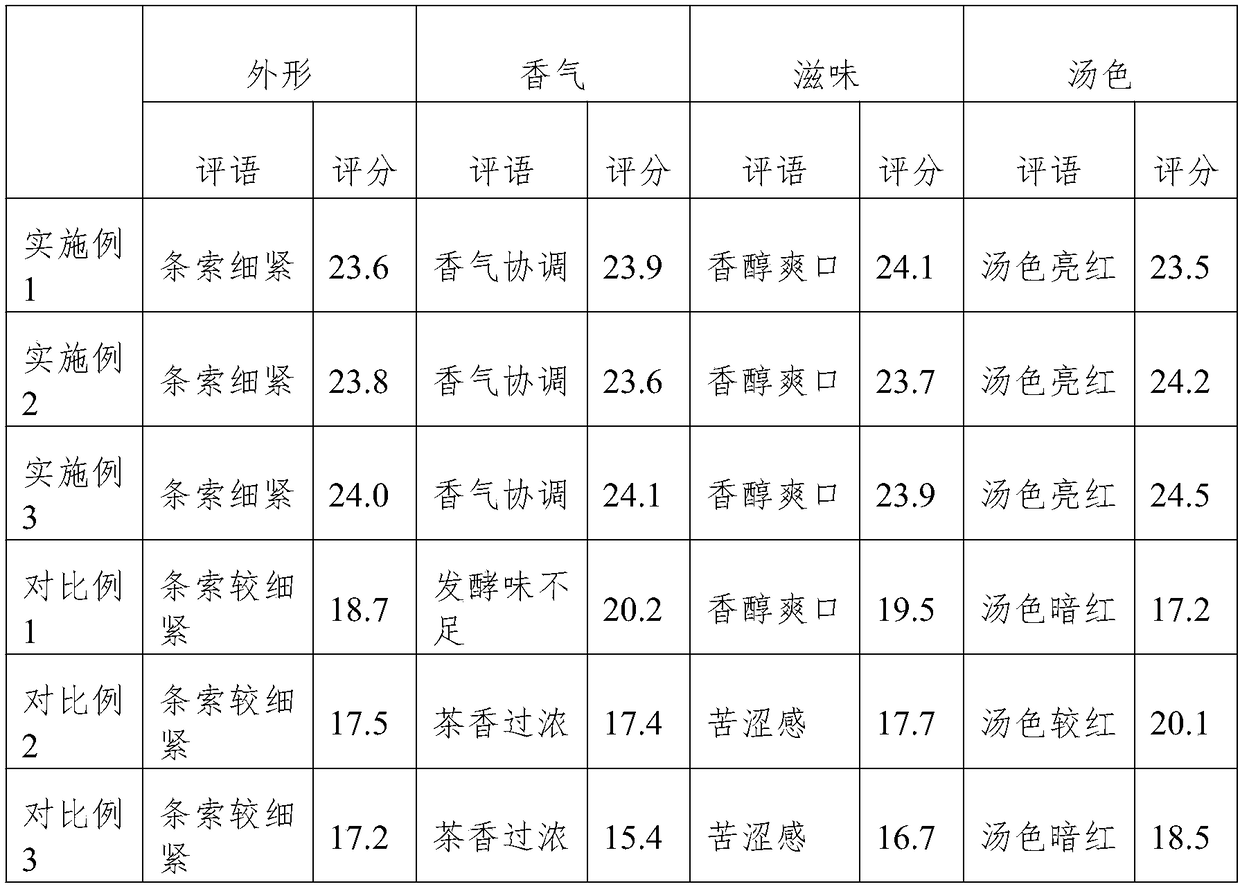

Examples

Embodiment 1

[0031] A processing method of black tea rich in dietary fiber, comprising steps as follows:

[0032] S1 fresh leaf picking: choose one bud and one leaf or one bud and two leaves as raw materials;

[0033] S2 warming and withering: Put the fresh leaves into the withering frame and spread them in an orderly manner. The thickness of the spreading is 35cm. The temperature in the withering room is controlled at 36°C. Withering at a constant temperature at 48°C until the moisture content of the tea leaves is 56%;

[0034] S3 kneading: kneading at a constant temperature in a kneading machine with a temperature of 40°C until the moisture content of the tea leaves is 47%;

[0035] S4 Freezing: Place the rolled tea leaves in a freezer at minus 10°C for 30 minutes;

[0036] S5 infiltration: Spray the dietary fiber solution on the surface of the tea leaves, the amount of the dietary fiber solution is 8% of the quality of the tea leaves;

[0037] S6 fermentation: Put the infiltrated tea...

Embodiment 2

[0043] A processing method of black tea rich in dietary fiber, comprising steps as follows:

[0044] S1 fresh leaf picking: choose one bud and one leaf or one bud and two leaves as raw materials;

[0045] S2 warming and withering: put fresh leaves into the withering frame and spread them in an orderly manner with a thickness of 30 cm. The temperature in the withering room is first controlled at 32°C, and withered at a constant temperature until the moisture content of the tea leaves is 83%, and then the temperature is raised to the temperature in the withering room. Wither at a constant temperature of 45°C until the moisture content of the tea leaves is 52%;

[0046] S3 kneading: place in a kneading machine with a temperature of 35°C and knead at a constant temperature until the moisture content of the tea leaves is 42%;

[0047] S4 Freezing: Place the rolled tea leaves in a freezer at minus 5°C for 20 minutes;

[0048] S5 infiltration: Spray the dietary fiber solution on th...

Embodiment 3

[0055] A processing method of black tea rich in dietary fiber, comprising steps as follows:

[0056] S1 fresh leaf picking: choose one bud and one leaf or one bud and two leaves as raw materials;

[0057] S2 warming and withering: put fresh leaves into the withering frame and spread them in an orderly manner. The thickness of the spreading is 32cm. The temperature in the withering room is controlled at 34°C, and the temperature is withered until the moisture content of the tea leaves is 84%. Withering at a constant temperature at 46°C until the moisture content of the tea leaves is 55%;

[0058] S3 kneading: kneading at a constant temperature in a kneading machine with a temperature of 37°C until the moisture content of the tea leaves is 45%;

[0059] S4 Freezing: Freeze the rolled tea leaves in a freezer at minus 8°C for 25 minutes;

[0060] S5 infiltration: Spray the dietary fiber solution on the surface of the tea leaves, the amount of the dietary fiber solution is 7% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com