Biological enzymolysis mushroom extract and preparation method thereof

A technology of shiitake mushroom extract and shiitake mushroom extract liquid, applied in the field of biological enzymatic hydrolysis of shiitake mushroom extract and its preparation, can solve the problems that the enzymatic hydrolysis effect needs to be strengthened and improved, and achieve the effects of improving physical and chemical properties, mild conditions, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

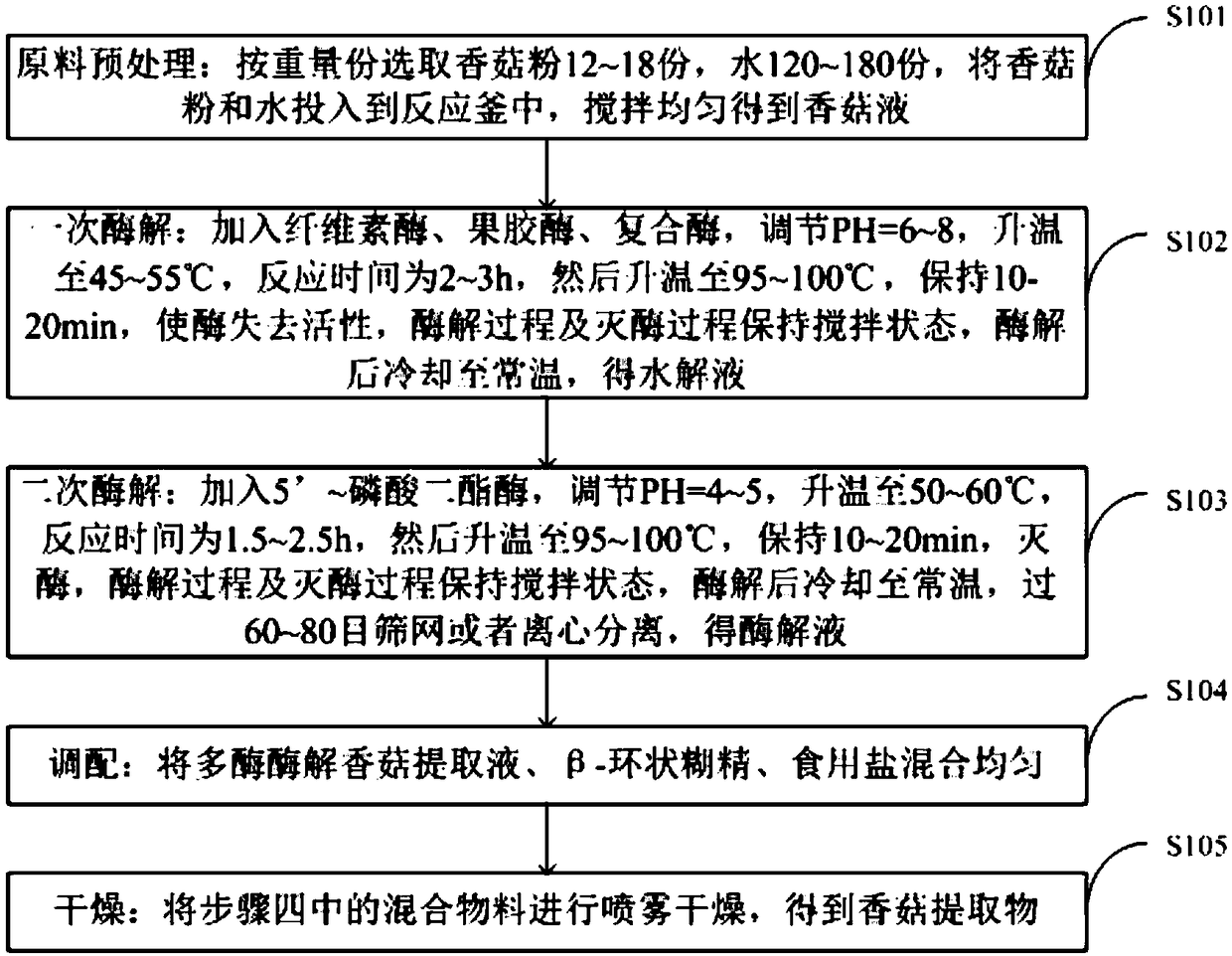

[0037] Such as figure 1As shown, the preparation method of the biological enzymolysis shiitake mushroom extract provided by the embodiments of the present invention includes:

[0038] S101, raw material pretreatment: select 12-18 parts of shiitake mushroom powder and 120-180 parts of water in parts by weight, put the shiitake mushroom powder and water into the reaction kettle, and stir evenly to obtain the shiitake mushroom liquid;

[0039] S102, one-time enzymatic hydrolysis: add cellulase, pectinase, and compound enzymes to step (1), adjust the pH to 6-8, raise the temperature to 45-55°C, the reaction time is 2-3h, and then raise the temperature to 95°C ~100°C, keep it for 10-20 minutes to inactivate the enzyme, keep stirring during the enzymolysis and deactivation process, cool to room temperature after enzymolysis, and get the hydrolyzate;

[0040] S103, secondary enzymatic hydrolysis: add 5'-phosphodiesterase to step (2), adjust the pH to 4~5, raise the temperature to 50...

Embodiment 1

[0051] Each component of the shiitake mushroom liquid is composed of 12 parts by weight of shiitake mushroom powder and 120 parts of water; each component of the multi-enzyme enzymolysis shiitake mushroom extract is composed of 132 parts by weight of shiitake mushroom liquid, 0.4 part of cellulase, and 0.2 part of pectinase, Composed of 0.2 parts of protease H, 0.1 part of flavor protease, and 0.4 part of 5'-phosphodiesterase; wherein, protease H: flavor protease = 2:1; each component of shiitake mushroom extract is extracted by multi-enzyme enzymolysis shiitake mushroom 3000 parts of liquid, 15 parts of β-cyclodextrin, and 8 parts of edible salt. The preparation method of the biological enzymolysis shiitake mushroom extract comprises:

[0052] Step (1) raw material pretreatment: according to the above weight parts, put the shiitake mushroom powder and water into the reaction kettle, stir evenly to obtain the shiitake mushroom liquid;

[0053] Step (2) Primary enzymolysis: Ad...

Embodiment 2

[0058] Each component of shiitake mushroom liquid is composed of 18 parts by weight of shiitake mushroom powder and 180 parts of water; each component of multi-enzyme enzymolysis shiitake mushroom extract is composed of 198 parts by weight of shiitake mushroom liquid, 0.8 part of cellulase, and 0.4 part of pectinase, Composed of 0.6 parts of protease H, 0.3 parts of flavor protease, and 0.8 parts of 5'-phosphodiesterase; wherein, protease H: flavor protease = 2:1; each component of shiitake mushroom extract is extracted by multi-enzyme enzymolysis shiitake mushroom 3600 parts of liquid, 20 parts of β-cyclodextrin, and 10 parts of edible salt.

[0059] The preparation method of the biological enzymolysis shiitake mushroom extract comprises:

[0060] Step (1) raw material pretreatment: according to the above weight parts, put the shiitake mushroom powder and water into the reaction kettle, stir evenly to obtain the shiitake mushroom liquid;

[0061] Step (2) Primary enzymolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com