Cold-heat-electricity triple generation meal replacement powder food energy use system

A technology of combined cooling, heating and electricity, meal replacement powder, applied in application, food science, indirect heat exchanger, etc., can solve the problems of low comprehensive utilization rate of energy, high cost of hot water and electricity, and achieve comprehensive utilization rate Improve and improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

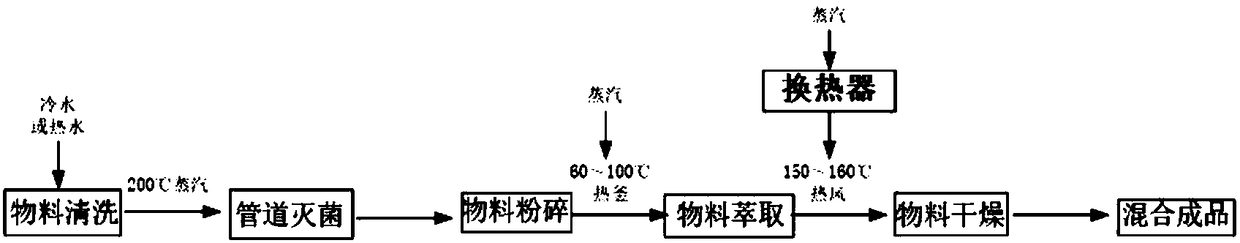

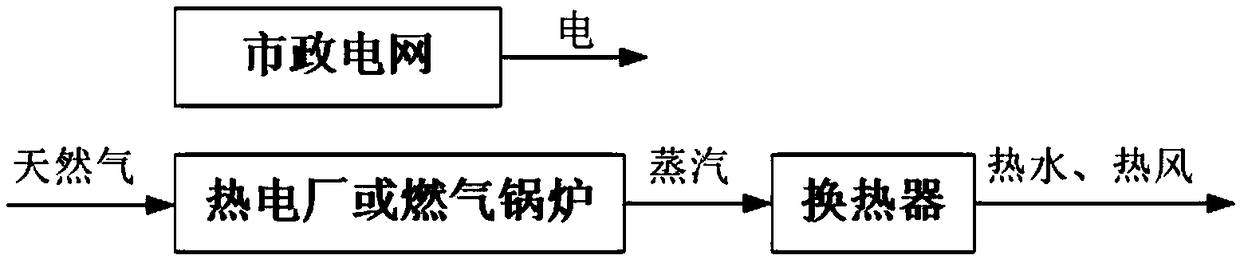

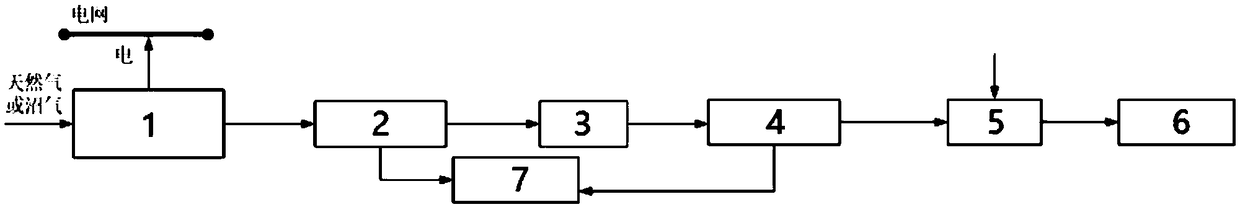

[0054] Such as figure 1 As shown, as an example, the meal replacement powder food energy system of the present invention with combined cooling, heating and power supply includes a gas turbine generator set 1, an extraction kettle 2, a flue gas / air mixer 3, a material drying tower 4, and a smoke Air / water heat exchanger 5, material cleaning unit 6, fertilizer making unit 7. Among them, the gas turbine generator set 1 uses fuel to generate electricity and high-temperature flue gas, and the electricity is at least delivered to the power-consuming components in the system or to the power grid, and the high-temperature flue gas is transported to the extraction kettle 2 through pipelines; the extraction kettle 2. It is installed downstream of the gas turbine generator set 1. The extraction kettle 2 is a hollow container with an interlayer water exchange jacket. The hollow container is used to store the materials to be extracted. The gas outlet, the high-temperature flue gas outlet ...

Embodiment 2

[0060] Such as figure 1 As shown, as another example, the energy utilization system for meal replacement powder food of the present invention, the high-temperature flue gas entering the extraction kettle 2 still adopts traditional steam, and the steam used is provided by the high-temperature flue gas at the rear end of the generator set. The gas is produced through waste heat boiler 8. The temperature of the flue gas after passing through the waste heat boiler 8 is about 160-170°C, and after passing through the flue gas / air mixer 3, it can be directly sent to the dry material drying tower 4 for use. The rest of the links are similar to Example 1.

[0061] The contents involved in the present invention are all summarized for the actual case of a large-scale meal replacement powder food processing factory. The food factory builds a 2MW gas turbine generator set for the meal replacement powder production line with an annual output of 5300-8100 tons, and is equipped with a 2MW e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com