A leftover food processor system

A processing machine and leftover technology, applied in grain processing, solid waste removal, etc., can solve problems such as inability to meet family needs, slow processing of leftovers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The leftover processor system of this embodiment includes a leftover processor and a monitoring system.

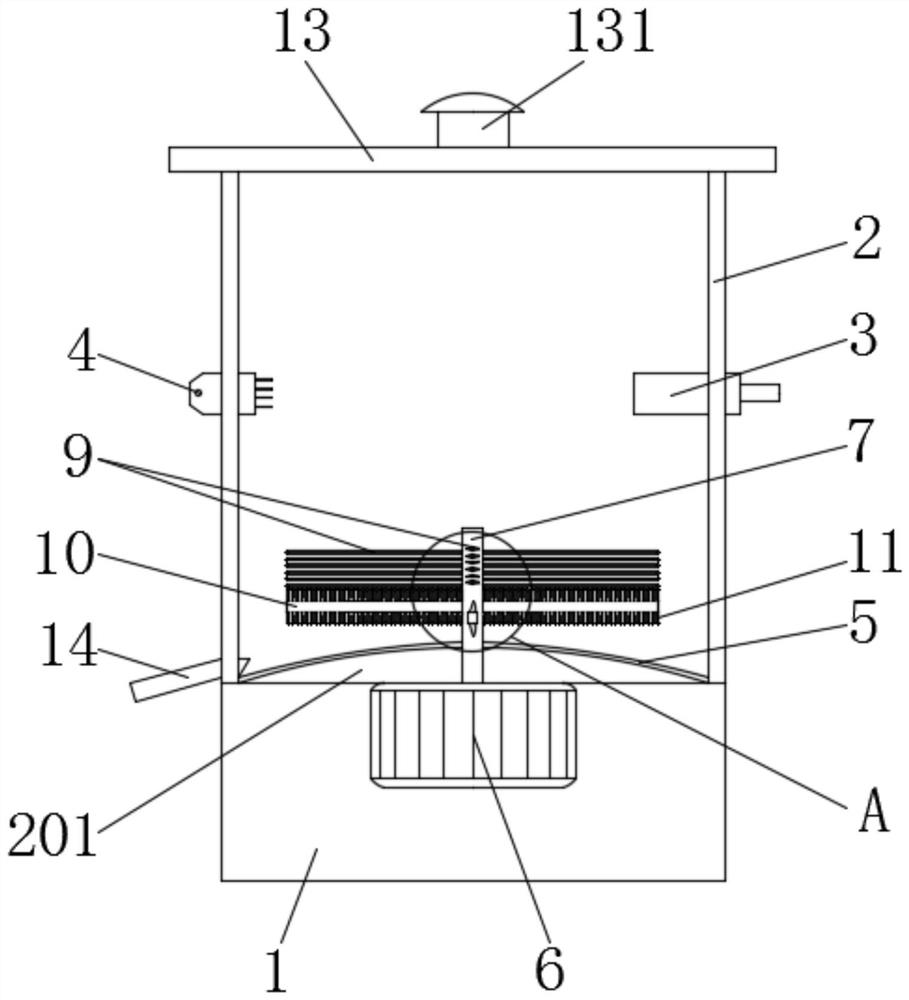

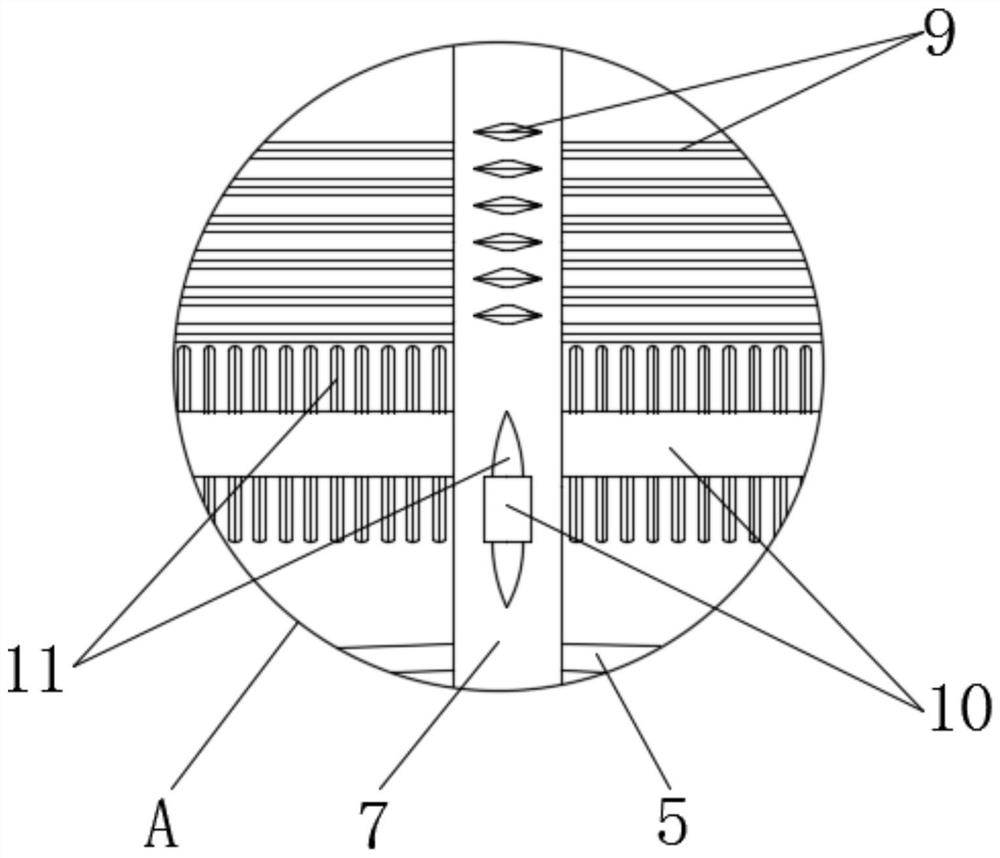

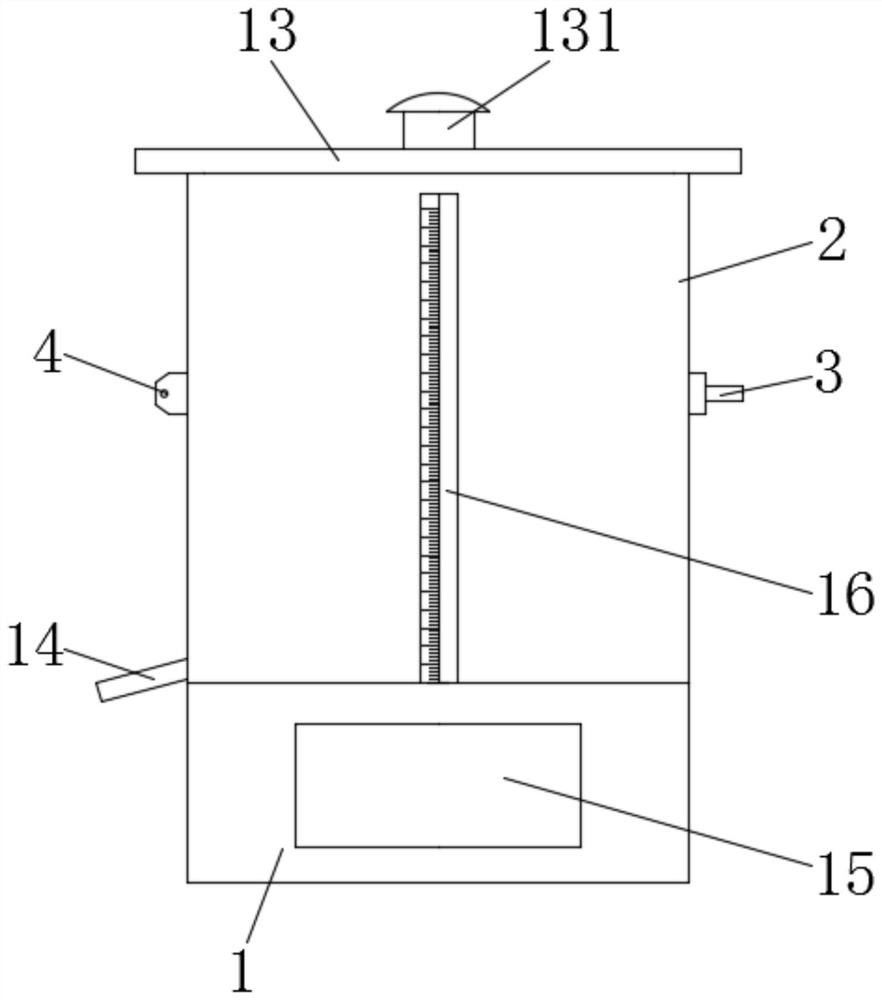

[0051] see figure 1 as well as figure 2 , The leftovers processing machine includes a base 1, a barrel body 2, a barrel cover 13, a discharge pipe 14, a display screen 15, a glass scale bar 16, a heating module, and a crushing and stirring device.

[0052] The base 1 is a cuboid or a cube. The barrel body 2 is in the shape of a barrel and is mounted on the base 1 . The bucket cover 13 is installed on the top of the bucket body 2 and has a gas exchange port 131 in the center. The gas exchange port 131 is used for exchanging the gas inside and outside the barrel body 2, so as to keep the air in the barrel body 2 clean, thereby improving the decomposition efficiency of microorganisms.

[0053] The bottom of the barrel body 2 adopts an upwardly disposed convex body 201 . One end of the discharge pipe 14 is inserted into the barrel body 2 and is located at the lowe...

Embodiment 2

[0071] see Figure 8 , the leftover processor system of this embodiment is similar to Embodiment 1, the difference is that the monitoring system of this embodiment also includes a mobile phone client. The mobile phone client uses Java language programming to complete the design in the Eclipse development environment, and has functions such as user login, real-time data query, historical data query, scientific advice, and degradation information. The main function of the mobile phone client is to provide users with a remote monitoring platform. Users can remotely monitor the operation of the leftover processor, understand the degradation of food waste anytime, anywhere, and provide users with a data analysis platform for relevant analysis and processing. Improve the processing efficiency of leftovers.

Embodiment 3

[0073] see Figure 9 , The leftover rice processor system of this embodiment is similar to Embodiment 1, the difference is that the pulverizing and stirring device of this embodiment also includes a cutting head 8 . The cutting head 8 is conical, and the apex is set upward. A plurality of evenly distributed serrations are provided on the conical surface of the cutting head 8 , and the top end of the rotating shaft 7 is inserted into the cutting head 8 along the central axis of the cutting head 8 and fixed with the cutting head 8 . In this embodiment, the conical cutting head 8 is used to pre-cut the leftovers put in, so that the whole piece of leftovers is dispersed, and the blocky leftovers are decomposed before horizontal cutting and vertical cutting, so as to improve the quality of leftovers. High crushing efficiency, speed up the decomposition of leftovers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com