Platinum nano-particles and preparation method thereof

A platinum nanoparticle, potassium chloroplatinite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of limited ability, small size of platinum nanoparticles, and difficulty in preparing platinum nanoparticles and other problems, to achieve the effect of eliminating energy consumption and broadening the size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Dissolve 280 mg of tetra-n-octylammonium bromide and 15 mg of four-generation dendritic polyamidoamines containing 12 carbon atom long-chain alkanes at the end in 5 ml of toluene, while dissolving 100 mg of potassium chloroplatinite in 5 ml In water; After the two solutions were mixed and vigorously stirred for 0.5 hours, the layers were statically separated and the upper layer liquid was collected; the upper layer liquid was transferred to the reactor, then reacted under a hydrogen atmosphere for 48 hours, and centrifuged at 12000 rpm for 5 minutes to obtain platinum nanoparticles.

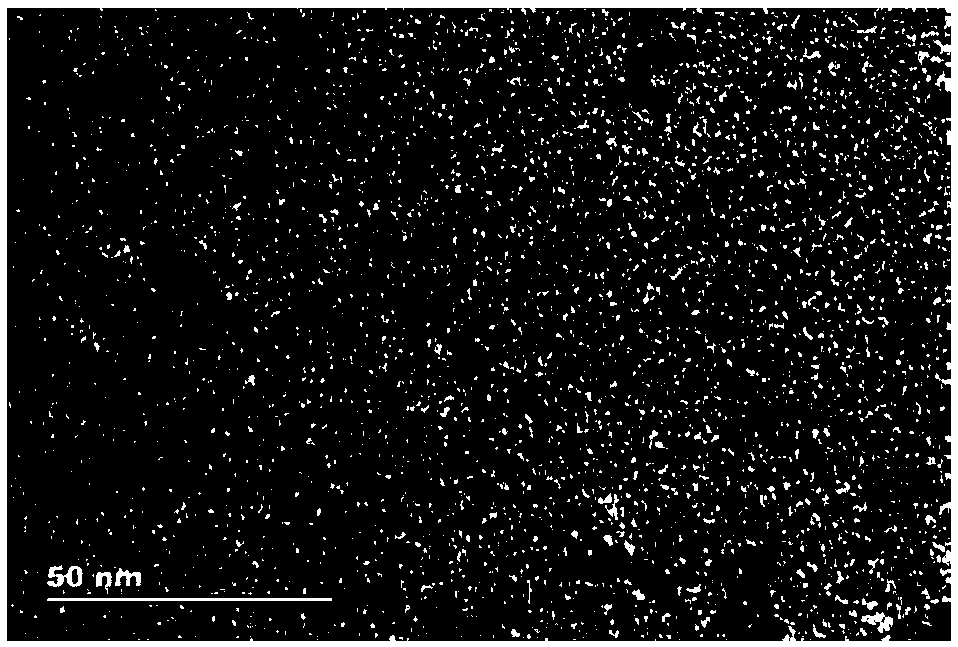

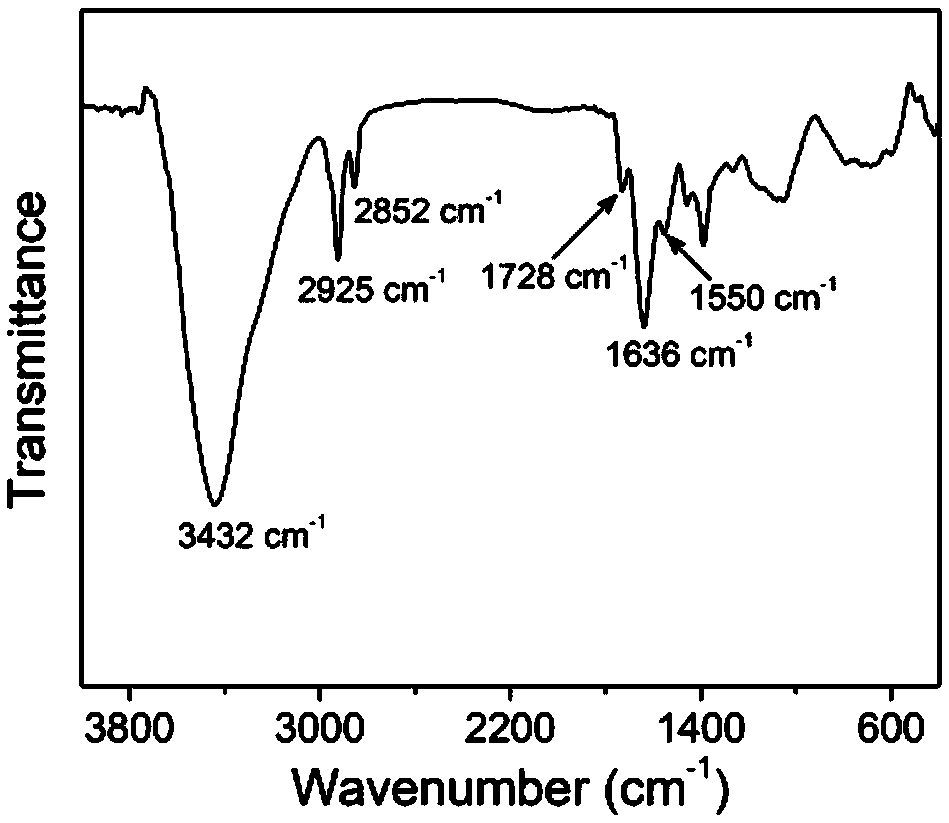

[0023] figure 1 It is a transmission electron micrograph of the platinum nanoparticles prepared in the above example, and the average diameter of the platinum nanoparticles is measured to be 3.1 nanometers. figure 2 The Fourier transform infrared spectrogram of the platinum nanoparticle that above-mentioned embodiment makes, wherein 3432 cm -1 The peak at -NH- vibration peak, 2925cm -1...

example 2

[0025] 22 mg of tetra-n-octylammonium bromide and 30 mg of three-generation dendritic polyamidoamines containing 8 carbon atom long-chain alkanes at the end were dissolved in 5 ml of toluene, while 25 mg of potassium chloroplatinite was dissolved in 5 ml of water ; After mixing the two solutions and vigorously stirring for 2 hours, static layering and collecting the upper liquid; the upper liquid was transferred to the reactor, then reacted under a hydrogen atmosphere for 96 hours, and centrifuged at 10,000 rpm for 10 minutes to obtain platinum nanoparticles.

[0026] The platinum nanoparticles prepared in the above examples were characterized by a transmission electron microscope, and the average diameter of the platinum nanoparticles was obtained to be 2.0 nanometers.

example 3

[0028] Dissolve 528 mg of tetra-n-octylammonium bromide and 30 mg of six-generation dendritic polyamidoamines containing 18 carbon atom long-chain alkanes at the end in 5 ml of toluene, while dissolving 500 mg of potassium chloroplatinite in 5 ml In water; After mixing the two solutions and vigorously stirring for 1 hour, the layers were statically separated and the upper layer liquid was collected; the upper layer liquid was transferred to the reactor, then reacted under a hydrogen atmosphere for 72 hours, and centrifuged at 5000 rpm for 30 minutes to obtain platinum nanoparticles.

[0029] The platinum nanoparticles prepared in the above examples were characterized by a transmission electron microscope, and the average diameter of the platinum nanoparticles was 6.0 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com