Preparation method of NbSe2 electrode material as well as product and application of NbSe2 electrode material

A technology of electrode material and selenium powder, which is applied in the field of materials, can solve problems such as depletion, and achieve the effects of high capacity, low cost of preparation process, and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Firstly, the metal niobium powder and the metal selenium powder are ground separately, and after grinding and sieving, a powder of 20nm-2μm is obtained, and the niobium powder and the selenium powder are mixed evenly according to the molar ratio of 1:2, then added to ethanol, dispersed evenly, and mixed with the added ethanol Evenly form mixed solution, the volume of the ethanol that adds and the ratio of the total substance amount of niobium powder and selenium powder are 1:2.5, L:mol; Next mixed solution is put into ball mill tank, and setting ball mill speed is 300r / min, Take it out after ball milling for 8 hours; finally pour the milled solution into a covered porcelain boat, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 750°C at a heating rate of 10°C / min, and sinter it for 1.5h. The tube furnace was lowered to room temperature, and the brown powder obtained by sintering was collected, that is, NbSe 2 electrode mater...

Embodiment 2

[0031] First, the metal niobium particles and the metal selenium particles are ground separately, and after grinding and sieving, a powder of 20nm-2μm is obtained, and the niobium powder and the selenium powder are mixed evenly according to the molar ratio of 1:2.05, and then added to an organic solvent to disperse evenly. Add ethanol, the ratio of the volume of the added ethanol to the total amount of the niobium powder and the selenium powder is 1:3, L:mol; secondly, put the mixed solution into the ball mill tank, set the ball mill speed to 400r / min, and ball mill for 10h Finally, take it out; finally pour the ball-milled solution into a covered porcelain boat, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 750 °C at a rate of 10 °C / min. After sintering for 2 hours, put the tube furnace into Cool down to room temperature, collect the brown powder obtained by sintering, that is, NbSe 2 electrode material.

Embodiment 3

[0033] First, the metal niobium block and the metal selenium block are ground separately, and after grinding and sieving, a powder of 20nm-2μm is obtained, and the niobium powder and the selenium powder are mixed evenly according to the molar ratio of 1:2.1, and then added to an organic solvent to disperse evenly. The ethanol that adds, the ratio of the volume of the ethanol that adds and the total substance amount of niobium powder and selenium powder are 1:3.6, L:mol; Next mixed solution is put into the ball mill pot, ball mill speed is set to be 500r / min, ball mill Take it out after 12 hours; finally pour the ball-milled solution into a covered porcelain boat, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 750 °C at a rate of 10 °C / min, and sinter for 2.5 hours. The furnace was lowered to room temperature, and the brown powder obtained by sintering was collected, that is, NbSe 2 electrode material.

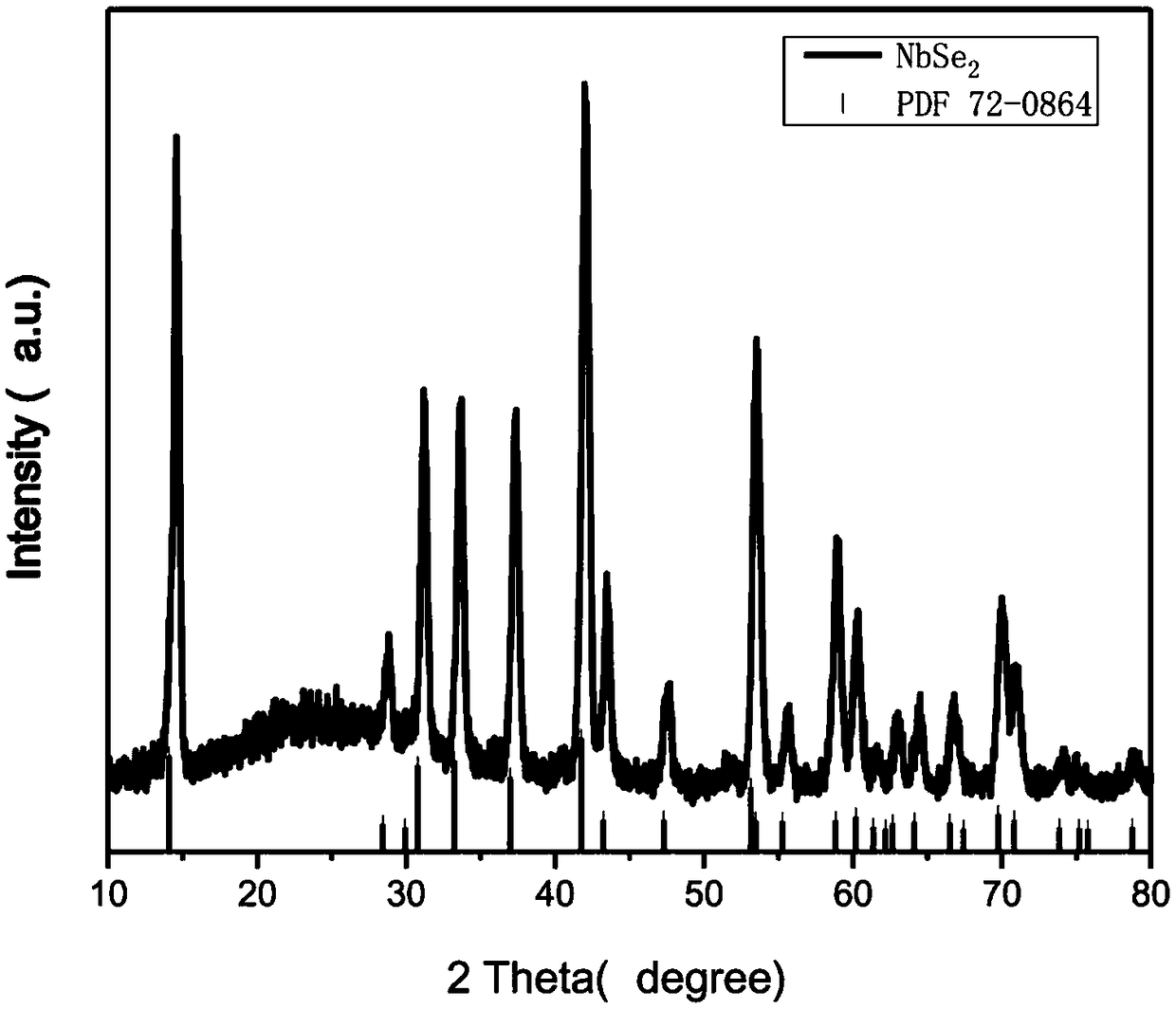

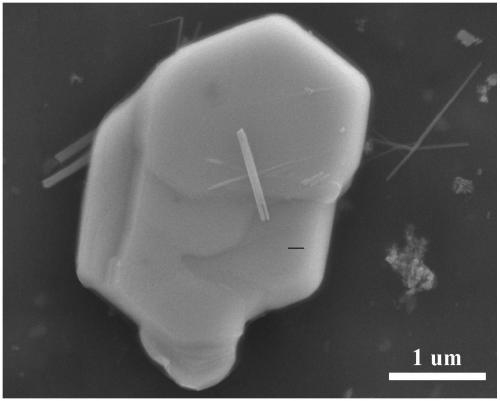

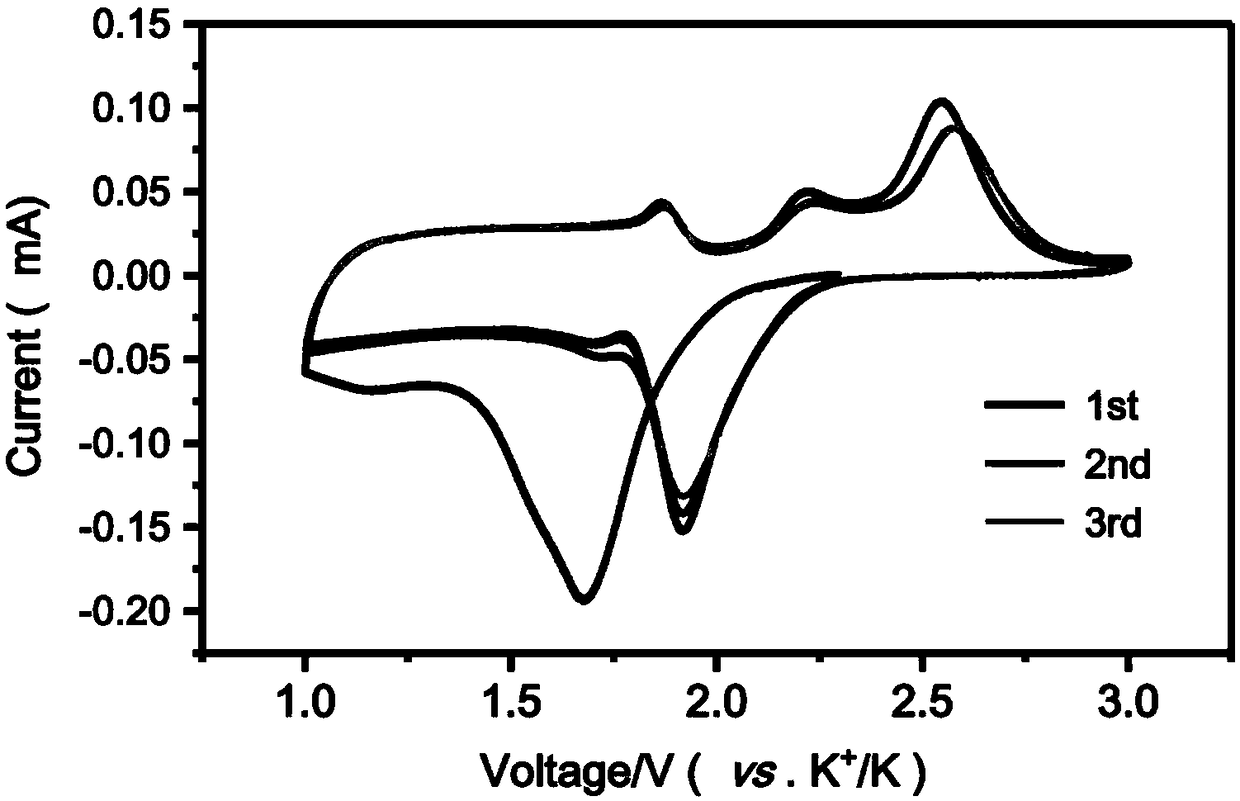

[0034] NbSe 2 Characteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge capacity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com