Method for preparing graphite by using hydraulic cavitation liquid-phase stripping

A liquid phase exfoliation and graphene technology, applied in the directions of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of low exfoliation efficiency, low output and high equipment requirements, and achieve easy large-scale industrial production, The effect of low production cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

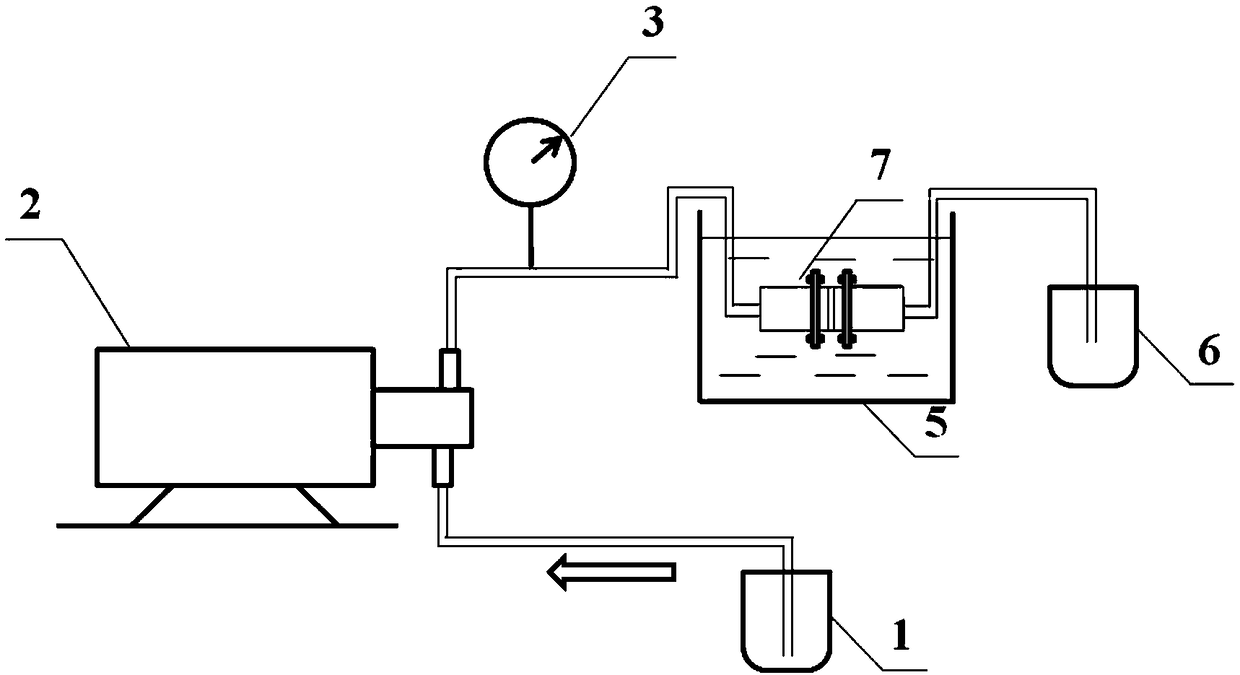

[0036] Combined with the manual figure 2 The technical scheme of the present invention is reacted in a self-made device: the device includes a raw material tank 1, a pump 2, a pressure gauge 3, an orifice 7 and a product tank 5, and the feed inlet of the pump 2 is connected to the raw material The tank 1 is connected, the discharge port is connected with the inlet of the orifice 7, and the outlet of the orifice 7 is connected with the product tank 6; the pressure gauge 3 is immersed in the constant temperature water bath 5; the pump 2 A pressure gauge 3 is provided on the connecting pipeline with the orifice plate 7; both ends of the orifice plate 7 are connected to the pipeline through flanges.

[0037] 1) Take pure isopropanol as solvent, Tween 80 as surfactant, configure graphite concentration as the dispersion liquid of 3g / L, surfactant concentration 0.5g / L, fully stir, obtain graphite dispersion liquid;

[0038] 2) Use a pump to send the graphite dispersion liquid at a ...

Embodiment 2

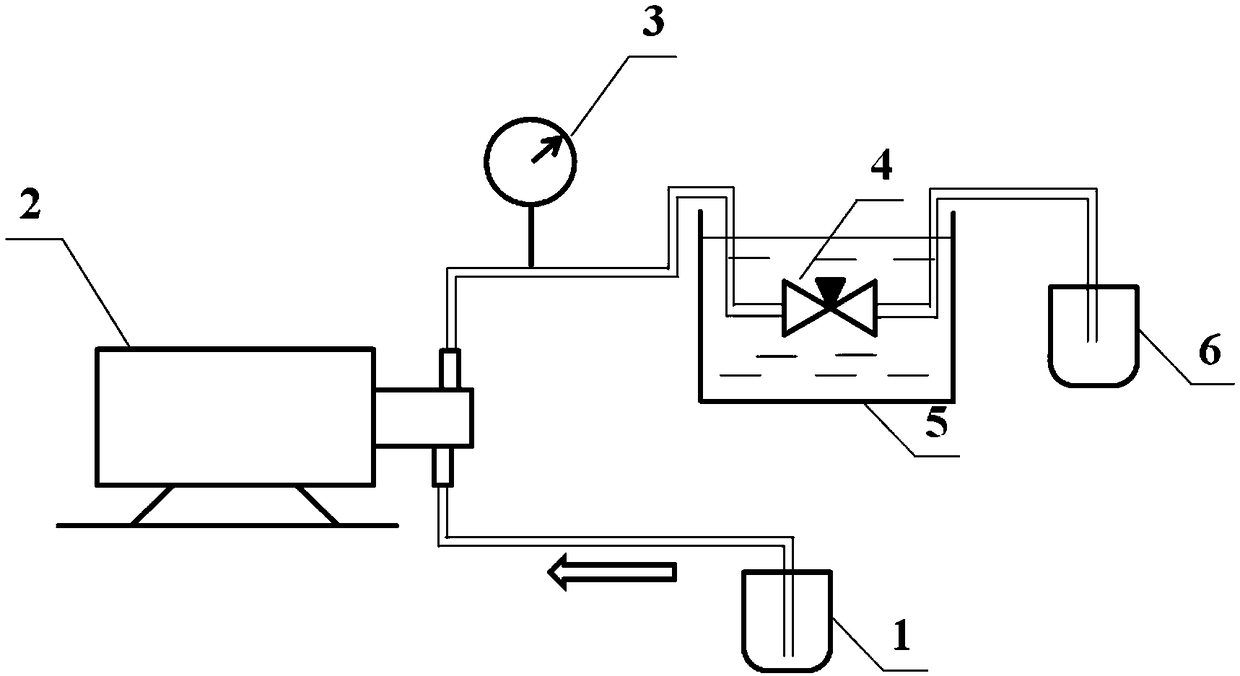

[0041] Combined with the manual figure 1The technical scheme of the present invention reacts in a self-made device: the device comprises a raw material tank 1, a pump 2, a pressure gauge 3, a valve 4 and a product tank 5, and the feed inlet of the pump 2 and the raw material tank 1 connection, the discharge port is connected with the inlet of the valve 4, and the outlet of the valve 4 is connected with the product tank 6; the pressure gauge 3 is immersed in the constant temperature water bath 5; the pump 2 and the valve 4 A pressure gauge 3 is provided on the connecting pipeline.

[0042] 1) Take pure N-methylpyrrolidone as a solvent and sodium taurodeoxycholate as a surfactant, configure a dispersion with a graphite concentration of 30 g / L and a surfactant concentration of 0.1 g / L, and fully stir to obtain a graphite dispersion;

[0043] 2) Use a pump to send the graphite dispersion at a flow rate of 1L / h into a valve with an opening of 0.02mm, maintain the cavitation pressu...

Embodiment 3

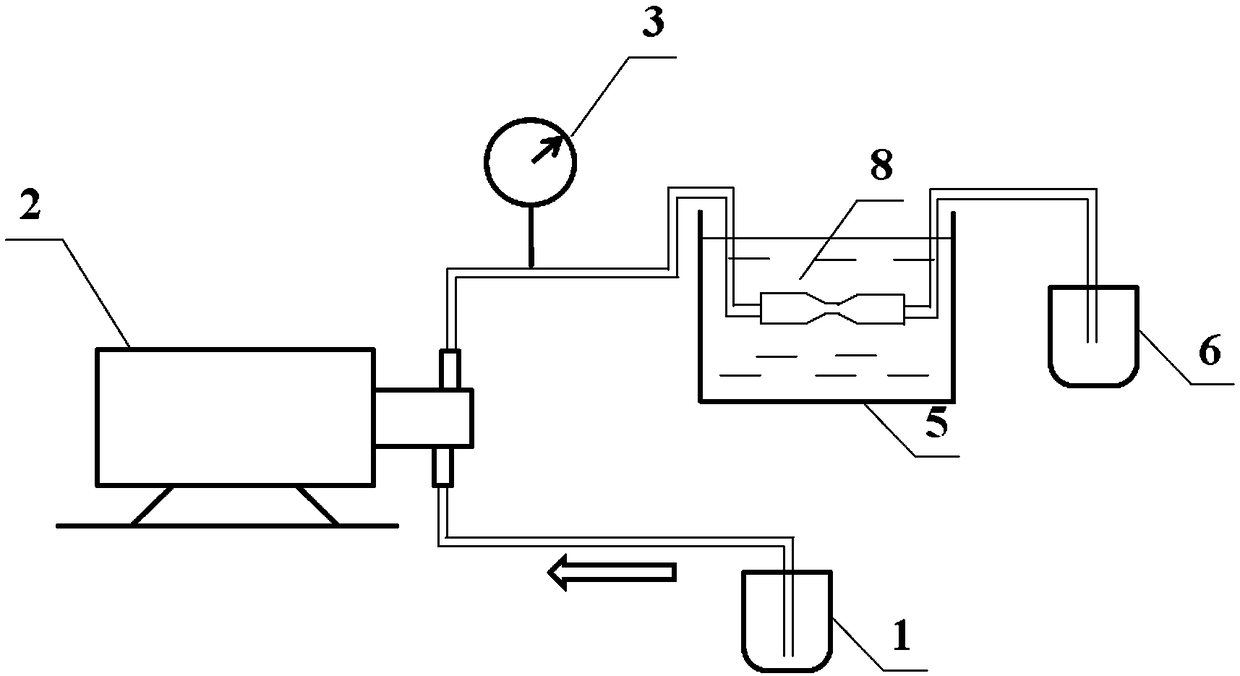

[0046] Combined with the manual image 3 The technical scheme of the present invention reacts in the self-made device: described device comprises raw material tank 1, pump 2, pressure gauge 3, Venturi tube 8 and product tank 5, and the inlet of described pump 2 and The raw material tank 1 is connected, the outlet is connected with the inlet of the Venturi tube 8, and the outlet of the Venturi tube 8 is connected with the product tank 6; the pressure gauge 3 is immersed in the constant temperature water bath 5; A pressure gauge 3 is provided on the connecting pipeline between the pump 2 and the Venturi tube 8 .

[0047] 1) Take the N-methylpyrrolidone-water mixed solution with a volume ratio of 2:1 as the solvent, sodium dodecylbenzenesulfonate as the surfactant, configure the graphite concentration as 50g / L, and the surfactant concentration as 0.1g / L The dispersion of L is fully stirred to obtain a graphite dispersion;

[0048] 2) Use a pump to send the graphite dispersion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com