Deep cooling and separating method of low-carbon olefin gas

A low-carbon olefin and cryogenic separation technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve the problem of high content of alkynes and dienes, which cannot meet the demand, and the pressure of syngas is low, etc. problem, to achieve the effect of improving recovery rate, increasing use value and reducing ethylene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

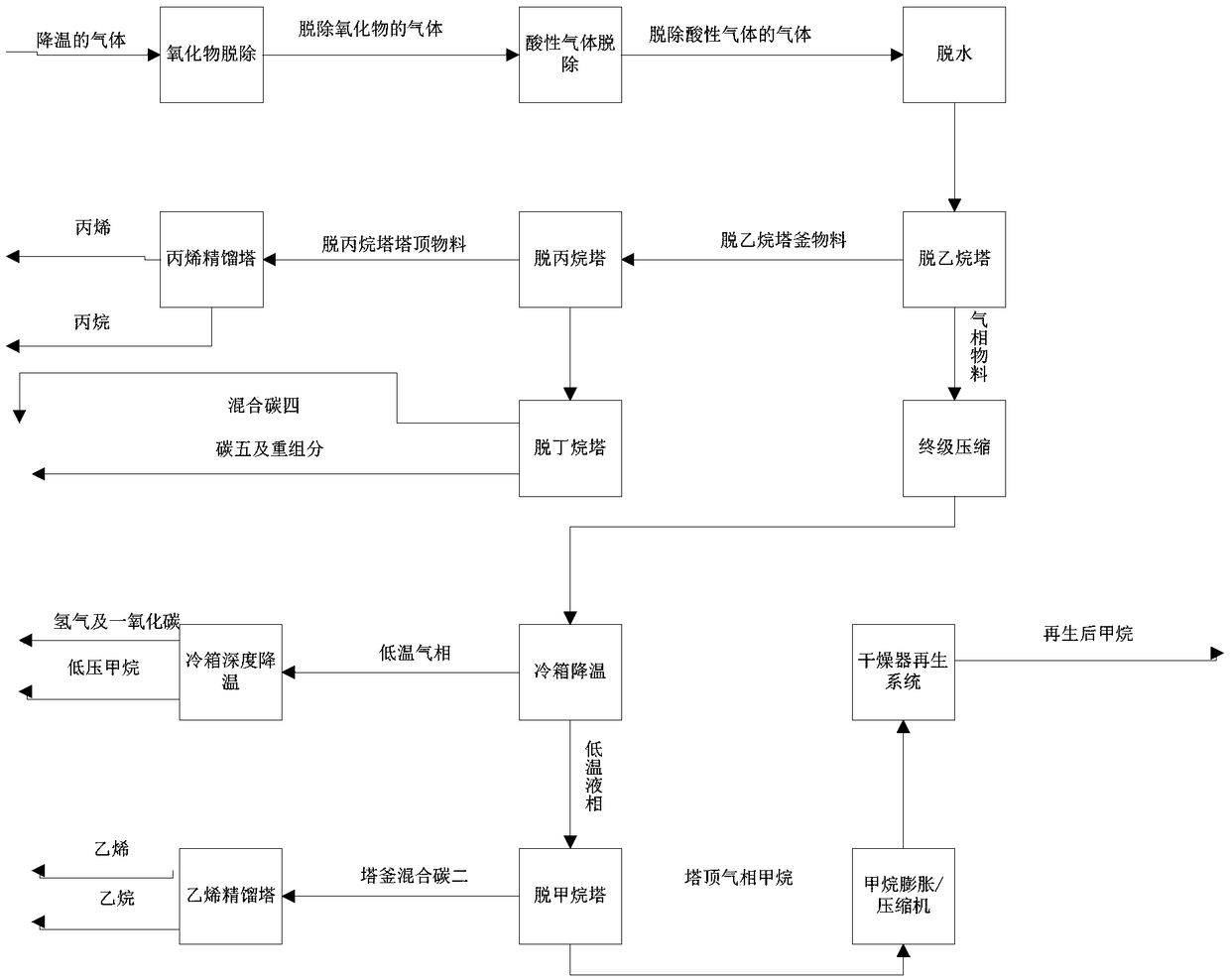

[0030] Such as figure 1 As shown, the invention discloses a cryogenic separation method of low-carbon olefin gas, comprising the following steps:

[0031] (1) The low-carbon olefin gas coming out of the synthesis gas-to-olefin reactor has a certain pressure (1-3MPA or even higher) and temperature (200-300°C), and enters the oxide after step-by-step cooling (about 40°C) Removal system to remove organic oxides (ketones, aldehydes, alcohols, ethers, etc.) contained in the product gas;

[0032] (2) The low-carbon olefin gas for oxide removal selects different acid gas removal methods according to the content and type of acid gas, and can use MDEA (methyldiethanolamine), sodium hydroxide solution, etc. for washing or molecular sieve adsorbent selectivity Adsorption; when the acid gas is only a small amount of carbon dioxide, molecular sieve adsorbent is used to remove carbon dioxide. The carbon dioxide adsorbent can be installed in the same adsorption container as the 3A molecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com