Papyraceous gradient microfiber composite metal organic framework material as well as preparation method and application thereof

A technology of composite metal and organic framework, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of discontinuous MOFs film, easy separation of crystal and carrier, and difficult to cut and fold the carrier, and achieve chemical stability and heat transfer. Good performance, adjustable mechanical strength, adjustable porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

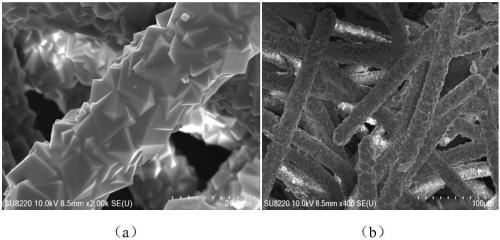

[0032] (1) Preparation of paper-like sintered stainless steel fiber carrier:

[0033] Add 6g of stainless steel fiber and 3g of coniferous wood fiber into the water, and stir at high speed for 10 minutes in a fiber standard dissociator to form a uniform slurry, in which the diameter of the stainless steel fiber is 6.5 μm, fry the evenly mixed slurry with a slicer, After filtering, a wet filter cake is formed, the filter cake is pressed, dried at 105°C for 2h, and the dried stainless steel fiber carrier precursor is sintered at 1050°C for 40min under nitrogen protection gas with a flow rate of 2000mL / min. Prepared paper-like sintered stainless steel fiber carrier (thickness is 2mm);

[0034] (2) Modification of paper-like sintered stainless steel fiber carrier:

[0035] Cut the paper-like sintered stainless steel fiber carrier (PSSF) into a rectangle of 4cm*5cm, sonicate 3 times with deionized water, 5 minutes each time, and 3 times with absolute ethanol, 5 minutes each time; ...

Embodiment 2

[0046] Except following difference, all the other are with embodiment 1:

[0047] The quality of 2-methylimidazole in step (3) is 0.5747g.

Embodiment 3

[0049] Except following difference, all the other are with embodiment 1:

[0050] The reaction time in step (3) is 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com