Quaternary blending modified alloy material containing polyether-ether-ketone as well as preparation method and application thereof

A polyetheretherketone and alloy material technology, which is applied in the field of quaternary blending modified alloy material and its preparation, can solve the problems of low glass transition temperature Tg, limited application, insufficient rigidity and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

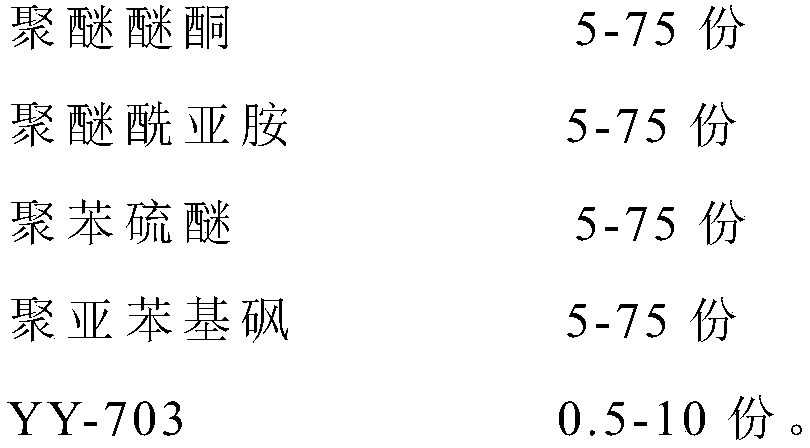

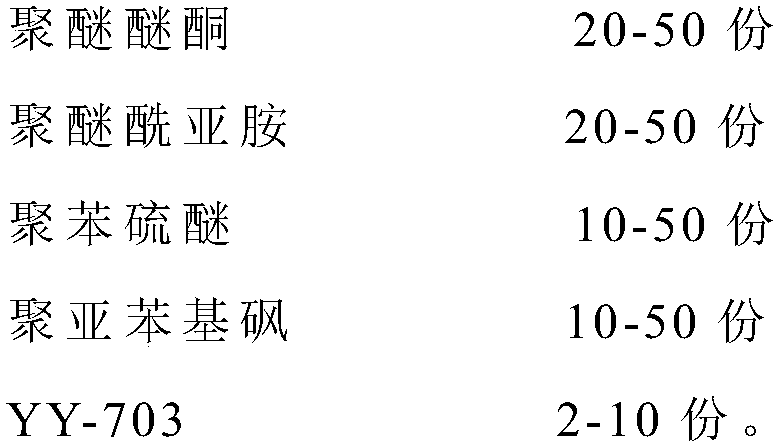

Method used

Image

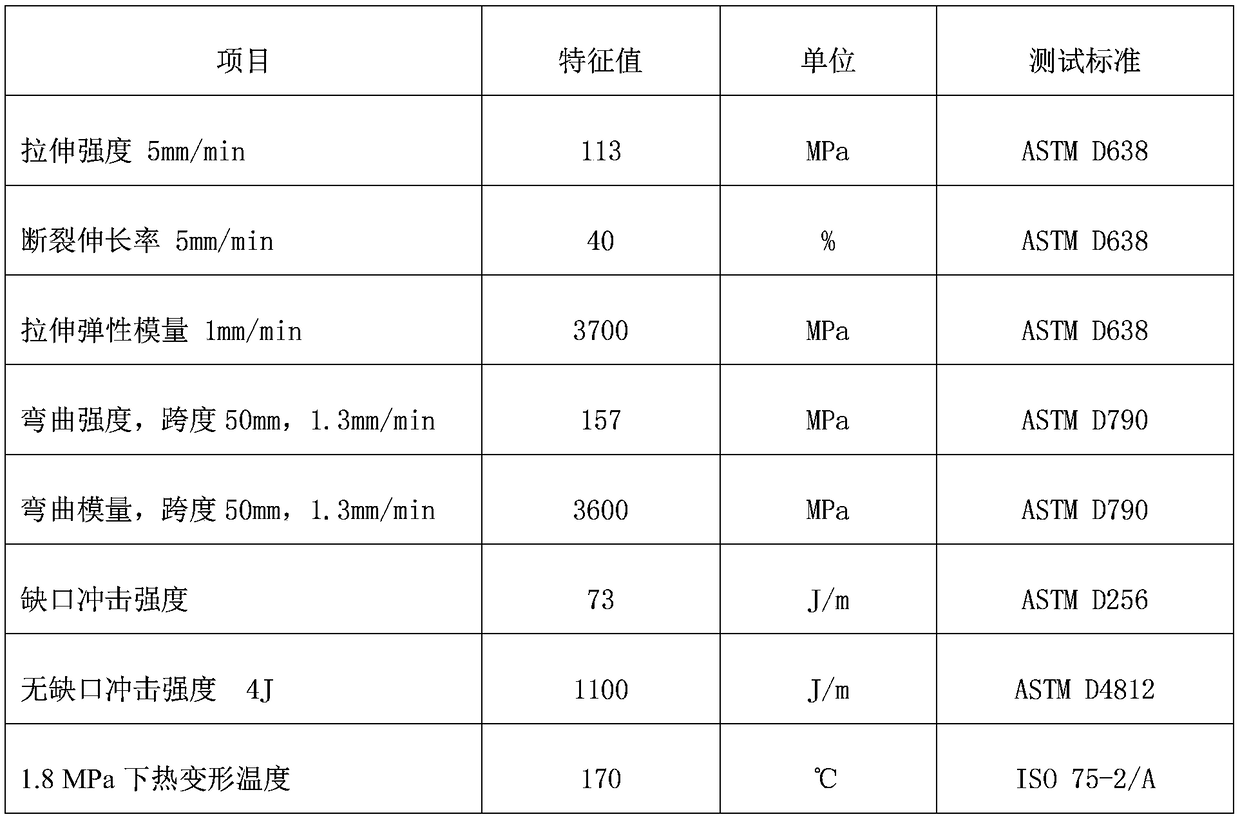

Examples

Embodiment 1

[0034] This embodiment provides a quaternary blend modified alloy material containing polyetheretherketone, the raw materials of which include: 40 parts of polyetheretherketone; 30 parts of polyetherimide; 30 parts of polyphenylene sulfide; polyphenylene 30 parts of base sulfone; 30 parts of toughening agent; 8 parts of compatibilizer (YY-703 of Guangzhou Yuantai Synthetic Materials Co., Ltd.); 5 parts of stabilizer.

[0035] Its preparation method is:

[0036] a. Put 40 parts of polyether ether ketone, 30 parts of polyetherimide, 30 parts of polyphenylene sulfide, and 30 parts of polyphenylene sulfone into an oven, set the temperature at 150 degrees, and dry for 4 hours;

[0037] b. Put 40 parts of dried polyetheretherketone, 30 parts of polyetherimide, 30 parts of polyphenylene sulfide, 30 parts of toughening agent, 5 parts of compatibilizer and 3 parts of stabilizer into the mixer Mix for 10 minutes; then put the mixture into the extruder for melt extrusion. 365°C in the ...

Embodiment 2

[0045] This embodiment provides a quaternary blend modified alloy material containing polyetheretherketone, the raw materials of which include: 20 parts of polyetheretherketone; 50 parts of polyetherimide; 40 parts of polyphenylene sulfide; polyphenylene 20 parts of base sulfone; 20 parts of toughening agent; 10 parts of compatibilizer (YY-703 of Guangzhou Yuantai Synthetic Materials Co., Ltd.); 5 parts of stabilizer.

[0046] Its preparation method is:

[0047] a. Put 20 parts of polyether ether ketone, 50 parts of polyetherimide, 40 parts of polyphenylene sulfide, and 20 parts of polyphenylene sulfone into an oven, set the temperature at 150 degrees, and dry for 4 hours;

[0048] b. Put 20 parts of dried polyether ether ketone, 50 parts of polyetherimide, 40 parts of polyphenylene sulfide, 20 parts of toughening agent, 8 parts of compatibilizer and 3 parts of stabilizer into the mixer Mix for 10 minutes; then put the mixture into the extruder for melt extrusion. 365°C in t...

Embodiment 3

[0056] This embodiment provides a quaternary blend modified alloy material containing polyetheretherketone, the raw materials of which include: 50 parts of polyetheretherketone; 10 parts of polyetherimide; 20 parts of polyphenylene sulfide; polyphenylene 40 parts of base sulfone; 30 parts of toughening agent; 10 parts of compatibilizer (YY-703 of Guangzhou Yuantai Synthetic Materials Co., Ltd.); 6 parts of stabilizer.

[0057] Its preparation method is:

[0058] a. Put 50 parts of polyether ether ketone, 10 parts of polyetherimide, 20 parts of polyphenylene sulfide, and 40 parts of polyphenylene sulfone into an oven, set the temperature at 150 degrees, and dry for 4 hours;

[0059] b. Put 50 parts of dried polyetheretherketone, 10 parts of polyetherimide, 20 parts of polyphenylene sulfide, 30 parts of toughening agent, 5 parts of compatibilizer and 3 parts of stabilizer into the mixer Mix for 10 minutes; then put the mixture into the extruder for melt extrusion. 365°C in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap