Low-VOC and double-component solvent type top finish and preparation method thereof

A two-component, solvent-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of high VOC content and viscosity, slow drying speed, etc., achieve low construction viscosity, increase drying speed, and reduce viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

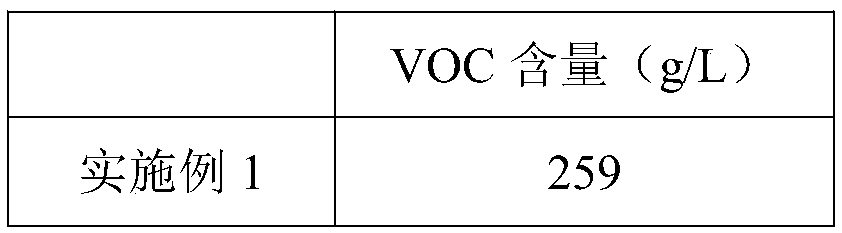

Examples

Embodiment 1-4

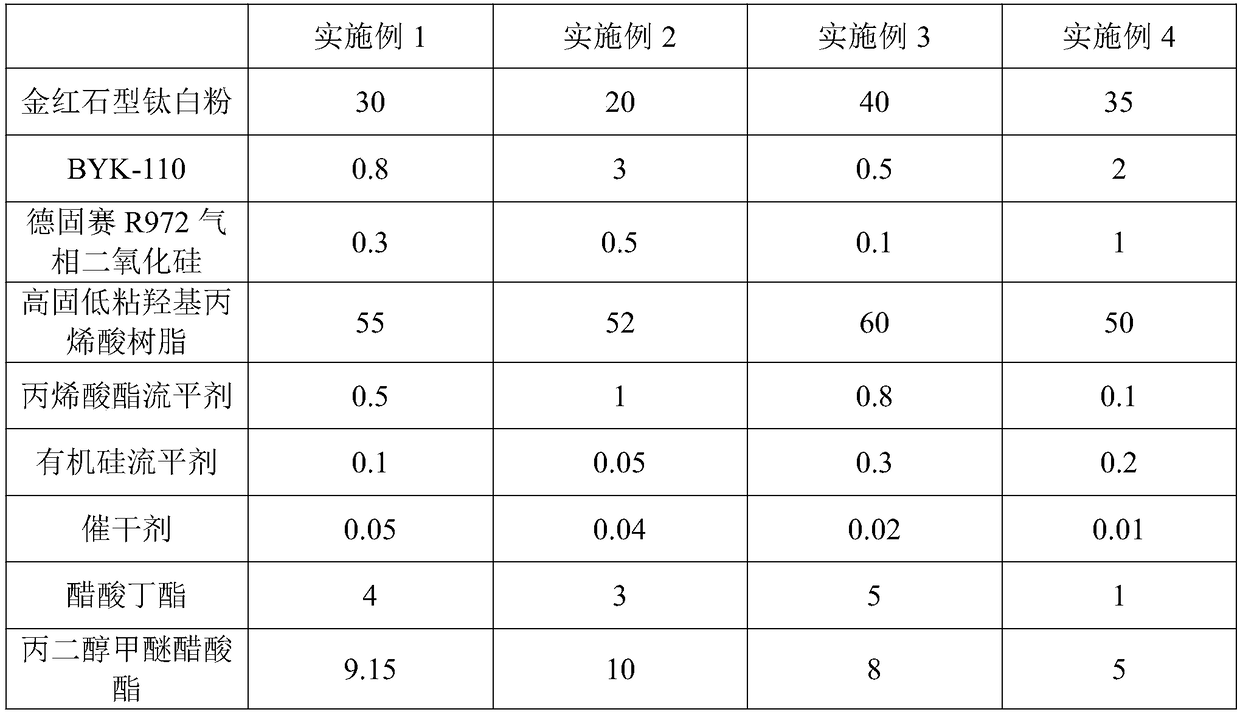

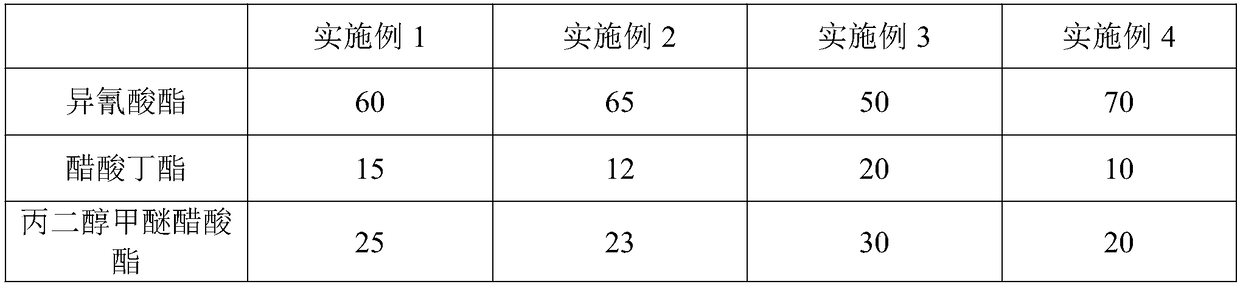

[0034] According to the ratio (in parts by weight) of table 1, prepare the first component of the top paint, according to the ratio in table 2 (in parts by weight), prepare the second component of the top paint, the weight ratio of the first component and the second component is 1 :1:

[0035]

[0036] Table 1

[0037] Wherein, the drier is composed of organotin drier and fatty acid zinc in a weight ratio of 2:1. The preparation steps of fatty acid zinc are:

[0038] A1. Place the okra seeds in an oven at 60°C to dry to constant weight, take them out and crush them, pass through a 50-mesh sieve to get the okra seed powder, add the okra seed powder to 10 times the weight of petroleum ether, and put In a microwave oven with a power of 600W, extract by microwave for 10 minutes to obtain an extract, filter the extract with suction to obtain a filtrate, concentrate the filtrate under reduced pressure and dry it to a constant weight at 100°C to obtain a fatty acid;

[0039] A2...

Embodiment 1

[0040] The preparation steps of the first component of embodiment 1 are:

[0041] B1. each component is taken by weight, butyl acetate and propylene glycol methyl ether acetate are added in the stirring tank, and stirred for 4 minutes at 400 rpm;

[0042] B2. Add the wetting and dispersing agent into the stirring tank, and stir for 4 minutes at 400 rpm;

[0043] B3. Add the acrylic resin to the stirring tank, and stir for 4 minutes at 400 rpm;

[0044] B4. Add titanium dioxide and anti-sedimentation agent into the stirring tank, stir at 1400 rpm for 30 minutes until the fineness of the mixed material is lower than 15 μm, and stop stirring;

[0045] B5. Add other components into the stirring tank, and stir for 10 minutes at 400 rpm to obtain component A.

Embodiment 2

[0046] The preparation steps of the first component of embodiment 2 are different from embodiment 1: the rotating speed in steps B1, B2, B3 is 390 rev / min, and the stirring time is 5 minutes; the rotating speed in step B4 is 1390 rev / min minutes, the stirring time was 40 minutes; the rotating speed in step B5 was 390 rpm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap