Nicotinamide-containing handmade soap and preparation method thereof

A technology of niacinamide and handmade soap, which is applied in skin care preparations, chemical instruments and methods, soap detergents and other compounding agents, etc., can solve the problems of discoloration and easy loss of stability of soap preparations, and achieve long-term preservation and maintenance. , Improves skin barrier, treats acne

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

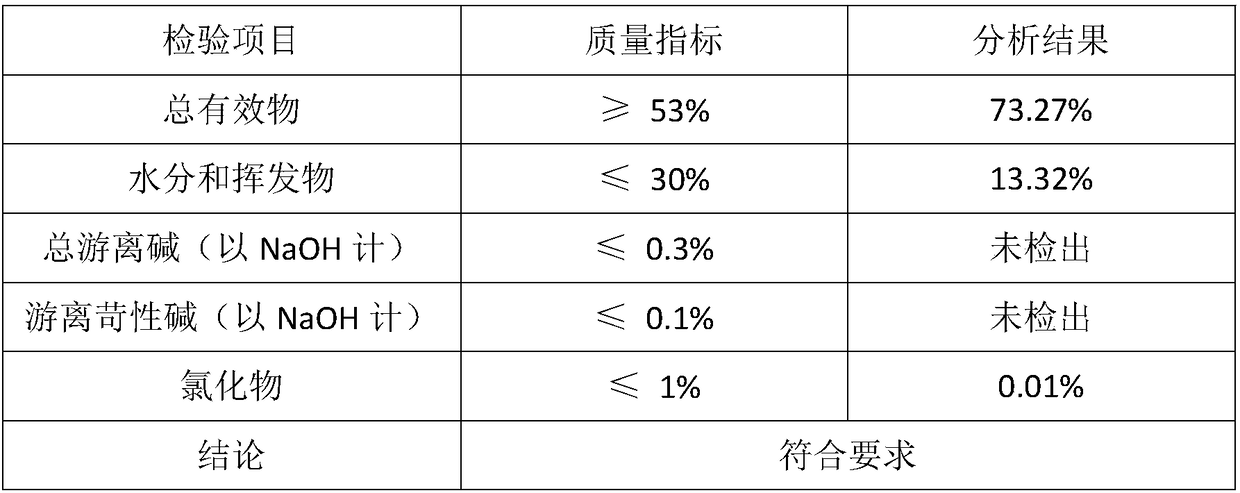

Image

Examples

Embodiment 1

[0049] Mix 200g palm oil (saponification value 0.142gNaOH / g), 200g coconut oil (saponification value 0.19gNaOH / g) 66.2 and 600g soybean oil (saponification value 0.135gNaOH / g) at 40°C with constant stirring, the total saponification of oil Quantity (147.2gNaOH); Weigh 144g sodium hydroxide (about 98% saponification), add 331ml deionized water (conductivity ≤ 1μs / cm) to prepare NaOH solution, wait until the temperature of NaOH solution drops to 40°C, slowly pour In the mixed oil, keep warm at 40°C and keep stirring to carry out saponification reaction.

[0050] After reacting for 5 hours, put it into the mold, cover it with a film to prevent water from evaporating, keep it warm in a 30°C incubator for 5-7 days, monitor the pH during the heat preservation period, take it out of the mold when the pH is 8-9, grind the soap block into mud, add Content 99.32% Niacinamide crystal 50g, fully knead and mix evenly, press into the mold to form, demould, the handmade soap after demoulding...

Embodiment 2

[0052] (1) Insulate 200g palm oil, 200g coconut oil and 600g corn oil (saponification value 0.136gNaOH / g) (total saponification amount is about 147.8g NaOH) at 40 ℃, keep stirring and mixing, weigh 140g sodium hydroxide (about 95% saponification), add 322ml of deionized water (conductivity ≤ 1μs / cm) to prepare NaOH solution, when the temperature of NaOH solution drops to 40°C, slowly pour it into the mixed oil, keep it warm at 40°C, and continue to stir for saponification reaction. Reaction 5hr;

[0053] (2) Enter the mold, cover it with a film to prevent water from evaporating, keep it warm in a 30°C incubator for 5-7 days, monitor the pH during the heat preservation period, and take it out for demoulding when the pH is 8-9;

[0054] (3) Grind the soap bar into mud, add 50g of nicotinamide crystals with a content of 99.32%, add 20 drops of lavender essential oil (about 1-1.2mL), knead and mix well;

[0055] (4) Press into a mold to form, demould, and the handmade soap after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com