A kind of preparation method of la-b containing high-strength and high-conductivity aluminum alloy and medium-thick plate

An aluminum alloy and high-conductivity technology, which is applied in the field of preparation of La-B-containing high-strength and high-conductivity aluminum alloys and their medium-thick plates, can solve problems such as hindering electron movement and reducing electrical conductivity, so as to reduce scattering, improve electrical conductivity, and ensure The effect of synchronous improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

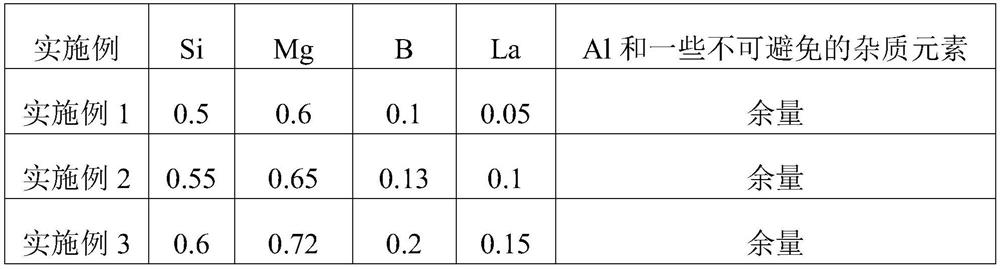

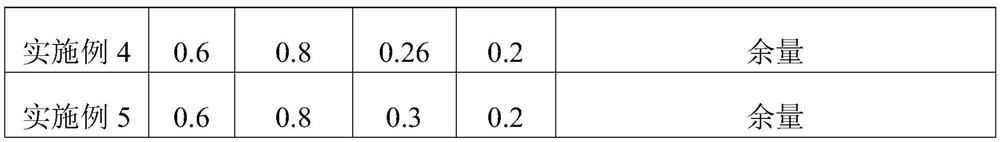

[0039] A preparation method for a high-strength and high-conductivity aluminum alloy plate containing La-B, the operation steps are as follows:

[0040] (1) Melting: use industrial-grade aluminum ingots with a purity of 99.85%, Al-La master alloy, Al B 3 The master alloy is used as the raw material, and the Al-La master alloy is added for purification treatment, and the AlB 3 The master alloy is subjected to boronization treatment, and the industrial grade aluminum ingot with a purity of 99.85% and elements other than the B element and the La element are mixed according to the corresponding weight percentages in Table 1, and then the Al-La master alloy is added for smelting to make the material Melting, smelting temperature is 760°C, heat preservation for 4 to 5 hours, to obtain molten aluminum;

[0041] (2) Purification, degassing and filtration: the temperature of the molten aluminum obtained in step (1) is kept at 760°C, after the Al-La master alloy is completely melted, k...

Embodiment 2

[0051] A preparation method for a high-strength and high-conductivity aluminum alloy plate containing La-B, the operation steps are as follows:

[0052] (1) Melting: use industrial-grade aluminum ingots with a purity of 99.85%, Al-La master alloy, Al B 3 The master alloy is used as the raw material, and the Al-La master alloy is added for purification treatment, and the AlB 3 The master alloy is subjected to boronization treatment, and the industrial grade aluminum ingot with a purity of 99.85% and elements other than the B element and the La element are mixed according to the corresponding weight percentages in Table 1, and then the Al-La master alloy is added for smelting to make the material Melting, smelting temperature is 770°C, heat preservation for 3-4 hours, to get molten aluminum;

[0053] (2) Purification, degassing and filtration: the temperature of the aluminum liquid obtained in step (1) is kept at 770°C, after the Al-La master alloy is completely melted, keep it...

Embodiment 3

[0063] A preparation method for a high-strength and high-conductivity aluminum alloy plate containing La-B, the operation steps are as follows:

[0064] (1) Melting: use industrial-grade aluminum ingots with a purity of 99.85%, Al-La master alloy, Al B 3 The master alloy is used as the raw material, and the Al-La master alloy is added for purification treatment, and the AlB 3 The master alloy is subjected to boronization treatment, and the industrial grade aluminum ingot with a purity of 99.85% and elements other than the B element and the La element are mixed according to the corresponding weight percentages in Table 1, and then the Al-La master alloy is added for smelting to make the material Melting, smelting temperature is 770°C, heat preservation for 3-4 hours, to get molten aluminum;

[0065] (2) Purification, degassing and filtration: the temperature of the aluminum liquid obtained in step (1) is kept at 770°C, after the Al-La master alloy is completely melted, keep it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com