Microsphere Coating System

A coating system and microsphere technology, applied in coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of uneven coating and inconvenient replacement of quartz discs, and achieve uniform coating and rotating path. Rich, easy to install and use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

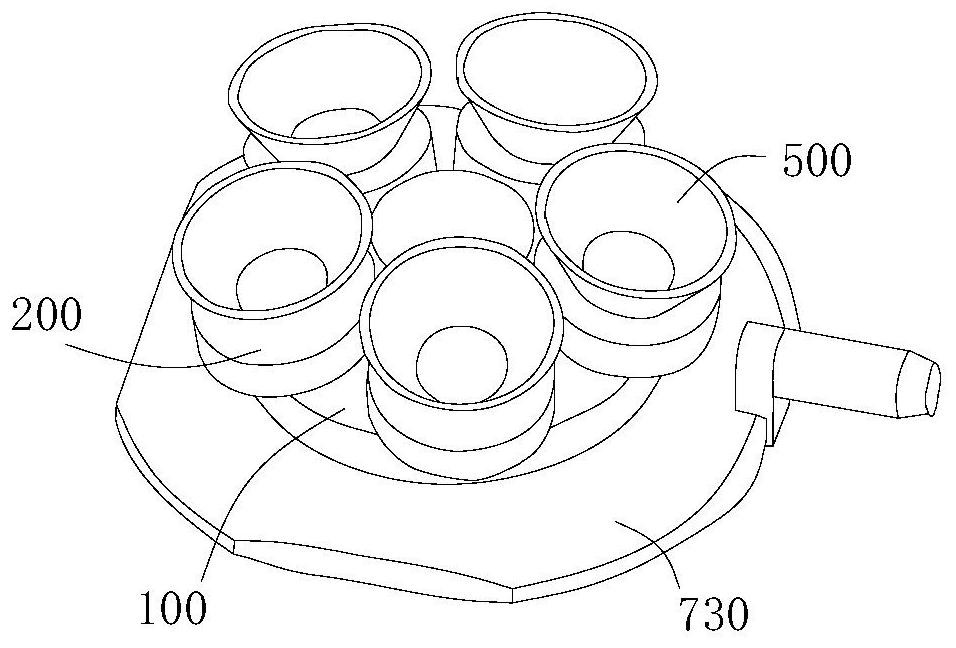

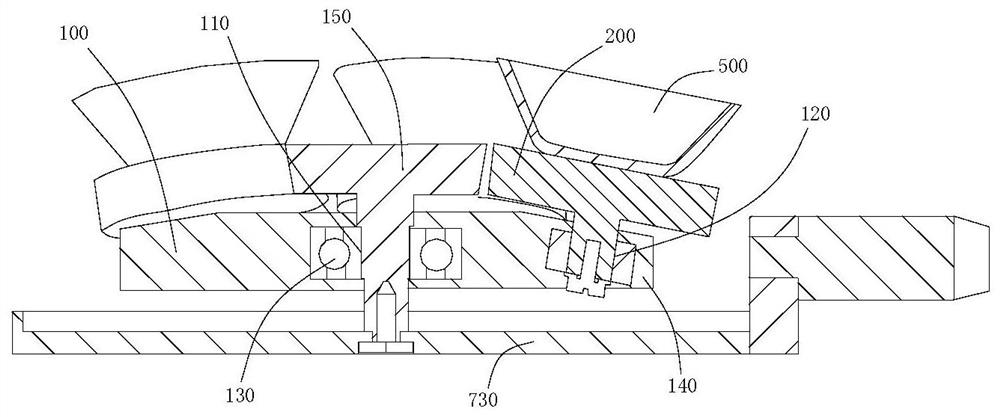

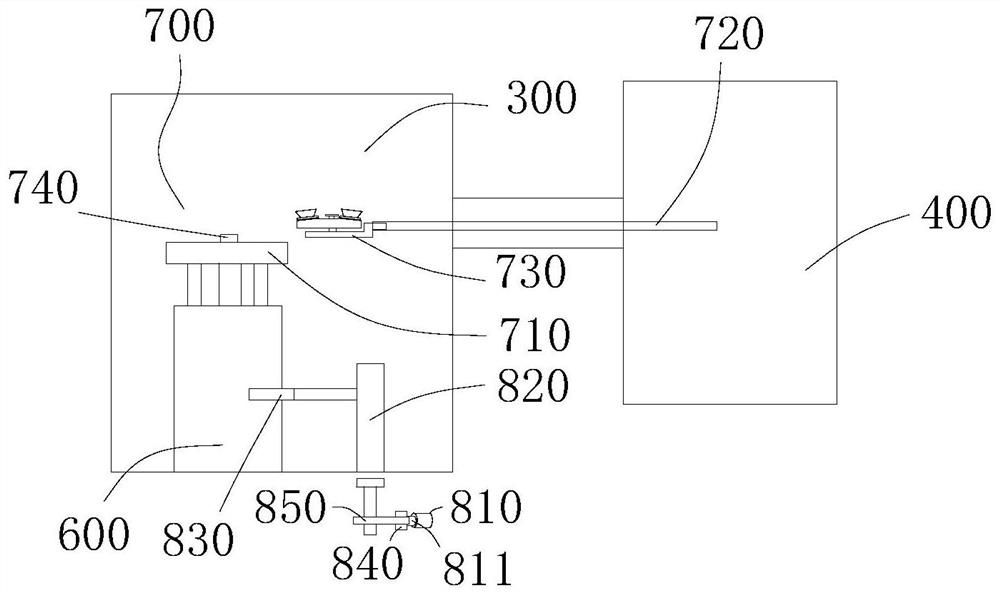

[0046] see figure 1 - figure 2 , the present embodiment provides a rebound disc device, which includes:

[0047] Rotary disk 100,

[0048] An autorotation disk 200 , the autorotation disk 200 is installed on the revolution disk 100 , the rotation axis of the rotation disk 200 is set eccentrically with the central axis of the revolution disk 100 , and the rotation disk 200 is used for installing the quartz disk 500 .

[0049] In the rebounding disk device provided in this embodiment, the revolving disk 100 is provided with an eccentric autorotating disk 200. During use, the quartz disk 500 is placed on the rotating disk 200, and the revolving disk 100 drives the rotating disk 200 to rotate during the rotation process. When the turntable 200 rotates with the revolving disk 100, it rotates by itself and drives the quartz disk 500 to rotate. With such a structural design, the rotation paths of the microspheres in the quartz disk 500 are more abundant and more random, making the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com