A method for suppressing polycrystallization of single crystal diamond edges

A single-crystal diamond and diamond technology, which is applied in the field of single-crystal diamond preparation to achieve the effects of reducing the height of vertical growth, suppressing the speed of lateral epitaxy, and improving the quality of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

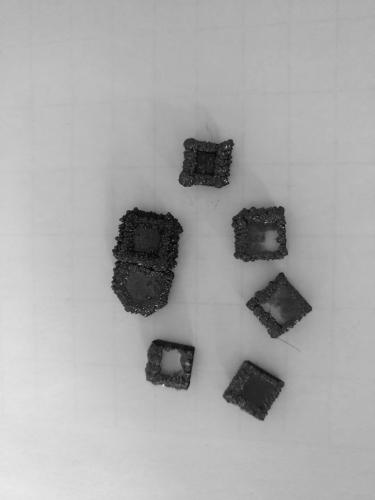

Image

Examples

Embodiment 1

[0036] The method for suppressing polycrystallization of single crystal diamond edge of the present embodiment, comprises the following steps:

[0037] 1) Preparation and selection of substrate

[0038] The single crystal was diced to obtain several substrates with a (100) orientation and a thickness of 350 μm.

[0039] 2) Pretreatment of the substrate

[0040] The substrate in step 1) is treated with aqua regia, acetone and alcohol ultrasonic cleaning, the number of cleanings for each cleaning medium is 3 times, and the cleaning time is 3 minutes each time, and then select the side with better quality and no impurities and defects as a growth surface.

[0041] 3) Crystal growth

[0042] ① Open the chamber of the MPCVD equipment, and place the substrate processed in step 2) on the surface of the heat sink of the molybdenum abutment, and place it in a square or circular shape based on the center of the abutment; vacuumize to 1 ×10 -3 Below Pa, pass into H 2 , H 2 The flo...

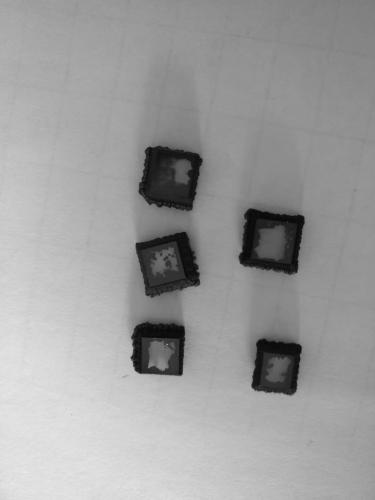

Embodiment 2

[0046] The method for suppressing polycrystallization of single crystal diamond edge of the present embodiment, comprises the following steps:

[0047] 1) Preparation and selection of substrate

[0048] The single crystal was diced to obtain several substrates with a (100) orientation and a thickness of 350 μm.

[0049] 2) Pretreatment of the substrate

[0050] The substrate in step 1) is treated with aqua regia, acetone and alcohol ultrasonic cleaning, the number of cleanings for each cleaning medium is 3 times, and the cleaning time is 3 minutes each time, and then select the side with better quality and no impurities and defects As a growing surface, clean the growing surface and edges with a dust-free swab.

[0051] 3) Crystal growth

[0052] ① Open the chamber of the MPCVD equipment, and place the substrate processed in step 2) on the surface of the heat sink of the molybdenum abutment, and place it in a square or circular shape based on the center of the abutment; vac...

Embodiment 3

[0056] The method for suppressing polycrystallization of single crystal diamond edge of the present embodiment, comprises the following steps:

[0057] 1) Preparation and selection of substrate

[0058] The single crystal was diced to obtain several substrates with a (100) orientation and a thickness of 350 μm.

[0059] 2) Pretreatment of the substrate

[0060] The substrate in step 1) is treated with aqua regia, acetone and alcohol ultrasonically cleaned. The number of cleanings for each cleaning medium is 3 times, and the time for each cleaning is 3 minutes. Then select the side with better quality and no impurities and defects. As a growing surface, clean the growing surface and edges with a dust-free swab.

[0061] 3) Crystal growth

[0062] ① Open the chamber of the MPCVD equipment, and place the substrate processed in step 2) on the surface of the heat sink of the molybdenum abutment, and place it in a square or circular shape based on the center of the abutment; vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com