High-tensile piezoelectric microfiber with two-stage wave structure and manufacturing method thereof

A wavy structure, microfiber technology, applied in fiber processing, yarn, filament/wire forming, etc., can solve the problem of increasing the inhomogeneity of the mechanical properties of the sensor, not solving the pre-stretching strain and large deformation ability of piezoelectric microfibers, unfavorable Practical application and other issues, to achieve the effects of large-scale preparation, improvement of structural designability, tensile properties, and high deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

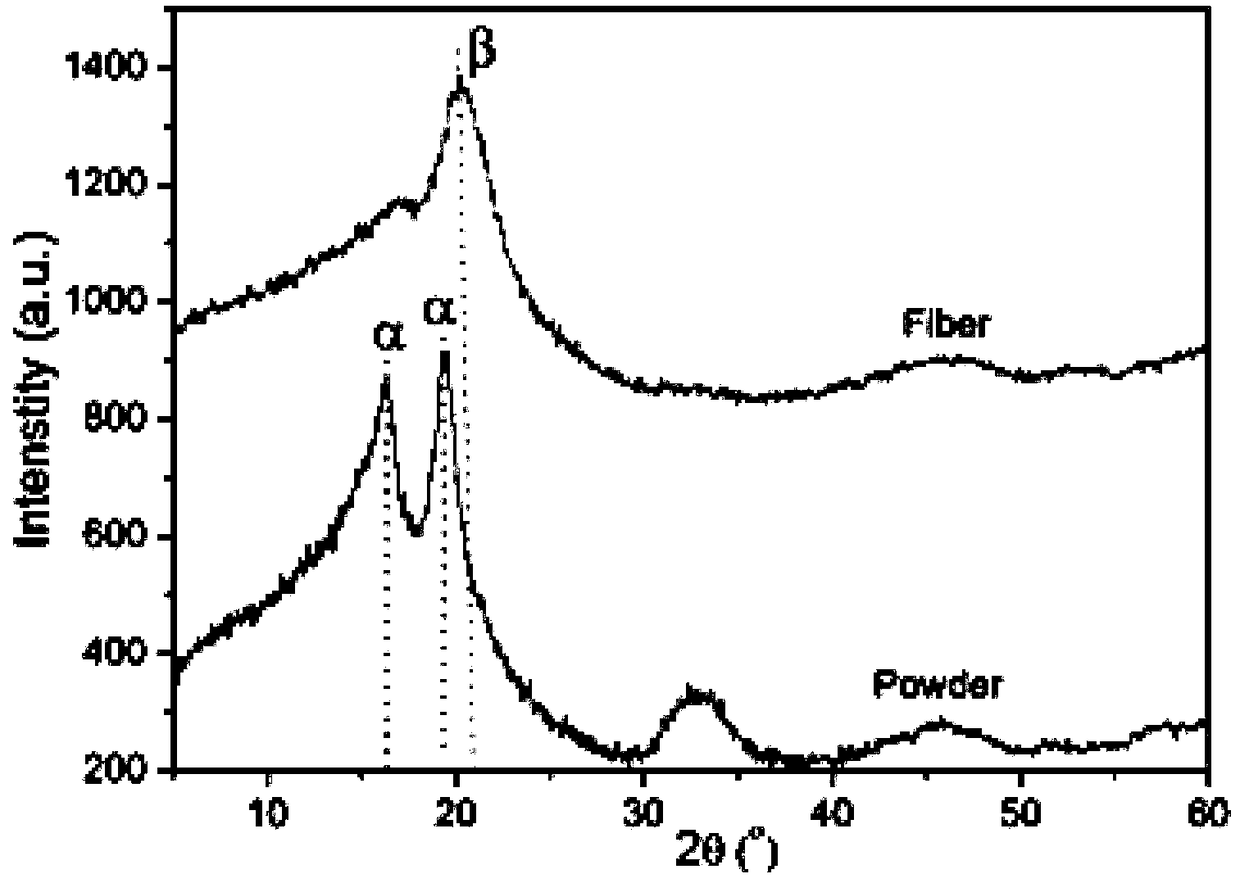

[0036] A kind of PVDF high tensile piezoelectric microfiber with two-stage wave structure, its preparation method comprises the steps:

[0037] 1) Prepare PVDF electrospinning solution.

[0038] Weigh 1g of PVDF powder, put it into a 25mL sample bottle with a stirring magnet, then add 2.5g of DMF and 2.5g of acetone, and quickly cover the bottle to prevent the acetone from volatilizing. Place the sample bottle on a magnetic stirrer to stir, set the heating temperature to 35°C, and stir for 4-6h until a uniform and transparent PVDF electrospinning solution is obtained. The spinning solution was left to stand for half an hour to remove air bubbles and set aside.

[0039] 2) Preparation of in-plane wavy PVDF piezoelectric microfibers.

[0040] Use a 1mL syringe to draw the PVDF solution after standing, connect the positive pole of the high-voltage DC power supply to the needle of the syringe, connect the negative pole of the high-voltage power supply to the metal collection pla...

Embodiment 2

[0048] A kind of PVDF high tensile piezoelectric microfiber with two-stage wave structure, its preparation method comprises the steps:

[0049] 1) Prepare PVDF electrospinning solution.

[0050] Weigh 1g of PVDF powder, put it into a 25mL sample bottle with a stirring magnet, then add 2g of DMF and 2g of acetone, and quickly cover the bottle to prevent the acetone from volatilizing. Place the sample bottle on a magnetic stirrer to stir, set the heating temperature to 35°C, and stir for 4-6h until a uniform and transparent PVDF electrospinning solution is obtained. The spinning solution was left to stand for half an hour to remove air bubbles and set aside.

[0051] 2) Preparation of in-plane wavy PVDF piezoelectric microfibers with different amplitude-wavelength ratios.

[0052] Use a 1mL syringe to draw the PVDF solution after standing, connect the positive pole of the high-voltage DC power supply to the needle of the syringe, connect the negative pole of the high-voltage D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com