A Fast and Simple Method for Molecular Weight Fractionation of Humic Acid

A grading method, humic acid technology, applied in chemical instruments and methods, color/spectral characteristic measurement, other chemical processes, etc., can solve the problems of high requirements for instruments and equipment, long time-consuming grading, difficult to obtain, etc., and meet the requirements of experimental equipment Effects of low, improved classification efficiency, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

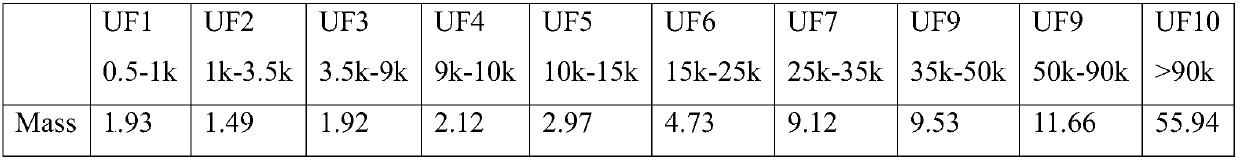

Embodiment 1

[0036] A method for grading the molecular weight of humic acid, comprising the steps of:

[0037] S1. Put 40mg of nanometer iron ferric oxide into 500-1000Da, 3500Da, 9000Da, 10000Da, 15000Da, 25000Da, 35000Da, 50000Da, 90000Da 9 molecular weight grade regenerated cellulose membranes respectively, and wrap both ends of the membrane with membrane Clamp and clamp to make 9 film packs with different molecular weight grades;

[0038]S2. Add 50mg of humic acid into a 500ml volumetric flask, add 1M NaOH solution dropwise therein until the humic acid is completely dissolved, set the volume to 500ml with deionized water, adjust the humic acid with concentrated hydrochloric acid of 39% by mass The pH of the solution was 5.0, and the membrane bag with the smallest molecular weight grade was added thereto, and stirred at 120 rip / min at 20-25° C. for 1 h in stages.

[0039] S3. After the film bag adsorption reaction is completed, take out the film bag, and measure the concentration of th...

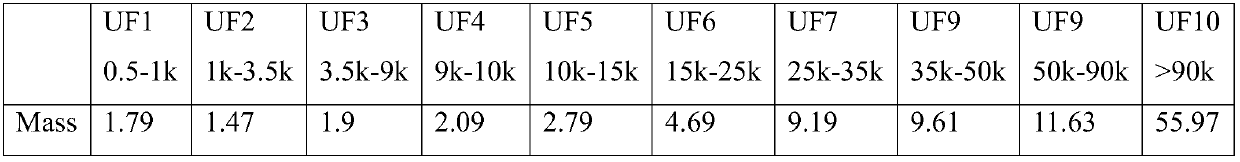

Embodiment 2

[0050] A humic acid molecular weight classification method, comprising the steps of:

[0051] S1. Put 60mg of nanometer iron ferric oxide into 500-1000Da, 3500Da, 9000Da, 10000Da, 15000Da, 25000Da, 35000Da, 50000Da, 90000Da 9 molecular weight grades of regenerated cellulose film respectively, and wrap both ends of the film with film Clamp and clamp to make 9 film packs with different molecular weight grades;

[0052] S2. Add 50mg of humic acid into a 500ml volumetric flask, add 1M NaOH solution dropwise therein until the humic acid is completely dissolved, set the volume to 500ml with deionized water, adjust the humic acid with concentrated hydrochloric acid of 39% by mass The pH of the solution is 5.0, add the membrane bag with the smallest molecular weight grade to it, and stir in stages at 120rip / min at 20-25°C for 0.5h;

[0053] S3. After the film bag adsorption reaction is completed, take out the film bag, and measure the concentration of the humic acid solution outside ...

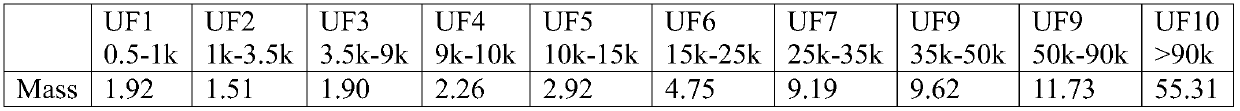

Embodiment 3

[0064] A humic acid molecular weight classification method, comprising the steps of:

[0065] S1. Put 60mg of nanometer iron ferric oxide into 500-1000Da, 3500Da, 9000Da, 10000Da, 15000Da, 25000Da, 35000Da, 50000Da, 90000Da 9 molecular weight grades of regenerated cellulose film respectively, and wrap both ends of the film with film Clamp and clamp to make 9 film packs with different molecular weight grades;

[0066] S2. Add 80mg of humic acid in a 500ml volumetric flask, add 1M NaOH solution dropwise therein until the humic acid is completely dissolved, set the volume to 500ml with deionized water, and adjust the humic acid with concentrated hydrochloric acid of 39% by mass The pH of the solution was 5.0, and the membrane bag with the smallest molecular weight grade was added thereto, and stirred at 120 rip / min at 20-25° C. for 1 h in stages.

[0067] S3. After the film bag adsorption reaction is completed, take out the film bag, and measure the concentration of the humic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com