Simulation calculation method of monolayer graphene material peeled off by dispersed carbon nanotubes

A technology of single-layer graphene and carbon nanotubes, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as labor-intensive, fibrous one-dimensional material entanglement, process parameter changes, etc., to achieve The effect of reducing the cost of manpower and material resources, simplifying the determination process, and stabilizing the production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

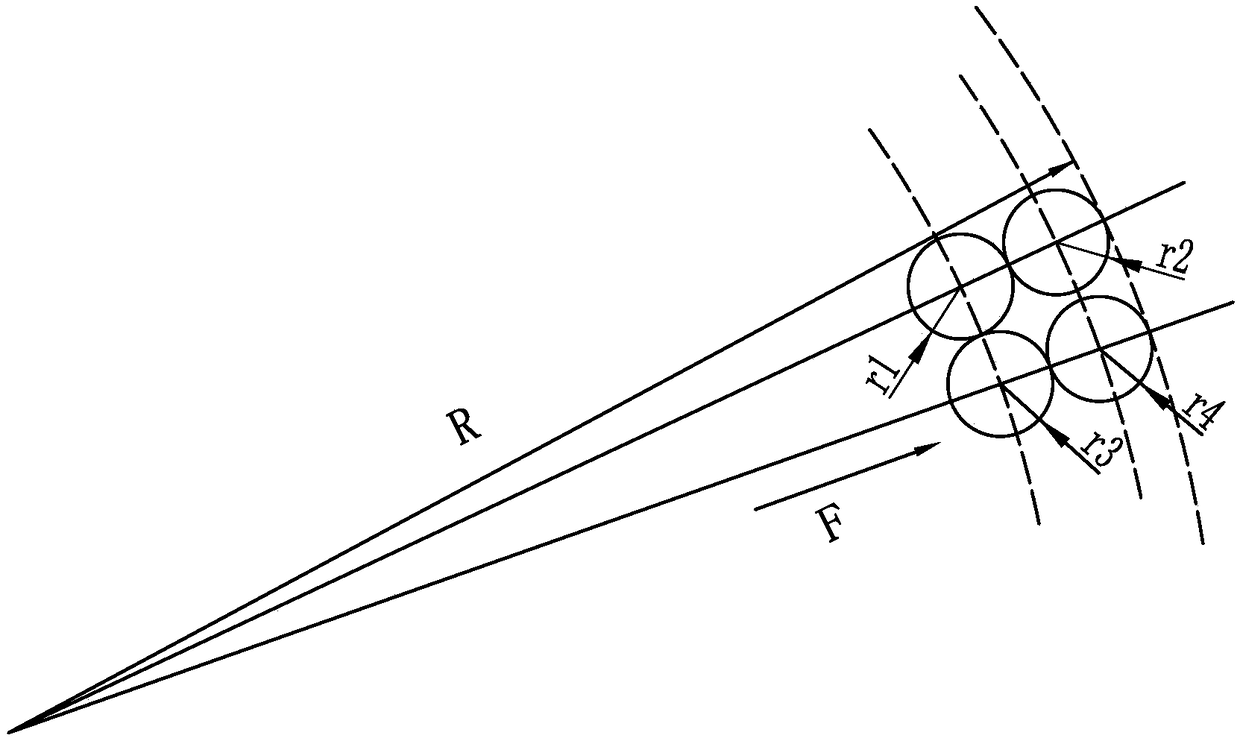

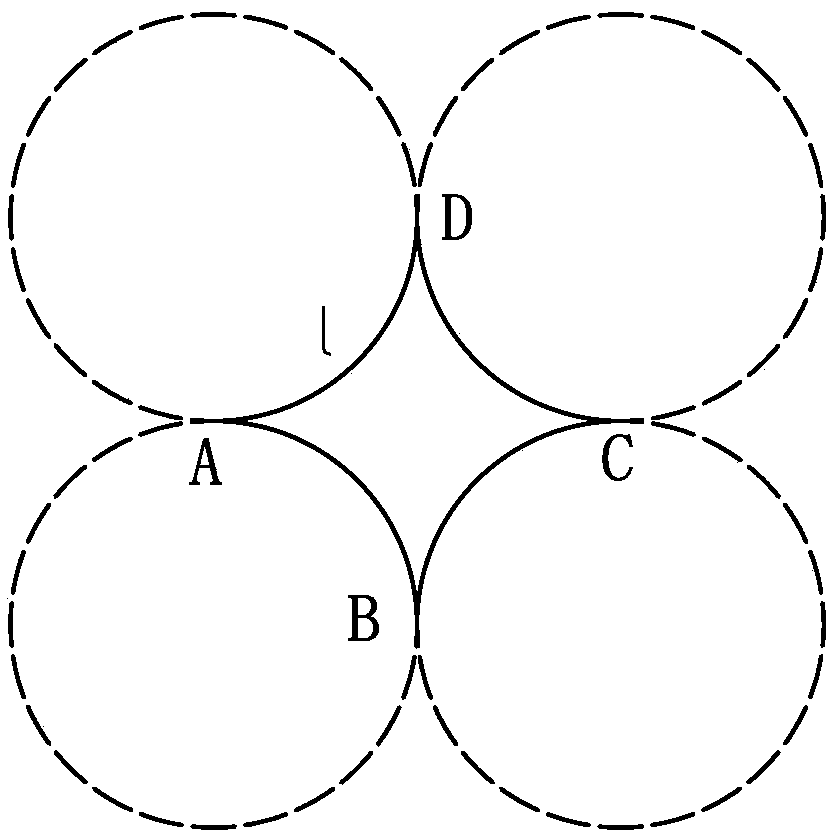

[0042] Such as Figure 1 ~ Figure 2 Shown, the simulation calculation method of the dispersed carbon nanotube of the present invention described in the present invention exfoliates single-layer graphene material, comprises the following steps:

[0043] Step 1: Establish a mathematical model based on the high-speed centrifugal movement of the grinding balls in the grinding chamber, and the trajectory of the balls colliding with each other, friction and shearing;

[0044] Step 2: According to the model calculation, the centrifugal friction shear strength

[0045] where m 总 is the total mass of the ball, v is the linear velocity of the ball when it moves centrifugally, R is the radius of the grinding chamber, and r is the radius of the ball.

[0046] It also includes step 3: deduce the blind zone between the balls according to the model, that is, the dispersion limit length of the dispersion limit zone

[0047]Calculation in step 3 shows that the dispersion limit length of...

Embodiment 2

[0070] Such as image 3 As shown, take 10.6kg of carbon nanotube powder, 2.67kg of dispersant and 200kg of solvent. The solvent is nitrogen methyl pyrrolidone NMP. In the grinding equipment, the inner cavity of the 30L grinding equipment is 244mm in diameter. Usually, those skilled in the art know that the grinding equipment adopts the continuous grinding method for grinding. Ground material. 50kg, 1.4μm balls were used to grind and disperse at a high speed for 6 hours at a linear speed of 11m / s to form a viscous carbon nanotube dispersion. Afterwards, the carbon nanotube dispersion was coated on an aluminum foil and dried for scanning electron microscope (SEM) analysis.

[0071] Depend on image 3 It can be seen that the carbon nanotube powder is composed of agglomerates of micro-nano balls of several microns to more than 10 microns. After dispersion by 1.4μm beads, if Figure 4 As shown in the SEM image of carbon nanotubes dispersed by 1.4 μm beads, the carbon nanotubes...

Embodiment 3

[0074] The diameter of the grinding ball is 1.0 μm, and the rest are the same as in Example 2. Viscous carbon nanotube dispersion is formed after grinding, such as Figure 5 shown.

[0075] Such as Figure 5 As shown, the micro-nano aggregates of carbon nanotube powder are completely opened, and the carbon tubes are uniformly dispersed. according to Calculation, the frictional shear strength between the balls ∑P=258.9GPa, which is less than the limit threshold of frictional shear 650.14GPa, the carbon nanotubes will not be sheared and torn off, and the experimental Figure 5 The results of SEM images of carbon nanotubes dispersed with 1.0 μm beads are consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap