A facility cultivation method for stropharia stropharia and cowpea rotation

A cultivation method and a technology for the mushroom, which are applied in the field of facility cultivation of the rotation of the mushroom and cowpea, and can solve the problems that restrict the promotion and commercial production of the mushroom, the degree of decay is difficult to control, and it is difficult to grow offspring. physical and other problems, to achieve the effect of promoting the reproduction of beneficial microorganisms, shortening the cultivation period, and increasing the species and quantity of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

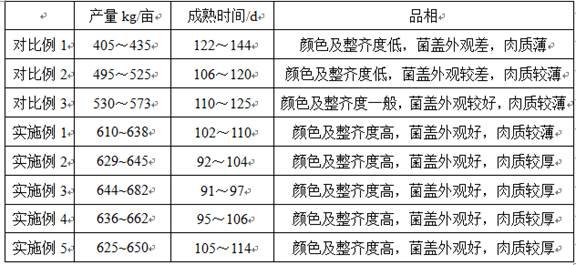

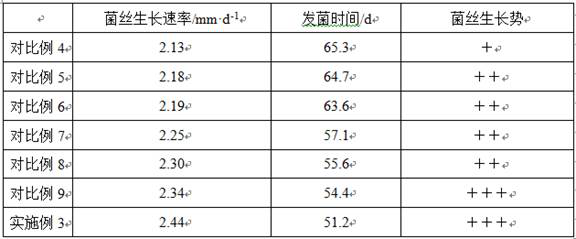

Examples

Embodiment 1

[0041] A facility culture method for crop rotation of stropharia stropharia and cowpea, comprising the following steps:

[0042] S1. Compost fermentation: Corn stalks, corn cobs, and rice husks are composted and fermented separately as compost components; every 100 parts of compost consists of the following components by mass: 40 parts of corn stalks, 30 parts of corn cobs, and rice husks 30 copies;

[0043] S2. Building a mushroom shed: Choose a flat terrain, sufficient and stable water source, sandy soil, neutral or alkaline cowpea field, deep plow the harvested cowpea field, turn the cowpea straw into the ground, and keep it at 7~ 10d, then build a greenhouse on it, using 6*Φ25 hot-dip galvanized steel pipes to build a greenhouse with a height of 3m, a width of 8m, a length of 40m, and a side rail interval of 1m, and cover it with a layer of plastic film and 2 layers of 8-pin shade From the net to the bottom of the shed, the two sides of the shed are clamped with slots, th...

Embodiment 2

[0061] A facility culture method for crop rotation of stropharia stropharia and cowpea, comprising the following steps:

[0062] S1. Compost fermentation: Sesame stalks, corn cobs, and rice husks are composted and fermented separately as compost components; every 100 parts of compost consists of the following components by mass: 45 parts of sesame straw, 27.5 parts of corn cobs, rice husk 27.5 copies;

[0063] S2. Building a mushroom shed: Choose a flat terrain, sufficient and stable water source, sandy soil, neutral or alkaline cowpea field, deep plow the harvested cowpea field, turn the cowpea straw into the ground, and keep it at 7~ 10d, then build a greenhouse on it, use cement pipes to build a greenhouse with a height of 3m, a width of 8m, a length of 40m, and a side rail interval of 1m, and cover a layer of plastic film and 2 layers of 8-pin shade nets to the bottom of the shed. Clamp it tightly with a card slot, compact the soil around the bottom of the shed, and insta...

Embodiment 3

[0071] A facility culture method for crop rotation of stropharia stropharia and cowpea, comprising the following steps:

[0072] S1. Compost fermentation: rice straw, corn cob, and rice husk are composted and fermented separately as compost components; every 100 parts of compost consists of the following components by mass: 50 parts of rice straw, 25 parts of corn cob, and rice husk 25 copies;

[0073] S2. Building a mushroom shed: choose a flat terrain, sufficient and stable water source, sandy soil, neutral or slightly alkaline cowpea field, deep plow the harvested cowpea field, turn the cowpea straw into the ground, and keep it at 7~ 10d, then build a greenhouse on it, using 6*Φ25 hot-dip galvanized steel pipes to build a greenhouse with a height of 3m, a width of 8m, a length of 40m, and a side rail interval of 1m, and cover it with a layer of plastic film and 2 layers of 8-pin shade From the net to the bottom of the shed, the two sides of the shed are clamped with slots,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com