A paper-based gypsum board with high strength and low absorption

A low-absorption, gypsum board technology, applied in paper/cardboard layered products, papermaking, textiles and papermaking, etc., can solve problems affecting the normal use and aesthetics of paper-faced gypsum board walls, and the decrease in flexural strength and impact strength. , plate strength reduction and other problems, to achieve the effect of facilitating secondary modification treatment, increasing strength, and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

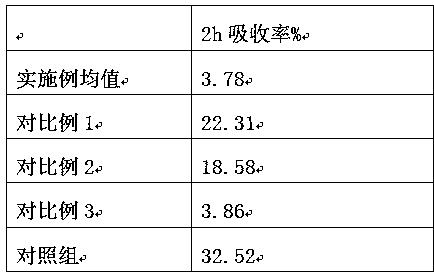

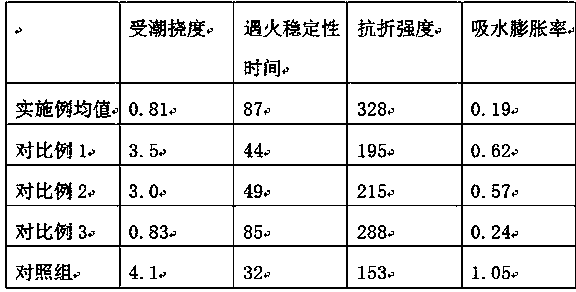

Examples

Embodiment 1

[0020] A high-strength and low-absorbency paper gypsum board, which is made of a composite of an intermediate base layer and an outer face-protecting paper, the intermediate base layer is a gypsum board layer; the face-protecting paper is made of the following components in parts by weight Components: waste newspaper 80, fiber modified bentonite 25, cellulase 0.15, calcium carbonate 3.7, water 95.

[0021] Further, the preparation method of the fiber modified bentonite is:

[0022] (1) Stir and soak the bentonite with 5.5% sodium hydroxide solution at 40°C for 30 minutes, then add dropwise nitric acid solution with a mass fraction of 6%, until the pH of the mixed system reaches neutral, and then carry out Suction filtration, drying;

[0023] (2) Soak the glass fibers in a 10% sodium hydroxide solution at 64°C for 1 hour, then filter, wash with deionized water, and dry to constant weight;

[0024] (3) Put the bentonite after the above treatment into the cetyltrimethylammonium...

Embodiment 2

[0034] A high-strength and low-absorbency paper gypsum board, which is made by compounding an intermediate base layer and an outer face-protecting paper, the intermediate base layer is a gypsum board layer; the face-protecting paper is made of the following components in parts by weight Composition: waste newspaper 85, fiber modified bentonite 28, cellulase 0.19, calcium carbonate 4.2, water 98.

[0035] Further, the preparation method of the fiber modified bentonite is:

[0036] (1) Stir and soak the bentonite with 5.5% sodium hydroxide solution at 40°C for 30 minutes, then add dropwise nitric acid solution with a mass fraction of 6%, until the pH of the mixed system reaches neutral, and then carry out Suction filtration, drying;

[0037] (2) Soak the glass fibers in 10% sodium hydroxide solution at 64°C for 1 hour, then filter, wash with deionized water, and dry to constant weight;

[0038] (3) Put the bentonite after the above treatment into the cetyltrimethylammonium bro...

Embodiment 3

[0048] A high-strength and low-absorbency paper gypsum board, which is made of a composite of an intermediate base layer and an outer face-protecting paper, the intermediate base layer is a gypsum board layer; the face-protecting paper is made of the following components in parts by weight Composition: waste newspaper 82, fiber modified bentonite 26, cellulase 0.17, calcium carbonate 3.9, water 97.

[0049] Further, the preparation method of the fiber modified bentonite is:

[0050] (1) Stir and soak the bentonite with 5.5% sodium hydroxide solution at 40°C for 30 minutes, then add dropwise nitric acid solution with a mass fraction of 6%, until the pH of the mixed system reaches neutral, and then carry out Suction filtration, drying;

[0051] (2) Soak the glass fibers in a 10% sodium hydroxide solution at 64°C for 1 hour, then filter, wash with deionized water, and dry to constant weight;

[0052] (3) Put the bentonite after the above treatment into the cetyltrimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com