A simple forging wheel frame of a transporting truck

The technology of a truck and a wheel frame is applied in the field of parts of the truck, which can solve the problems of non-compliance with environmental protection requirements, high cost, high work intensity, etc., and achieve the effects of avoiding environmental protection three wastes, simple and easy manufacturing process, and reducing work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

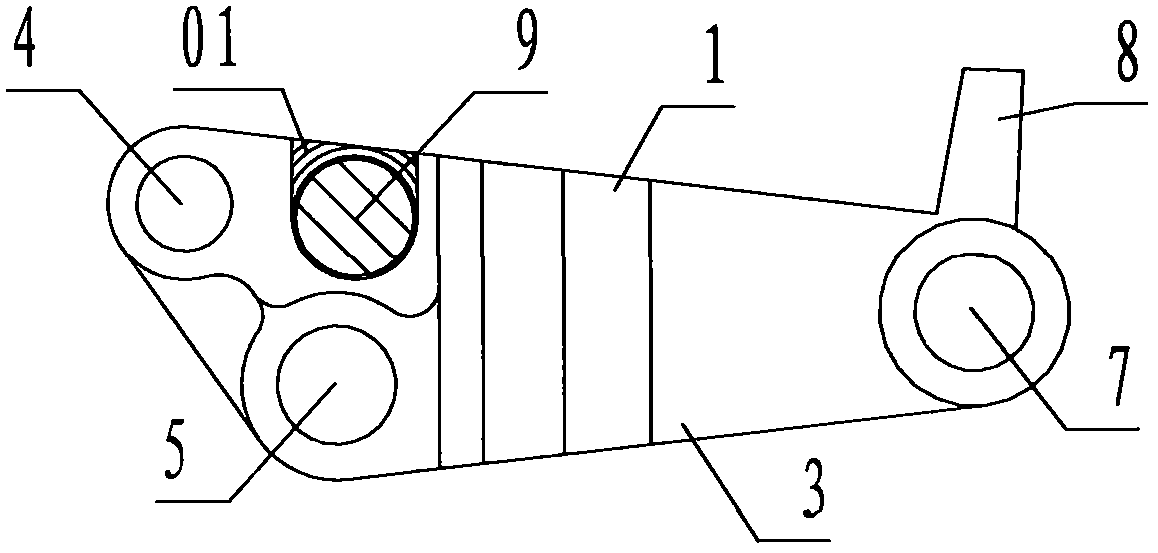

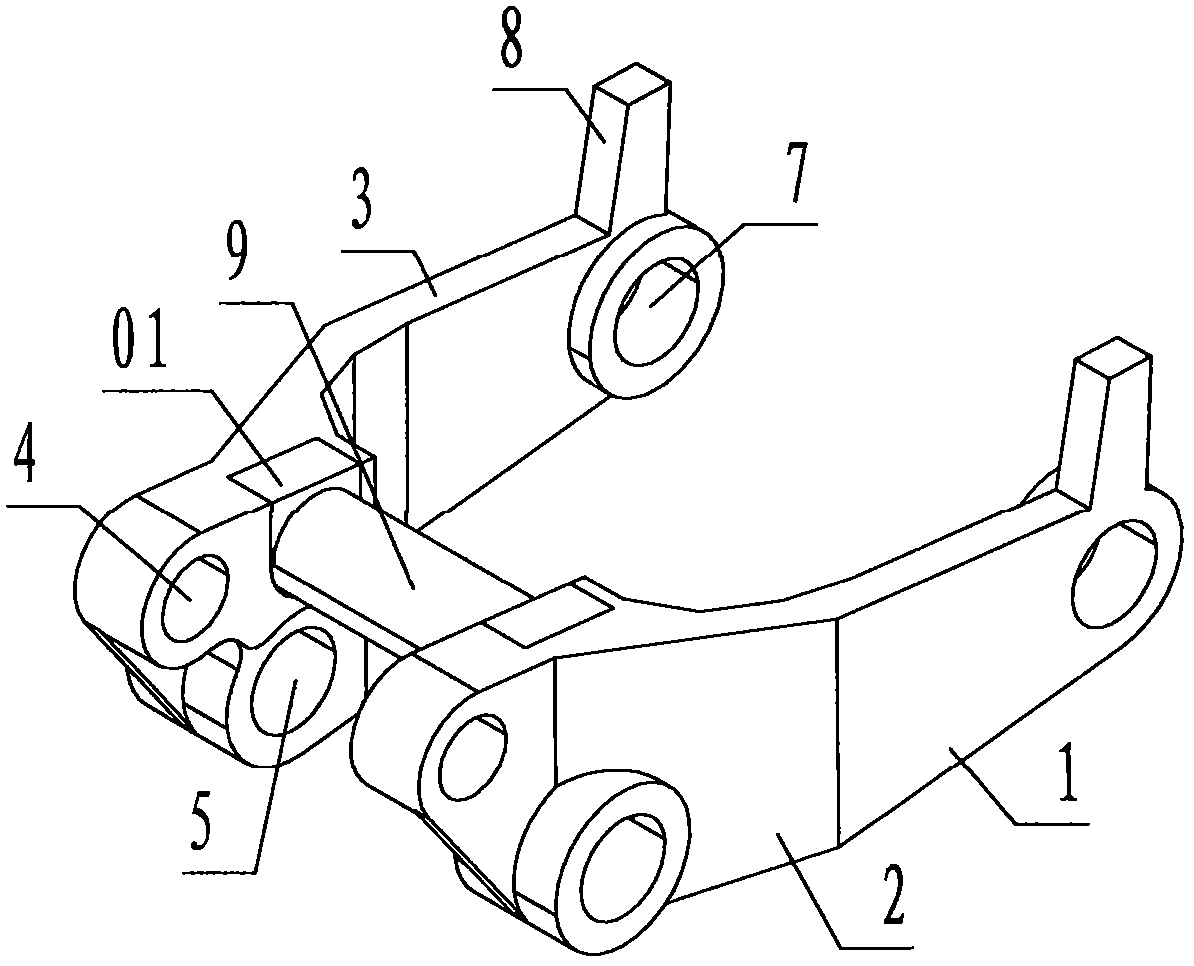

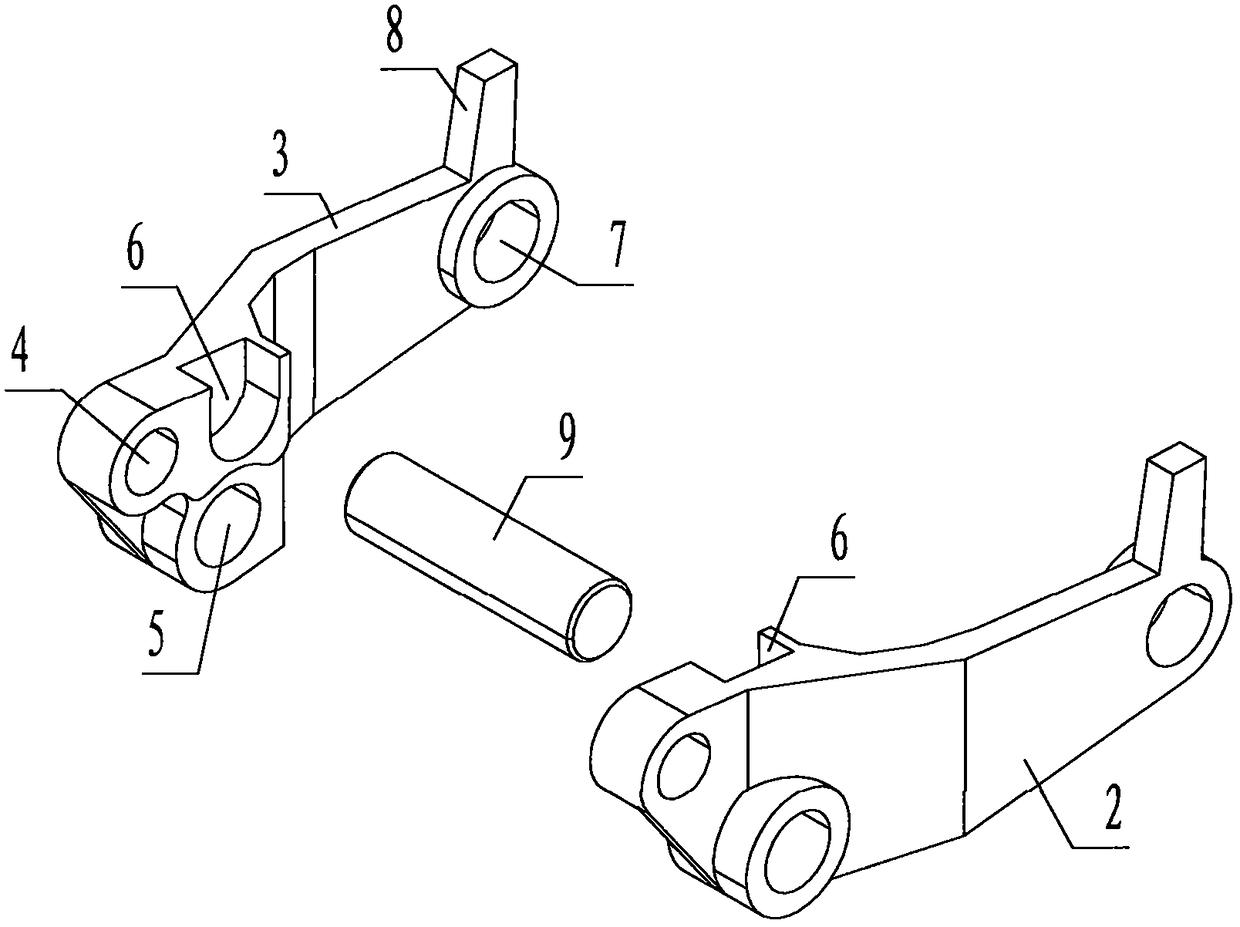

[0021] refer to Figure 1 ~ Figure 3 , a simple forged wheel frame for a transport vehicle of the present invention, referred to as the wheel frame 1, includes a front side block 2, a rear side block 3 and a connecting rod 9, wherein: the rear side block 3 is in the shape of a triangular block in the main view projection The upper left part of the rear side block 3 is provided with a circular through hole in the front and rear direction, which is called the upper left shaft hole 4; the lower left part of the rear side block 3 is provided with a circular through hole in the front and rear direction, which is called the lower left shaft hole 5 The right part of the rear side block 3 is provided with a circular through hole in the front and rear direction and is called the right shaft hole 7; the front of the rear side block 3, on the right side of the upper left shaft hole 4, is also provided with a top open The groove is called the connecting groove 6; on the upper right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com