A quantum transmission type high-performance thin film sensing material and a preparation method thereof

A transmission-type, high-performance technology, which is applied in the fields of analysis of materials, metal material coating process, and material analysis by electromagnetic means. Facilitate integration and reduce material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

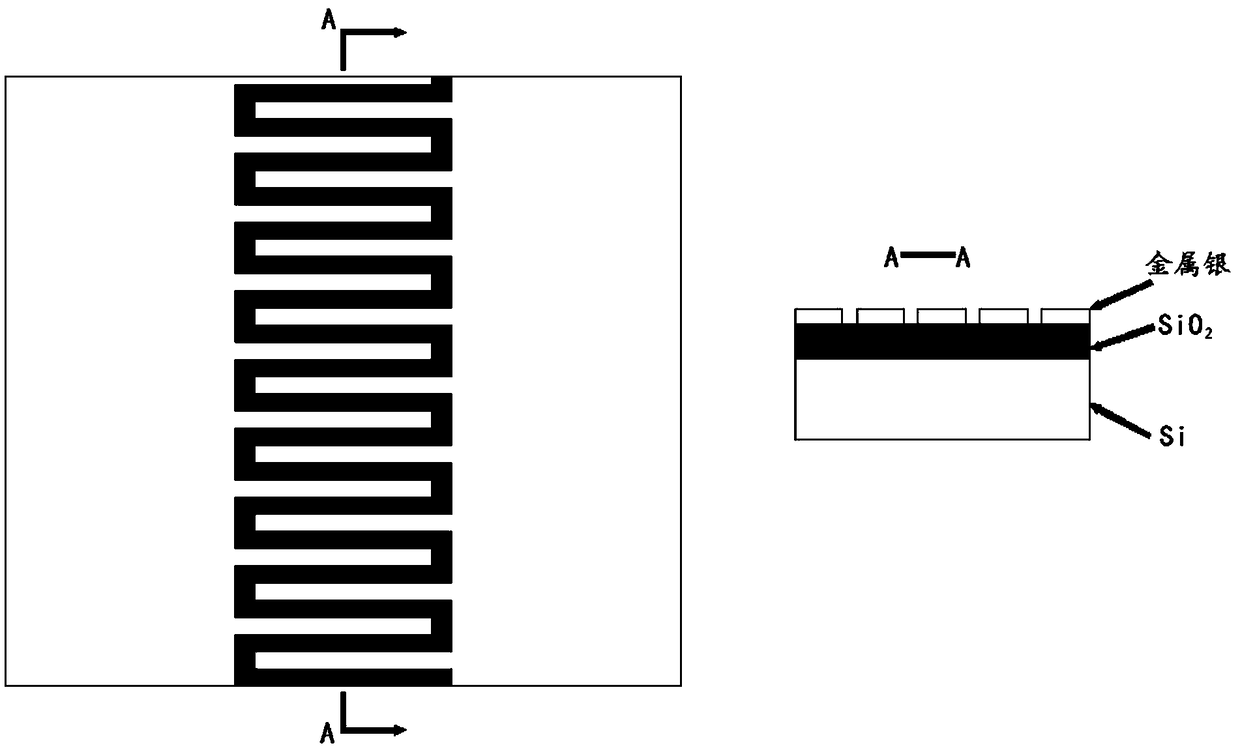

[0023] A quantum transmission-type high-performance thin-film sensing material, including the following raw materials in proportions by weight: 20 grams of interdigitated electrodes, 50 grams of monocrystalline silicon wafers, 10 grams of SiO2 insulating layers, 20 grams of metal films, and 50 grams of Pd nanoparticles , 60 grams of PMMA protective layer, 50 grams of Cr nanoparticles, 50 grams of Ni nanoparticles, 50 grams of AI nanoparticles, 100 grams of PET plastics and 50 grams of Pd-Ni alloy nanoparticles.

[0024] Quantum transmission type high-performance thin-film sensing materials are divided into quantum conductance nano-film sensing materials and quantum conductance mechanical thin-film sensing materials. formed by the array.

[0025] Another technical problem to be solved by the present invention is to provide a method for preparing a quantum transmission type high-performance thin-film sensing material, which includes the following steps:

[0026] 1) Processing of ...

Embodiment 2

[0030] A quantum transmission type high-performance thin-film sensing material, including the following raw materials in proportion by weight: 30 grams of interdigitated electrodes, 70 grams of monocrystalline silicon wafers, 15 grams of SiO2 insulating layers, 30 grams of metal films, and 75 grams of Pd nanoparticles , 70 grams of PMMA protective layer, 75 grams of Cr nanoparticles, 75 grams of Ni nanoparticles, 75 grams of AI nanoparticles, 110 grams of PET plastics and 75 grams of Pd-Ni alloy nanoparticles.

[0031] Except for the above differences, other aspects of the second embodiment are the same as those of the first embodiment, and the second embodiment also has the same advantages as those of the first embodiment, which will not be repeated here.

Embodiment 3

[0033] A quantum transmission type high-performance thin-film sensing material, including the following raw materials in proportion by weight: 50 grams of interdigitated electrodes, 90 grams of monocrystalline silicon wafers, 30 grams of SiO2 insulating layers, 40 grams of metal films, and 100 grams of Pd nanoparticles , 80 grams of PMMA protective layer, 100 grams of Cr nanoparticles, 100 grams of Ni nanoparticles, 100 grams of AI nanoparticles, 120 grams of PET plastics and 100 grams of Pd-Ni alloy nanoparticles.

[0034] Except for the above differences, the third embodiment is the same as the first embodiment above, and the third embodiment also has the same advantages as the first embodiment above, which will not be repeated here.

[0035] The beneficial effects of the present invention are: the cluster beam deposition technology is the current mainstream technology for gas-phase preparation of nanoparticle-assembled thin films, and has the advantages of high compatibility...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com