Preparation method of Cr-doped alpha-Fe2O3 micro-nano crystal

A micro-nano, reaction technology, applied in nanotechnology, iron oxide, iron oxide/iron hydroxide and other directions, can solve problems such as no literature reports, and achieve the effects of excellent performance, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

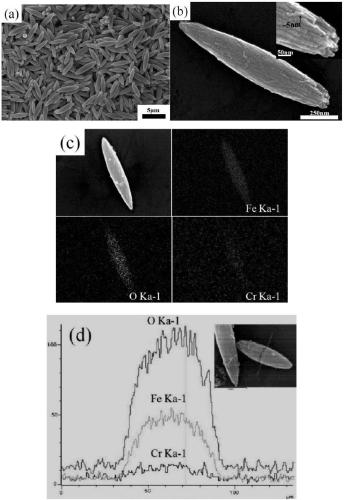

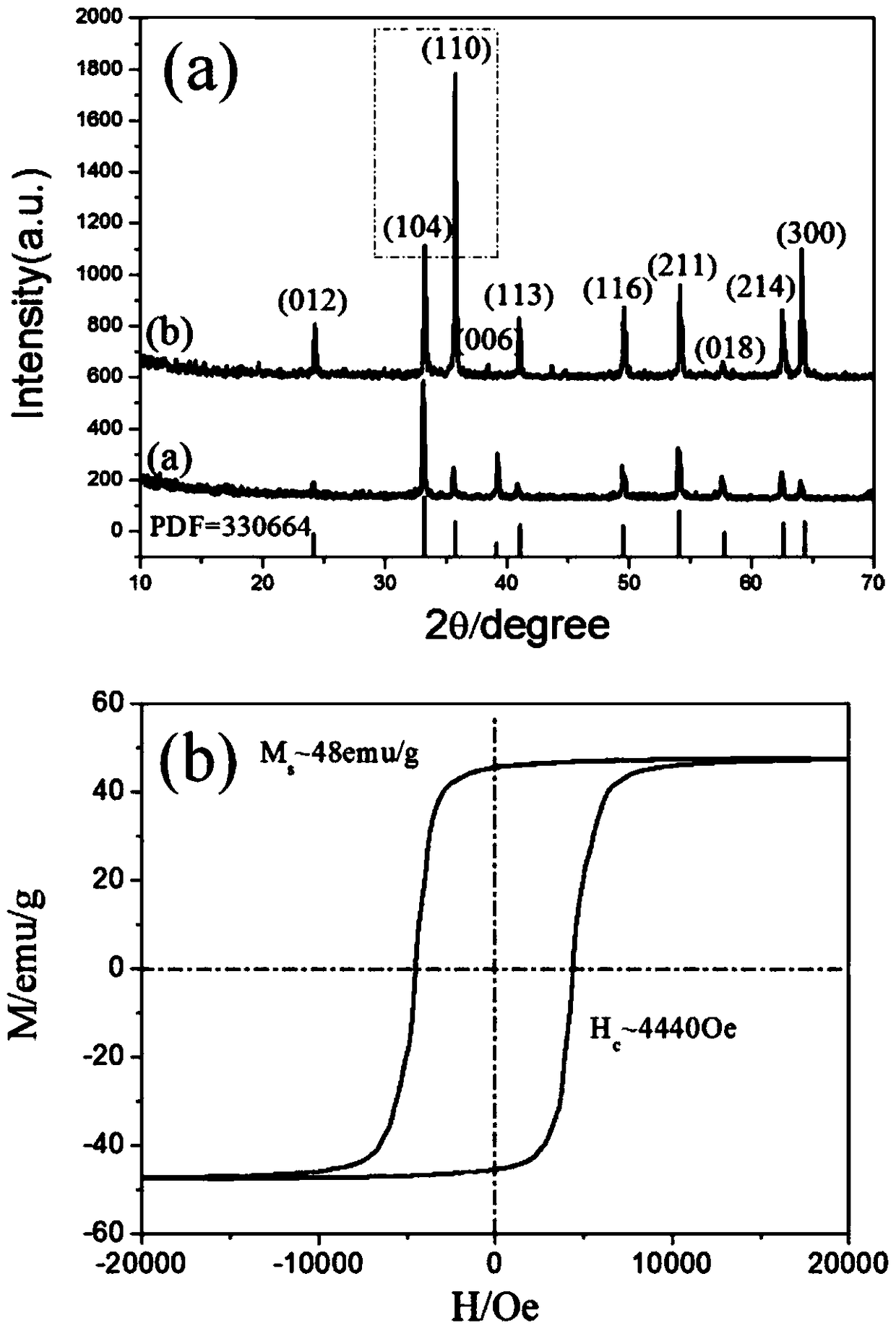

[0017] Example 1: Spindle Cr doped α-Fe 2 o 3 Preparation and characterization of micro-nanocrystals

[0018] First add 1g of Na 2 CrO 4 , 1.4g of FeCl 2 .4H 2 O was added to 50mL of deionized water, stirred and dissolved, then placed in an oven and heated to 180°C at a constant temperature. After 24 hours of reaction, the precipitate was taken out, washed and dried to obtain Cr-doped α-Fe 2 o 3 micro-nano crystals.

[0019] Depend on figure 1 a It can be seen that the prepared product is composed of some spindle-shaped particles; by figure 2 b It is further seen that the long axis of a single elliptical particle is about 1 μm, and the short axis is about 250 nm. Depend on figure 1 Inset b, it can be seen that a single spindle-shaped particle is composed of several nanorods with a diameter of about 5 nm. The surface scanning energy spectrum analysis of a single particle shows that the particle is mainly composed of Fe, O and Cr elements (see figure 1 c), the ratio...

Embodiment 2

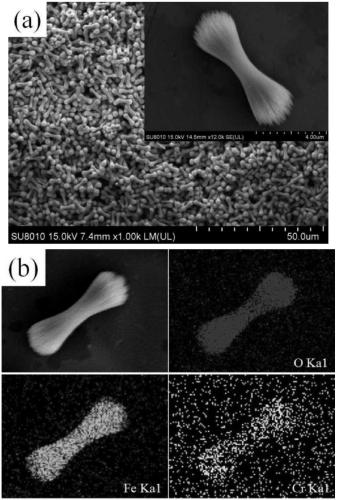

[0021] Example 2: Dumbbell-shaped Cr-doped α-Fe 2 o 3 Preparation and characterization of micro-nanocrystals

[0022] First, 1.8g of Na 2 CrO 4 , 1.4g of FeCl 2 .4H 2 O was added to 50 mL of deionized water, stirred and dissolved, then 0.6 g of hydroxylamine hydrochloride was added, and then placed in an oven and heated to 180 °C at a constant temperature. After 16 hours of reaction, the precipitate was taken out, washed and dried to obtain Cr-doped α- Fe 2 o 3 micro-nano crystals.

[0023] Preparation of spindle-type Cr-doped α-Fe in Example 1 2 o 3 In the system of micro-nano crystals, a certain amount of hydroxylamine hydrochloride is added, and the product of Example 2 obtained after the reaction is dumbbell-shaped Cr-doped α-Fe 2 o 3 micro-nanocrystals (see image 3 ), which shows that the introduction of hydroxylamine hydrochloride has a great influence on the morphology of the final product formed. Experiments have found that the addition of hydroxylamine h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com