Paper-making wastewater treatment flocculant and preparation method thereof

A paper-making wastewater and flocculant technology, which is applied in processing wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of destroying the biological chain of water body, low flocculation and sedimentation efficiency, and polymer residue. Achieve low equipment dependence, improve flocculation effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

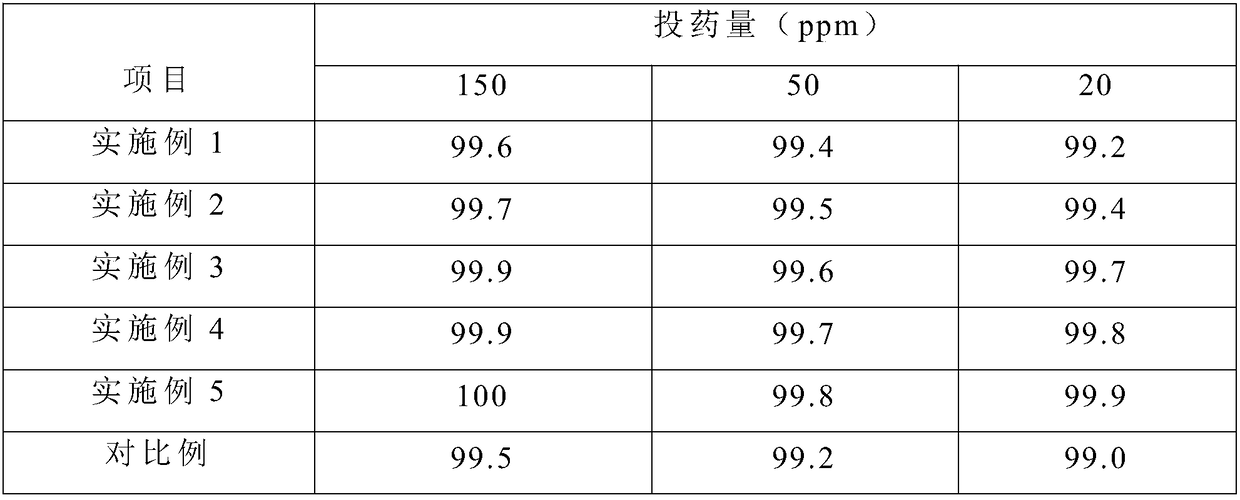

Examples

Embodiment 1

[0028] A flocculant for treating papermaking wastewater is prepared from the following components in parts by weight: 40 parts of adamantyl ferrocene polyamide, 10 parts of surface-modified polymerized aluminum iron silicate, and 10 parts of modified starch.

[0029] The adamantyl ferrocene polyamide is prepared from 1,3,5,7-tetrakis(4-aminophenyl)adamantane and 1,1'-dicarboxyferrocene through polycondensation reaction.

[0030] The preparation method of the adamantyl ferrocene polyamide comprises the following steps: 18.4 g of 1,3,5,7-tetrakis(4-aminophenyl)adamantane, 1,1'-dicarboxyferrocene Dissolve 10g of iron in 50g of dimethyl sulfoxide, react at 70°C for 0.5h at normal pressure, and react at 100°C for 1h, then add 2g of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride , 6g of 4-dimethylaminopyridine, heated to 130°C, primary polycondensation reaction for 3h, then the reaction solution was transferred to the reactor, vacuumed (500Pa), heated to 220°C, and then p...

Embodiment 2

[0037] A flocculant for treating papermaking wastewater is prepared from the following components in parts by weight: 43 parts of adamantyl ferrocene polyamide, 13 parts of surface-modified polyaluminum iron silicate and 12 parts of modified starch.

[0038] The adamantyl ferrocene polyamide is prepared from 1,3,5,7-tetrakis(4-aminophenyl)adamantane and 1,1'-dicarboxyferrocene through polycondensation reaction.

[0039] The preparation method of the adamantyl ferrocene polyamide comprises the following steps: 18.4 g of 1,3,5,7-tetrakis(4-aminophenyl)adamantane, 1,1'-dicarboxyferrocene Dissolve 10g of iron in 60g of N,N-dimethylformamide, react at 73°C for 0.7h at normal pressure, and react at 104°C for 1.2h, then add 1-ethyl-(3-dimethylaminopropyl)carbodiene Imine hydrochloride 2.5g, 4-dimethylaminopyridine 6g, heat up to 135°C, conduct primary polycondensation reaction for 3.3h, then transfer the reaction liquid into the reaction kettle, vacuumize (500Pa), heat to 223°C, and ...

Embodiment 3

[0046] A flocculant for treating papermaking wastewater is prepared from the following components in parts by weight: 45 parts of adamantyl ferrocene polyamide, 15 parts of surface-modified polymerized aluminum iron silicate, and 13 parts of modified starch.

[0047] The adamantyl ferrocene polyamide is prepared from 1,3,5,7-tetrakis(4-aminophenyl)adamantane and 1,1'-dicarboxyferrocene through polycondensation reaction.

[0048] The preparation method of the adamantyl ferrocene polyamide comprises the following steps: 18.4 g of 1,3,5,7-tetrakis(4-aminophenyl)adamantane, 1,1'-dicarboxyferrocene Dissolve 10g of iron in 70g of N-methylpyrrolidone, react at 77°C for 0.8h at normal pressure, and 1.6h at 107°C, then add 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride Salt 3g, 4-dimethylaminopyridine 6g, temperature raised to 140°C, primary polycondensation reaction for 3.6h, then the reaction solution was transferred to the reaction kettle, vacuumed (500Pa), heated to 225°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com