Magnetic separation device and method for treating oily sludge

A magnetic separation device and sludge technology, applied in sludge treatment, fertilization equipment, biological sludge treatment, etc., can solve the problems of unstable operation, large differences, long cycle, etc., and achieve good degreasing effect and wide application range Wide, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

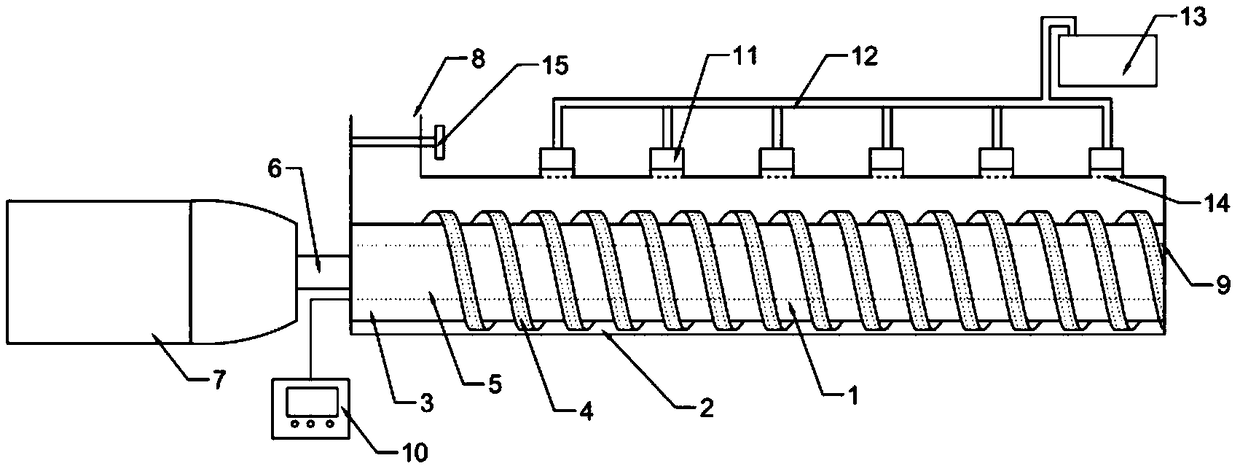

[0029] A magnetic separation device, comprising a magnetic roller 1 and a housing 2 outside the magnetic roller 1, the magnetic roller 1 includes a cylindrical rotating shaft 3 and a helical fin 4 surrounding the rotating shaft 3, the rotating shaft 3 and the helical fin 4 An electromagnet 5 is provided inside, and the electromagnet 5 is connected with a power supply (not shown in the figure), and the rotating shaft 3 is connected to the motor 7 outside the housing 2 through the transmission rod 6; A sludge inlet 8 is provided, and a sludge outlet 9 is provided at one end away from the motor 7 . The thickness of the spiral fin 4 is 3cm. The magnetic roller 1 is 2 cm away from the lower shell 2 and 8 cm away from the upper shell 2 . The magnetic roller 1 is at a certain distance from the casing 2, which is beneficial to the throwing and mixing of the sludge in the casing under the action of the rotation of the magnetic roller, which is beneficial to improving the treatment eff...

Embodiment 2

[0033] A method of treating oily sludge, comprising:

[0034] (1) The pH value of the oily sludge to be treated is adjusted to 11.5;

[0035] (2) Add Fe to the oily sludge obtained in step (1) 3 o 4 , and stir evenly;

[0036] (3) The oily sludge obtained in step (2) is processed with the magnetic separation device described in Example 1;

[0037] (4) The sludge discharged from the magnetic separation device is sent to the filter press for dehydration;

[0038] (5) Ferment the dehydrated sludge to make organic fertilizer.

[0039] The oily sludge with a water content of 88% and an oil content of 10% was treated according to the above steps. The control group was directly dehydrated by a filter press, and the water content, oil content, etc. of the treated sludge were measured respectively. The data are as follows :

[0040] Table 1 Comparison of treatment effects

[0041]

[0042] From the above experimental results, it can be seen that the device and method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com