Method for preparing 1,5-pentanediamine

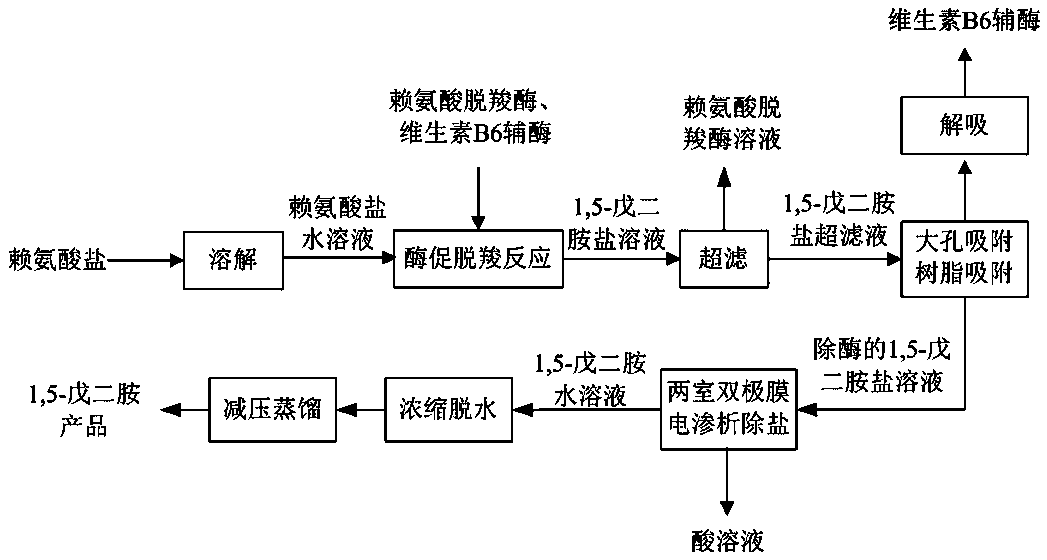

A technology for pentamethylenediamine and pentamethylenediamine salt, which is applied in the field of preparation of 1,5-pentamethylenediamine, can solve the problems of low product purity, high production cost, high environmental protection pressure, etc., achieves high overall yield and reduces environmental protection Pressure, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A, 250g lysine hydrochloride is dissolved in water, obtains the lysine hydrochloride aqueous solution that pH value is 6.6;

[0031] b. Add lysine decarboxylase and pyridoxal phosphate to the lysine hydrochloride aqueous solution obtained in step a, and perform enzymatic decarboxylation of lysine at 32°C to obtain 1,5-pentanediamine Hydrochloride solution, adding hydrochloric acid solution during the reaction to maintain a pH value of 6.6;

[0032] Among them, the dosage of lysine decarboxylase is 3% of the mass of lysine salt, the dosage of vitamin B6 coenzyme is 6.5‰ of the mass of lysine salt, and the conversion rate of lysine is 99.96%.

[0033] c, using an ultrafiltration membrane with a molecular weight cut-off of 5000 to filter the 1,5-pentanediamine hydrochloride solution obtained in step b to obtain a 1,5-pentanediamine hydrochloride ultrafiltrate containing pyridoxal phosphate and lysine decarboxylase solution, the separated lysine decarboxylase solution is r...

Embodiment 2

[0041] A, 340g lysine sulfate is dissolved in water, obtains the lysine sulfate aqueous solution that pH value is 6.1;

[0042] b. Add lysine decarboxylase and pyridoxal to the lysine sulfate aqueous solution obtained in step a, and perform enzymatic decarboxylation of lysine at 36° C. to obtain 1,5-pentamethylenediamine sulfate Solution, add sulfuric acid solution in reaction process and maintain pH value to be 6.1;

[0043] Wherein, the dosage of lysine decarboxylase is 4% of the mass of lysine sulfate, the dosage of pyridoxal is 5‰ of the mass of lysine sulfate, and the conversion rate of lysine is 99.91%.

[0044] c, the 1,5-pentanediamine sulfate solution obtained in step b is filtered using an ultrafiltration membrane with a molecular weight cut-off of 6000 to obtain the 1,5-pentanediamine sulfate ultrafiltrate containing pyridoxal and lysine Acid decarboxylase solution, the separated lysine decarboxylase solution is recycled after treatment;

[0045] d, using LXT-021 ...

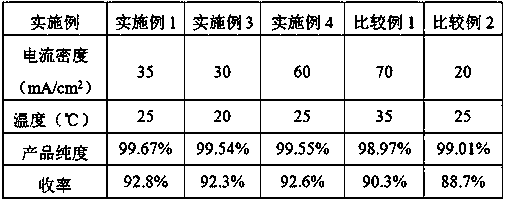

Embodiment 3~4、 comparative example 1~2

[0052] The current density and temperature of the two-chamber bipolar membrane electrodialysis device were changed (see Table 1 for details), and other conditions were the same as in Example 1. The test results are shown in Table 1.

[0053] Table 1:

[0054]

[0055] It can be seen from Table 1 that the present invention adopts the bipolar membrane electrodialysis desalination technology with specific conditions to significantly improve the product purity, and under the current density and temperature conditions of the present invention, it can ensure that the obtained product has a higher purity (>99.5%) and Yield (>99.2%), beyond the current density and temperature range limited by the present invention, the product purity and yield are obviously reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com