A method for preparing disodium glycyrrhizinate

A technology of disodium glycyrrhizinate and monoammonium glycyrrhizinate, applied in the field of chemistry, can solve the problems of residual ammonium, low yield, poor product quality and the like, achieves easy operation, improved product quality and yield, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

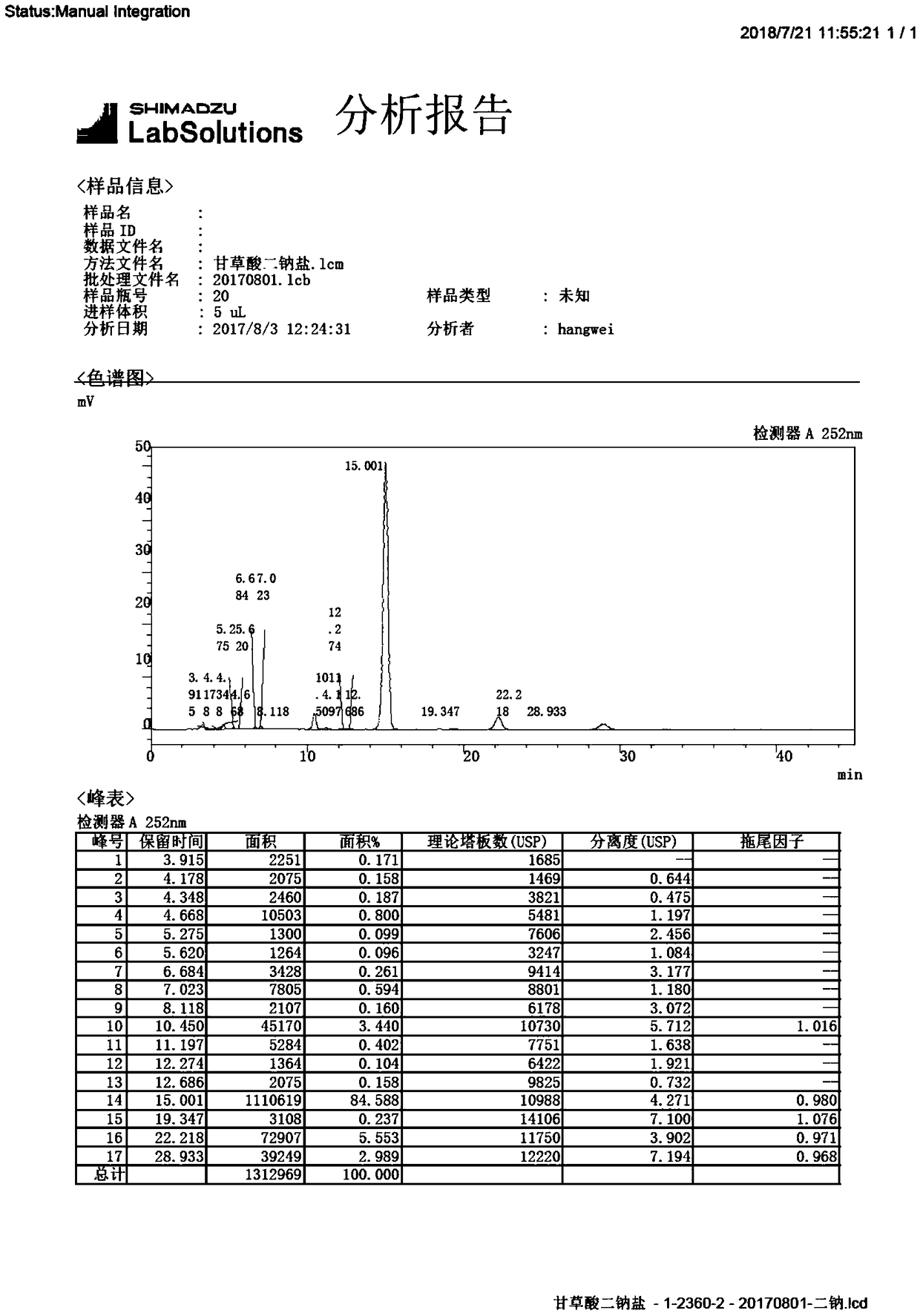

[0022] Weigh 300g monoammonium glycyrrhizinate, add 1200mL 20% ethanol and stir to dissolve, add 600g cation exchange resin and stir for a period of time, filter to obtain the converted solution of monoammonium glycyrrhizinate, add 5% activated carbon by weight of monoammonium glycyrrhizinate Stir and decolorize in a water bath at 40°C for 1 hour, add 20 g of sodium hydroxide to the decolorized solution after filtration, stir for 30 minutes, concentrate to remove ethanol, and spray-dry the concentrated solution obtained by filtration at 70°C to obtain 288.0 g of the finished product of disodium glycyrrhizinate, yield It is 93.2%, and the product purity is 84.6%, and the liquid chromatogram sees figure 1 .

Embodiment 2

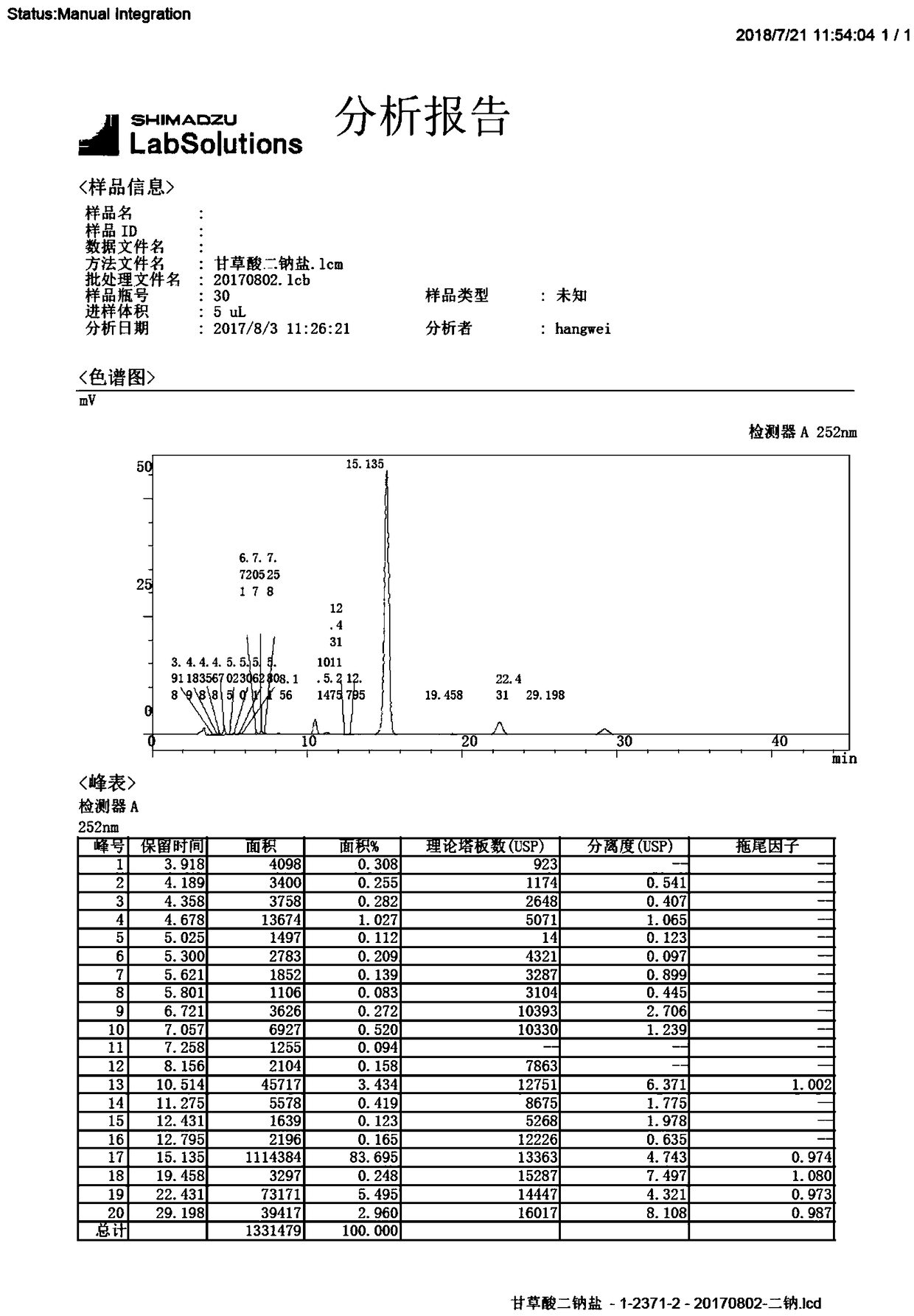

[0024] Weigh 400g of monoammonium glycyrrhizinate, add 2000mL of 30% ethanol and stir to dissolve, add 1200g of cation exchange resin and stir for a period of 1.5h, filter to obtain the converted solution of monoammonium glycyrrhizinate, add 8% by weight of monoammonium glycyrrhizinate Activated carbon was stirred and decolorized in a water bath at 50°C for 1.5h, filtered to obtain a decolorized solution, added 27g of sodium hydroxide, stirred for 30min, concentrated to remove ethanol, and the concentrated solution obtained by filtration was spray-dried at 70°C to obtain 380.0g of the finished product of disodium glycyrrhizinate. Yield is 92.2%, and product purity is 83.7%, and liquid chromatogram sees figure 2 .

Embodiment 3

[0026] Weigh 500g of monoammonium glycyrrhizinate, add 3000ml of 40% ethanol and stir to dissolve, add 2000g of cation exchange resin and stir for a period of 12 hours, filter to obtain the converted solution of monoammonium glycyrrhizinate, add 10% activated carbon by weight of monoammonium glycyrrhizinate Stir and decolorize in a water bath at 60°C for 2 hours, add 33g of sodium hydroxide to the decolorized solution after filtration, stir for 30min, concentrate to remove ethanol, and spray-dry the concentrated solution obtained by filtration at 70°C to obtain 475.0g of the finished product of disodium glycyrrhizinate. It is 92.2%, and the product purity is 82.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com