A phosphor matrix material and its preparation method

A technology of matrix material and phosphor powder, which is applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of no discovery, and achieve the effects of easy control of crystal shape, low reaction temperature and high phase purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] LiGd(MoO was prepared by the following steps 4 ) 2 :

[0031] (1) According to LiGd(MoO 4 ) 2 The stoichiometric ratio of Gd and Mo elements in the medium was weighed 3.5mmol of Gd(NO 3 ) 3 ·6H 2 O and 7 mmol Li 2 MoO 4 And ground into powder and dissolved in deionized water to obtain solution A and solution B respectively;

[0032] (2) Slowly drop solution A in step (1) into solution B, and magnetically stir at room temperature for 60 minutes to obtain a mixed milky white solution;

[0033] (3) select LiOH solution to adjust the pH of the mixed milky solution in step (2) to be 7 and add urea, so that the concentration of urea is 0.15mol / L, to obtain the precursor solution;

[0034] (4) Transfer the precursor liquid obtained in step (3) into a p-polyphenylene-lined stainless steel reaction kettle, the volume filling degree of the reaction kettle is 65%, seal and react at 240° C. for 24 hours to form a white precipitate, and cool to room temperature;

[0035] (...

Embodiment 2

[0038] LiGd(MoO was prepared by the following steps 4 ) 2 :

[0039] (1) According to LiGd(MoO 4 ) 2 The stoichiometric ratio of Gd and Mo elements in the medium was weighed 3.5mmol of Gd(NO 3 ) 3 ·6H 2 O and 7 mmol Li 2 MoO 4 And ground into powder and dissolved in deionized water to obtain solution A and solution B respectively;

[0040] (2) Slowly drop solution A obtained in step (1) into solution B, and then magnetically stir at room temperature for 70 minutes to obtain a mixed milky white solution;

[0041] (3) select LiOH solution to adjust the pH of the mixed milky white solution obtained in step (2) to be 8, and add urea, so that the concentration of urea is 0.25mol / L, to obtain the precursor solution;

[0042] (4) Transfer the precursor liquid obtained in step (3) into a p-polyphenylene-lined stainless steel reaction kettle, the volume filling degree of the reaction kettle is 65%, seal and react at 240° C. for 24 hours to form a white precipitate, and cool to...

Embodiment 3

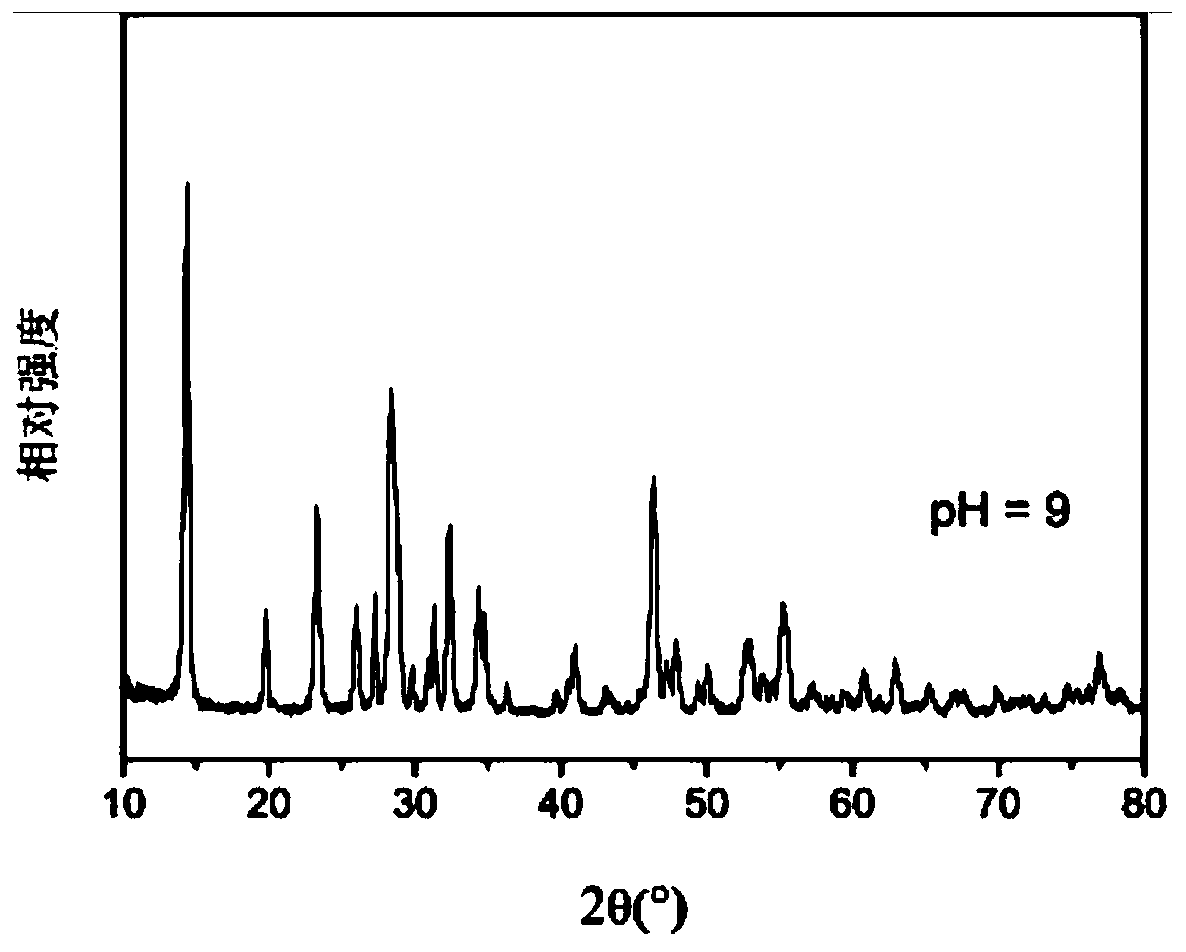

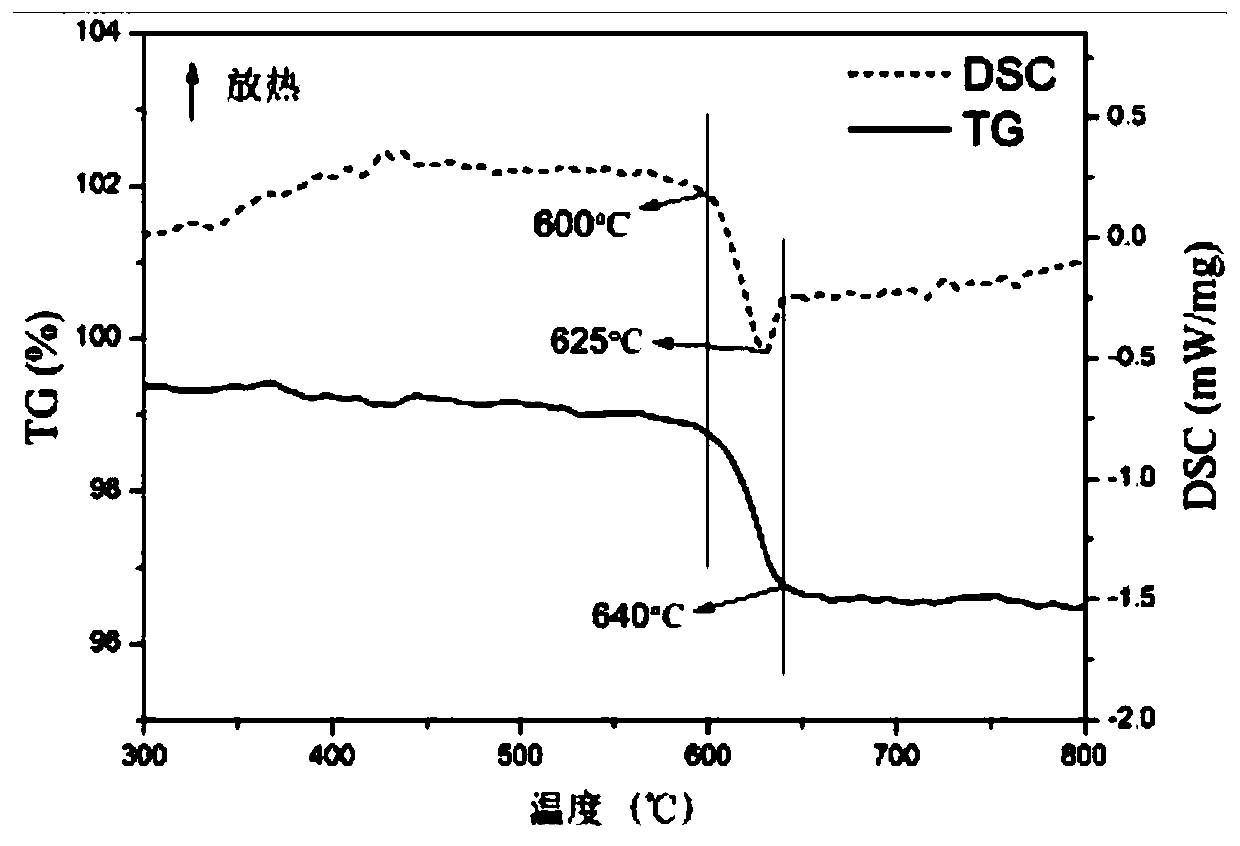

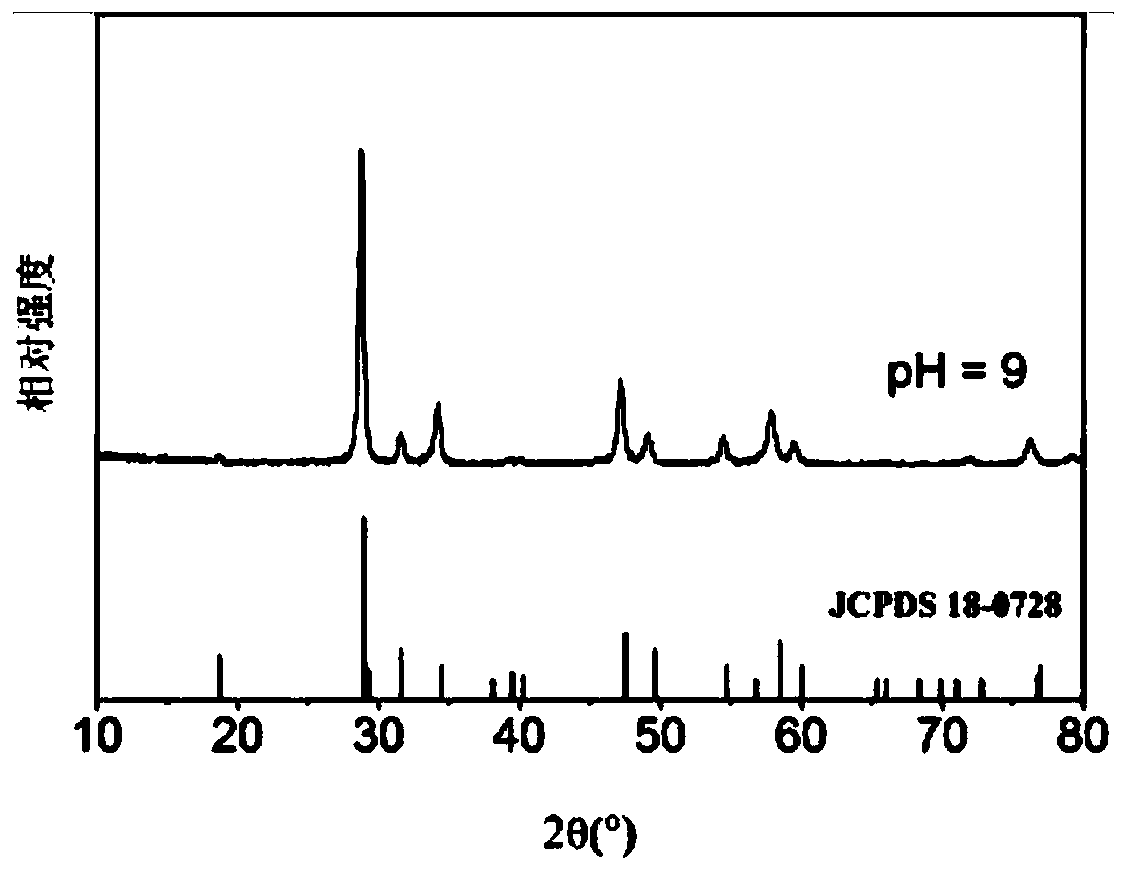

[0046] LiGd(MoO was prepared by the following steps 4 ) 2 :

[0047](1) According to LiGd(MoO 4 ) 2 The stoichiometric ratio of Gd and Mo elements in the medium was weighed 3.5mmol of Gd(NO 3 ) 3 ·6H 2 O and 7 mmol Li 2 MoO 4 And ground into powder and dissolved in deionized water to obtain solution A and solution B respectively;

[0048] (2) Slowly drop solution A obtained in step (1) into solution B and magnetically stir for 80 minutes at room temperature to obtain a mixed milky white solution;

[0049] (3) select LiOH solution to adjust the pH=9 of the mixed opalescent solution obtained in step (2), and add urea so that the concentration of urea is 0.25mol / L to obtain the precursor solution;

[0050] (4) Transfer the precursor liquid obtained in step (3) into a p-polyphenylene-lined stainless steel reaction kettle, the volume filling degree of the reaction kettle is 65%, seal and react at 240° C. for 24 hours to form a white precipitate, and cool to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com