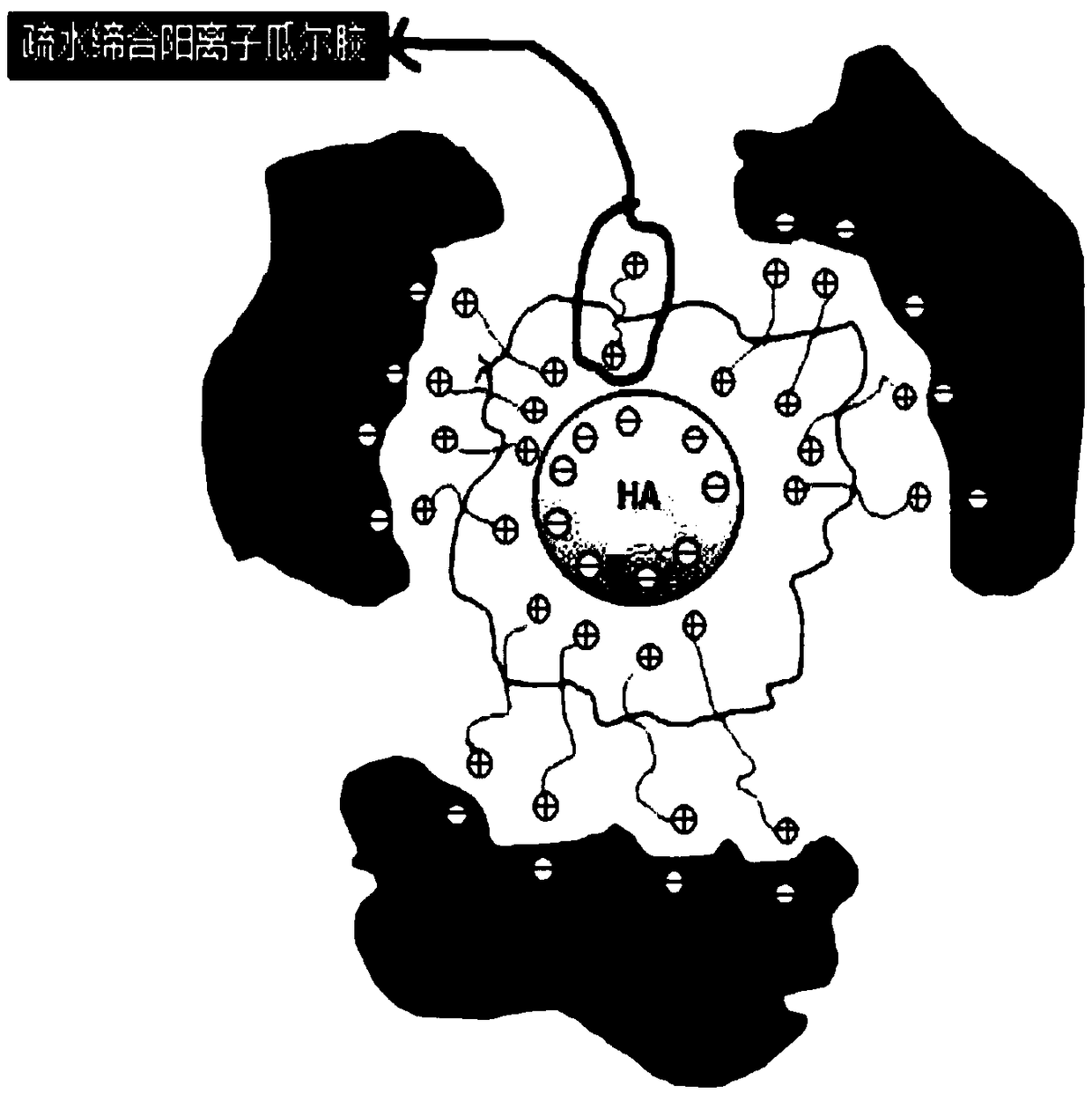

Sand-fixation agent of humic acid wrapped with degradable natural macromolecular compound, and preparation method thereof

A technology of natural polymer and humic acid, applied in chemical instruments and methods, fertilizer mixtures, other chemical processes, etc., can solve the problems of soil improvement and poor effect, and achieve the advantages of improving soil, simple preparation process and improving sand fixation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

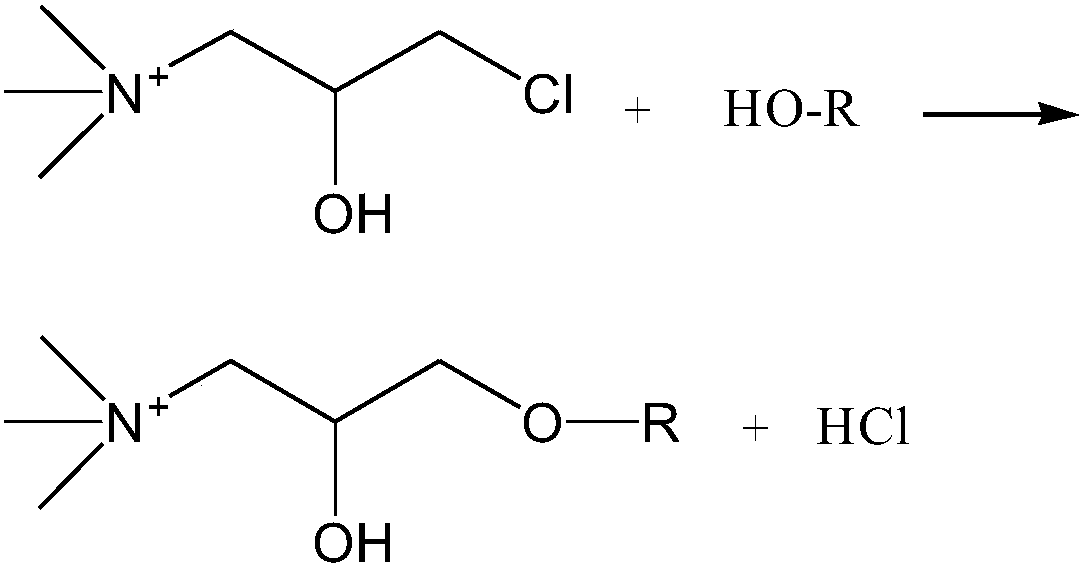

[0042] (1) Starch cationic modification

[0043] Weigh 20 parts of starch, make a starch emulsion with an ethanol solution made of 25.5 parts of ethanol and 4.5 parts of water, pour it into a four-neck flask, stir, heat in a water bath to 70°C, and add 0.075mol / L sodium hydroxide ethanol solution Adjust the pH of the starch emulsion to be alkaline, add dropwise an etherification agent made of 1.4 parts of 3-chloro-2 hydroxypropyltrimethylammonium chloride and 0.6 parts of water, and control the system with 0.075 mol / L sodium hydroxide ethanol solution The pH is constant. After the reaction, the pH of the system is adjusted to 6 with 2.0 mol / L hydrochloric acid, and the quaternary ammonium salt type cationic starch product is obtained through dehydration, alcohol washing, drying and sieving.

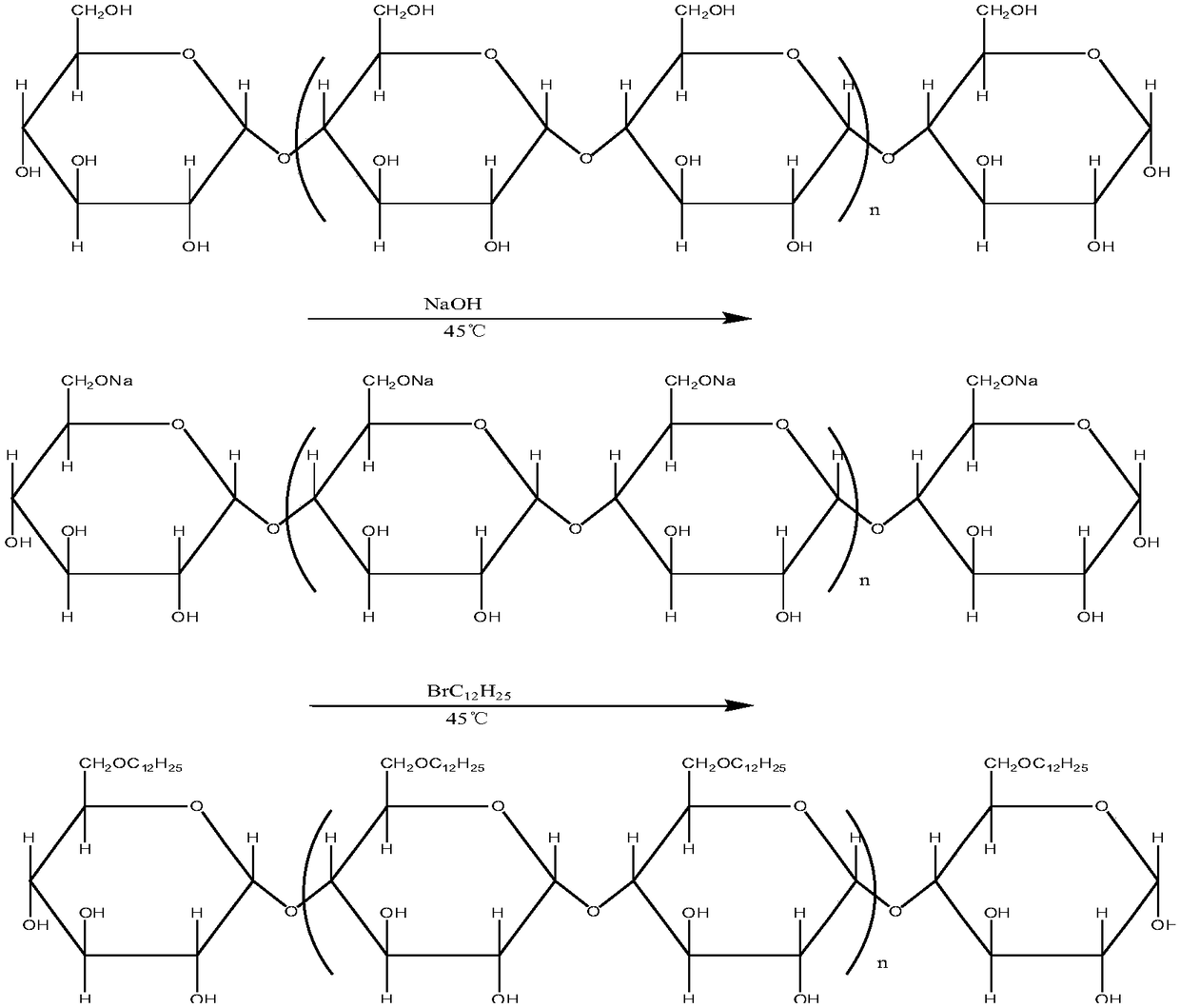

[0044] (2) Synthesis of Hydrophobic Association Cationic Starch Solution

[0045] Add 15 parts of dried cationic starch and 28 parts of ethanol to a three-necked flask with a stirring de...

Embodiment 2

[0051] (1) Starch cationic modification

[0052]Weigh 20 parts of starch, make a starch emulsion with an ethanol solution made of 25.5 parts of ethanol and 4.5 parts of water, pour it into a four-neck flask, stir, heat in a water bath to 70°C, and add 0.075mol / L sodium hydroxide ethanol solution Adjust the pH of the starch emulsion to be alkaline, add an etherification agent made of 1.3 parts of 3-chloro-2 hydroxypropyltrimethylammonium chloride and 0.7 parts of water dropwise, and control the system with 0.075mol / L sodium hydroxide ethanol solution The pH is constant. After the reaction, the pH of the system is adjusted to 6 with 2.0 mol / L hydrochloric acid, and the quaternary ammonium salt type cationic starch product is obtained through dehydration, alcohol washing, drying and sieving.

[0053] (2) Synthesis of Hydrophobic Association Cationic Starch Solution

[0054] Add 15 parts of dried cationic starch and 28 parts of ethanol to a three-necked flask with a stirring devi...

Embodiment 3

[0060] (1) Starch cationic modification

[0061] Weigh 20 parts of starch, make a starch emulsion with an ethanol solution made of 25.5 parts of ethanol and 4.5 parts of water, pour it into a four-neck flask, stir, heat in a water bath to 70°C, and add 0.075mol / L sodium hydroxide ethanol solution Adjust the pH of the starch emulsion to be alkaline, add an etherification agent made of 1.35 parts of 3-chloro-2 hydroxypropyltrimethylammonium chloride and 0.65 parts of water dropwise, and control the system with 0.075 mol / L sodium hydroxide ethanol solution The pH is constant. After the reaction, the pH of the system is adjusted to 6 with 2.0 mol / L hydrochloric acid, and the quaternary ammonium salt type cationic starch product is obtained through dehydration, alcohol washing, drying and sieving.

[0062] (2) Synthesis of Hydrophobic Association Cationic Starch Solution

[0063] Add 15 parts of dried cationic starch and 28 parts of ethanol to a three-necked flask with a stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com