High-pressure efficient batch molding method for hollow bricks on basis of microbial soil fixation

A molding method and hollow brick technology are applied in the field of hollow brick forming, which can solve the problems of polluting the environment and consuming high-temperature energy, and achieve the effects of protecting the environment, reducing the reaction time and making the reaction sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] A batch high-efficiency molding method for high-pressure microbial soil-fixing hollow bricks, the method comprising the following steps:

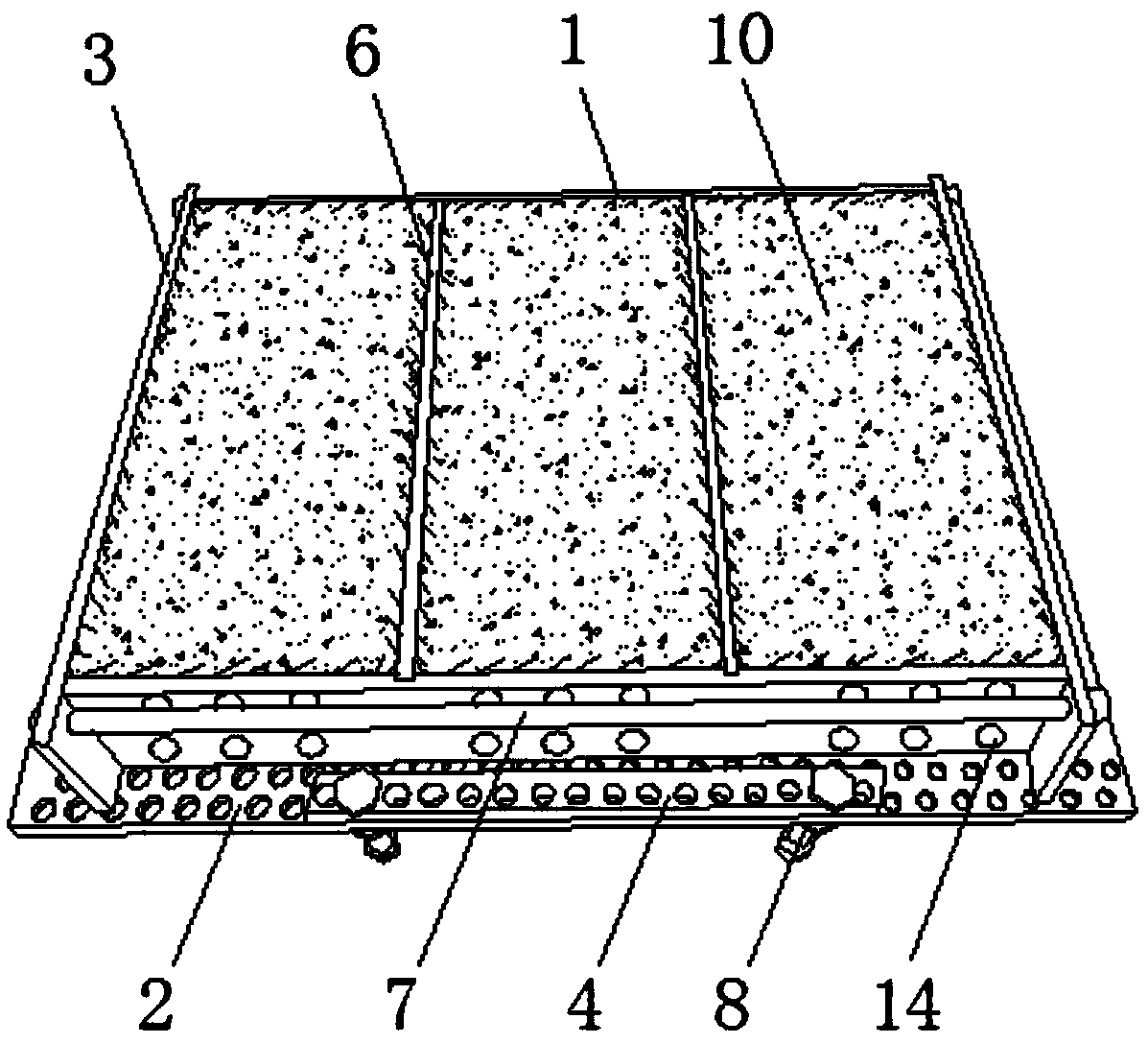

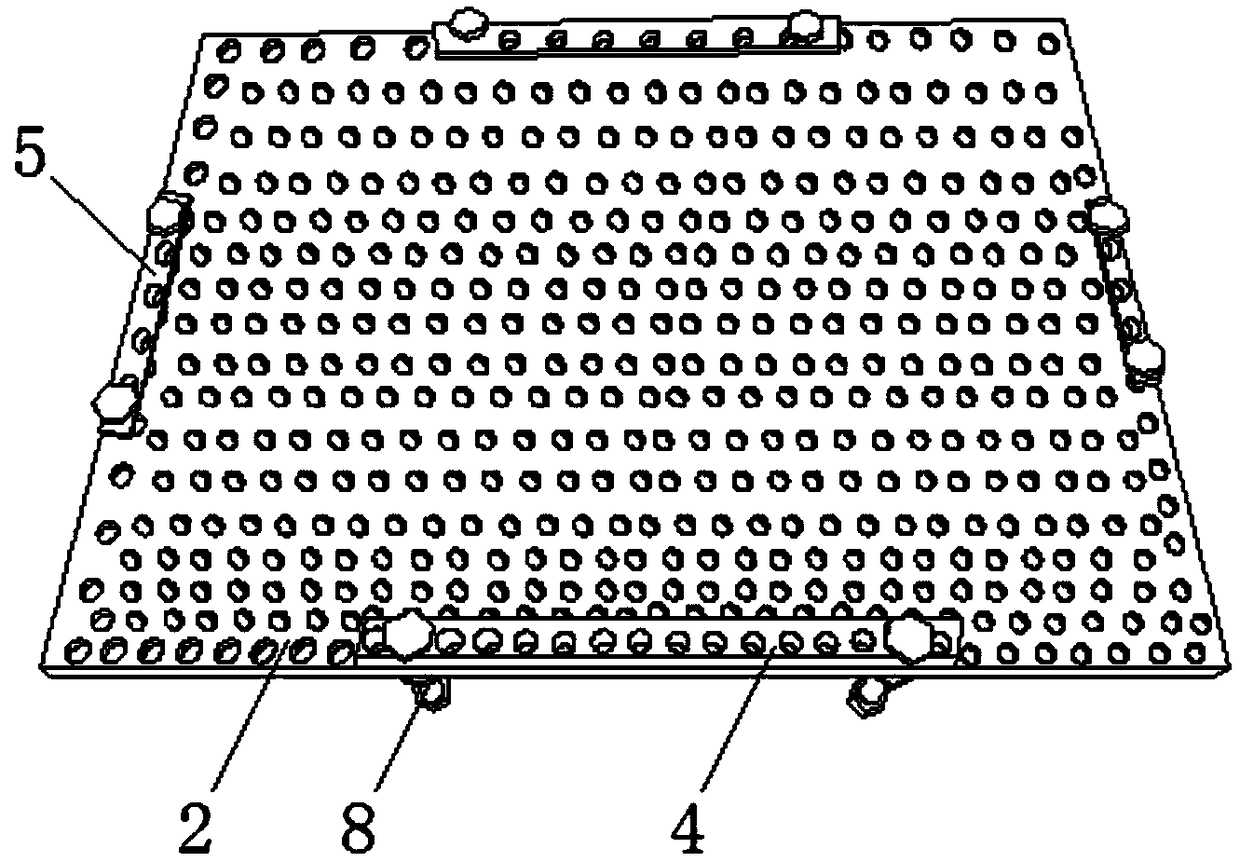

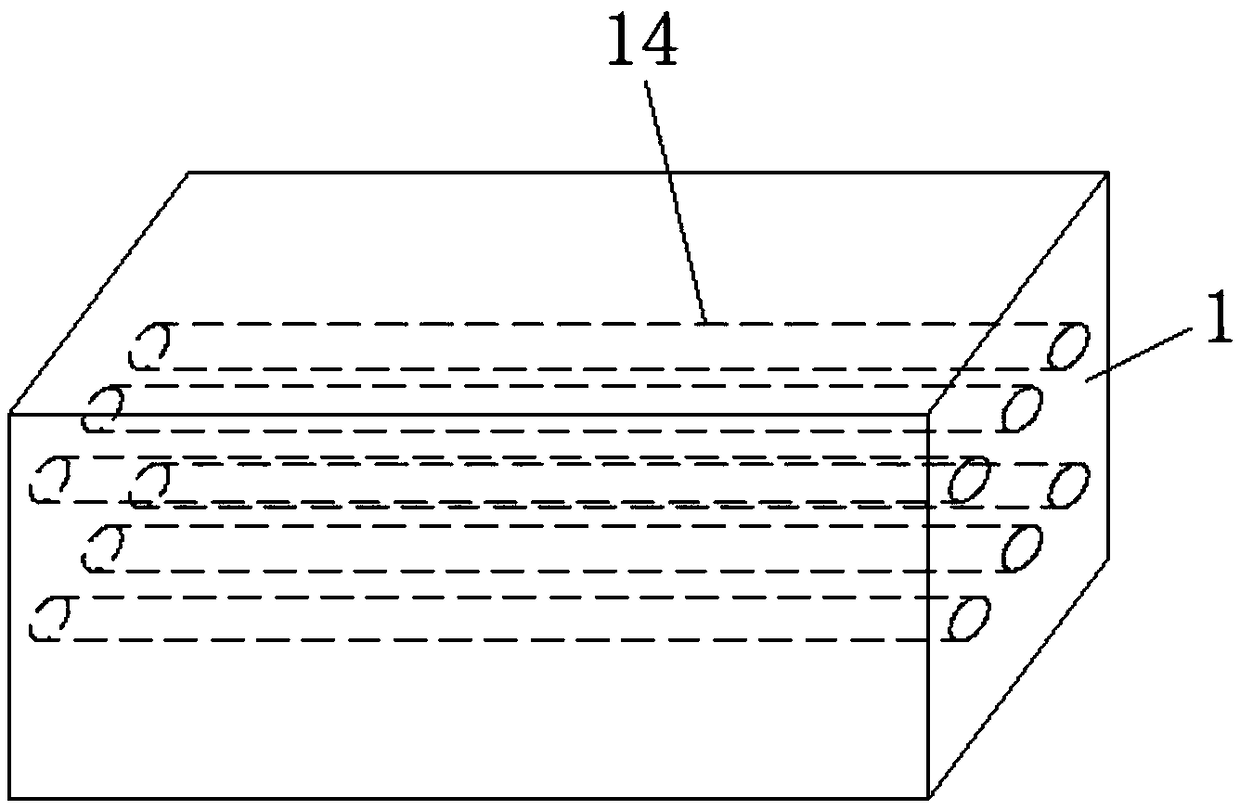

[0050] 1) Prepare the materials needed for the mold (such as figure 1 , 2 Shown): Prepare the longitudinal side plate 1, the bottom plate 2, the end plate 3, the longitudinal side plate positioning plate 4, the end plate positioning plate 5 and the partition plate 6. The vertical side plate 1, the base plate 2, the end plate 3, the longitudinal side plate positioning plate 4, the end plate positioning plate 5 and the partition plate 6 are organic glass plates with holes, and the holes on the organic glass plate are arranged in dislocation. The plexiglass plate with holes can be obtained by drilling holes in the plexiglass flat plate, or by purchasing ready-made plexiglass with holes. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com