A kind of preparation method of biomass hard carbon material for sodium ion battery negative electrode

A sodium-ion battery, biomass technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of difficult to meet the commercialization requirements of sodium-ion batteries, low capacity of hard carbon materials, etc., and achieve good industrialization. Prospect, beneficial to de-intercalation and adsorption, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0030] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0031] 2) Under the argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1000 °C at a rate of 5 °C / min in a tube furnace, keep it for 1 hour, and then increase the temperature at a rate of 2 °C / min to 1200°C, and keep warm for 1h;

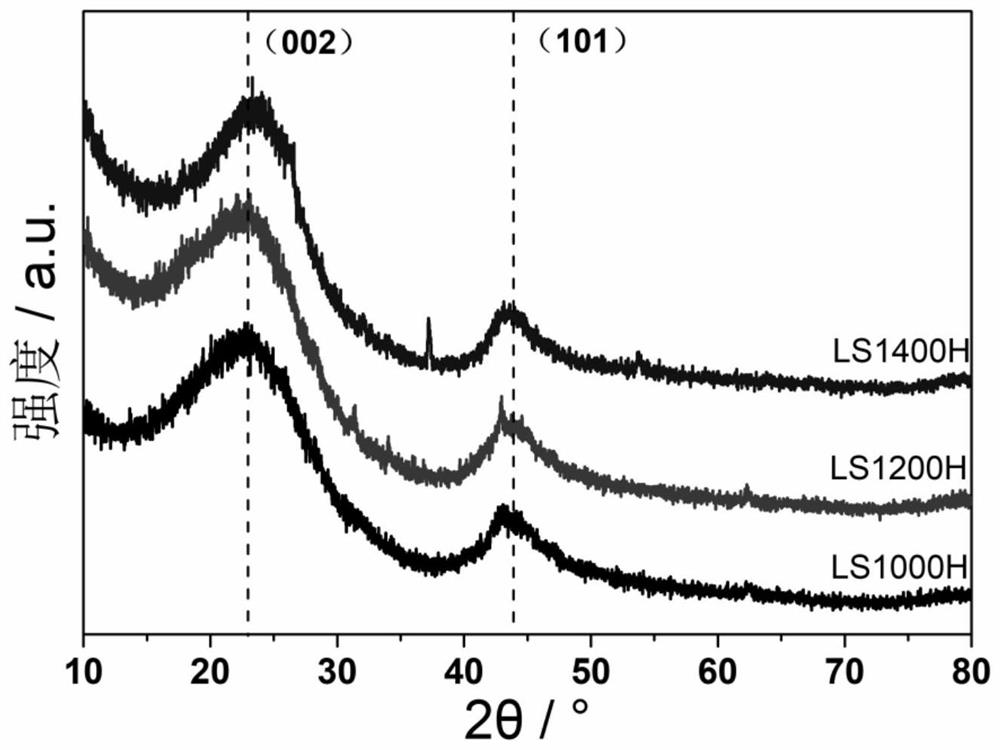

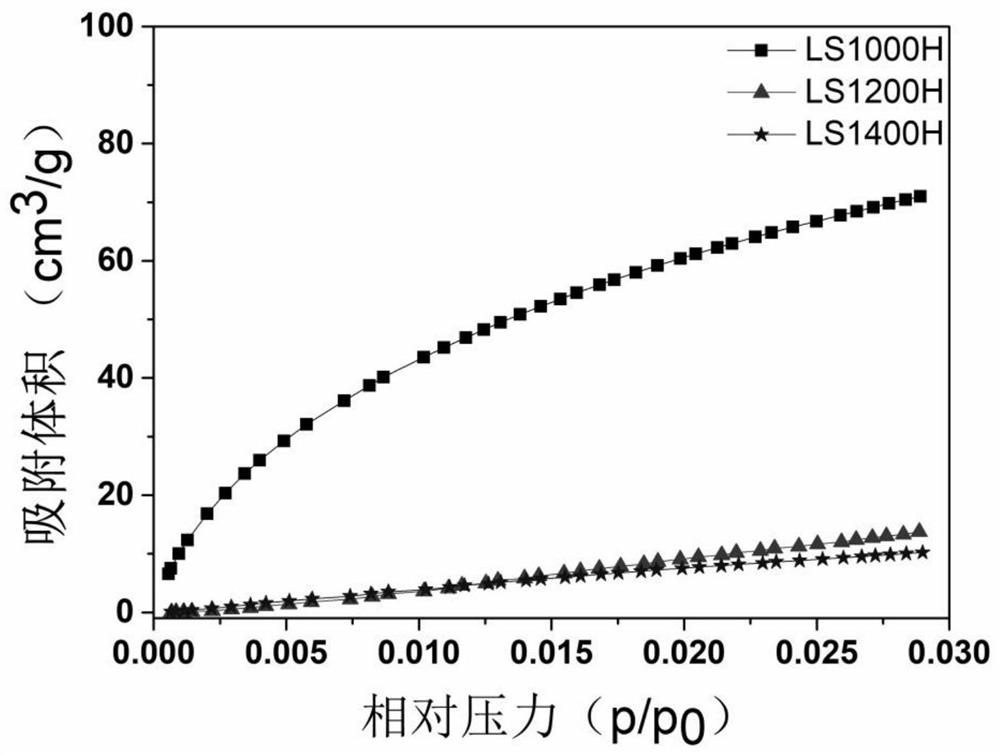

[0032] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions Biomass hard carbon material for battery negative electrode, marked as LS1200H.

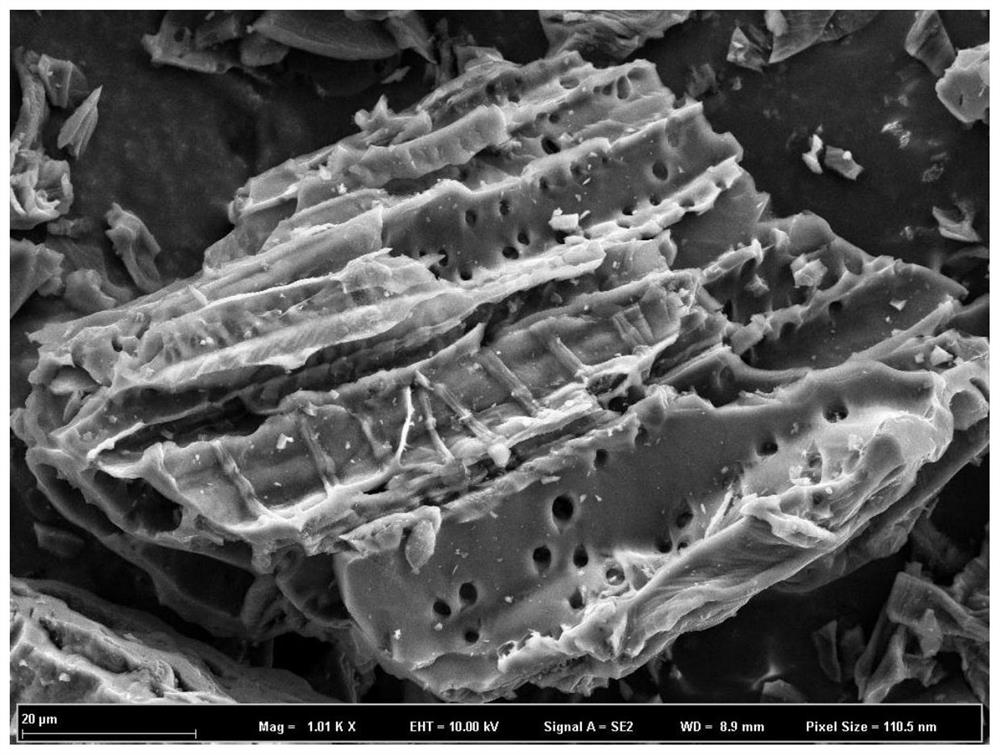

[0033] figure 1 For the SEM image of the biomass hard carbon material prepared in this example, it can be seen that there are many micron-sized holes in the mate...

Embodiment 2

[0036] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0037] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0038] 2) Under an argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1000°C at a rate of 5°C / min in a tube furnace, and keep it warm for 2h;

[0039] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions Biomass hard carbon material for battery negative electrode, marked as LS1000H.

Embodiment 3

[0041] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0042] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0043] 2) Under an argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1400°C at a rate of 5°C / min in a tube furnace, and keep it warm for 2h;

[0044] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions The biomass hard carbon material used for the negative electrode of the battery is marked as LS1400H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com