A preparation method of biomass hard carbon material for negative electrode of sodium ion battery

A sodium-ion battery, biomass material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low capacity of hard carbon materials, difficult to meet the requirements of commercialization of sodium-ion batteries, etc. Beneficial to de-intercalation and adsorption, good industrialization prospects, and cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

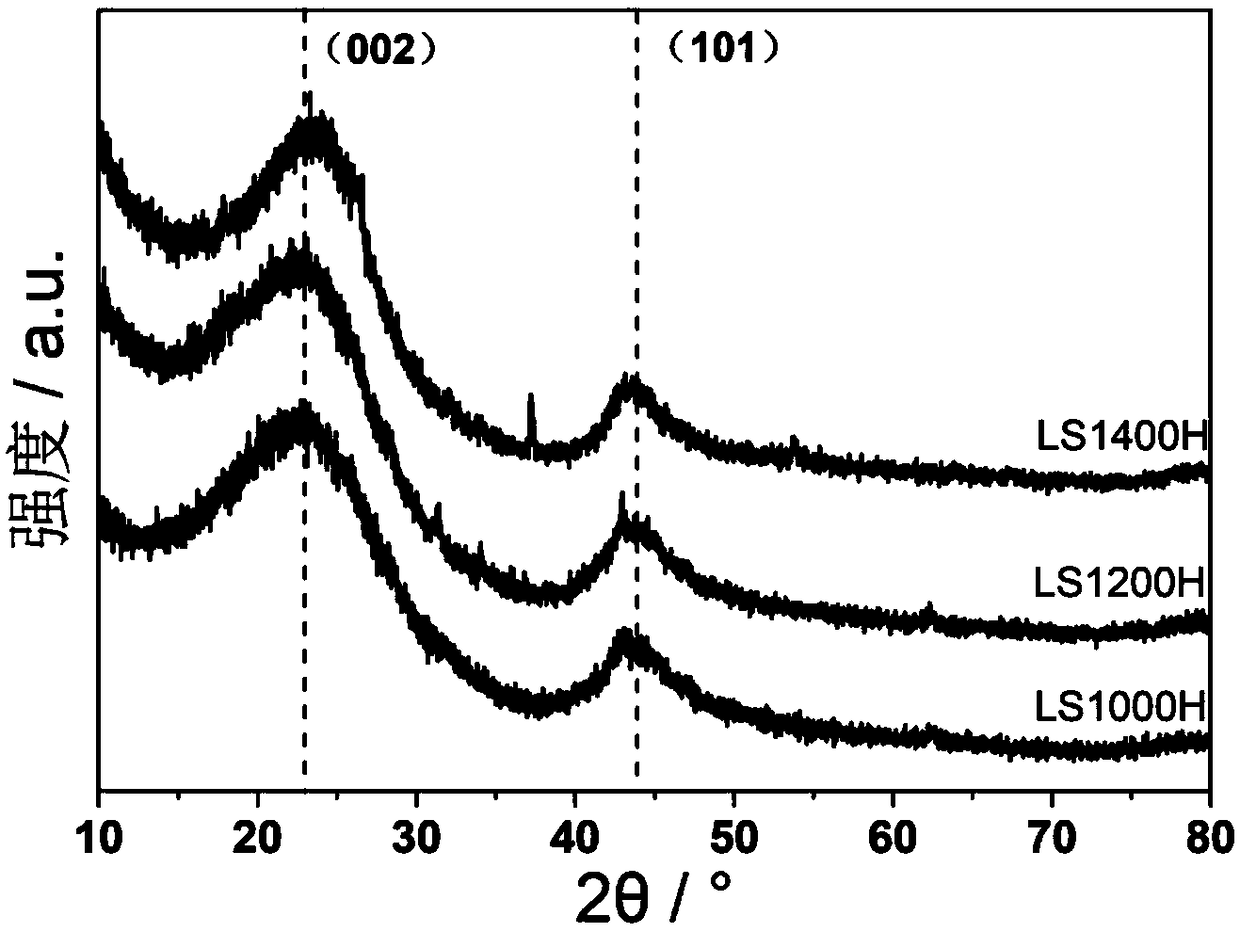

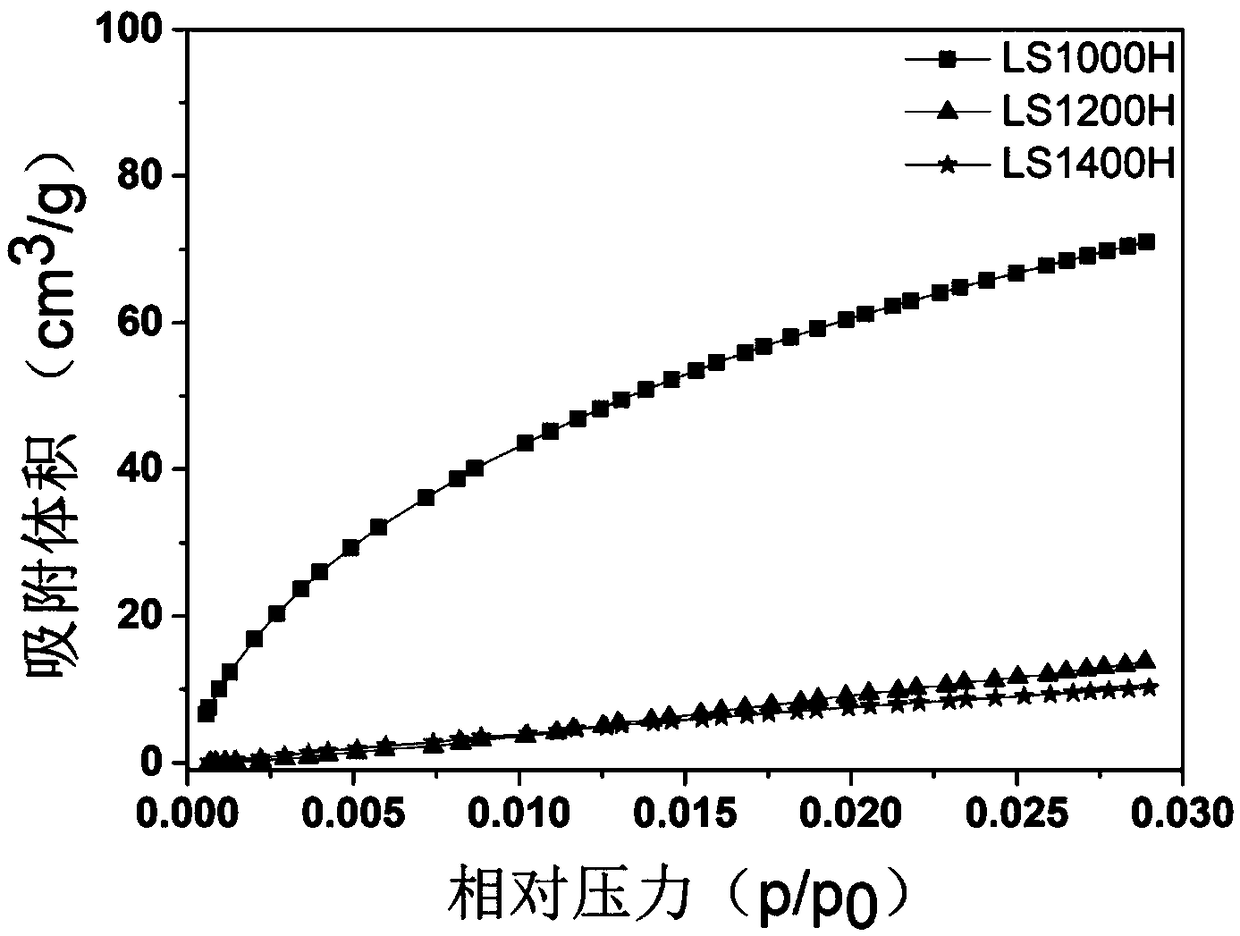

[0029] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0030] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0031] 2) Under the argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1000 °C at a rate of 5 °C / min in a tube furnace, keep it for 1 hour, and then increase the temperature at a rate of 2 °C / min to 1200°C, and keep warm for 1h;

[0032] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions Biomass hard carbon material for battery negative electrode, marked as LS1200H.

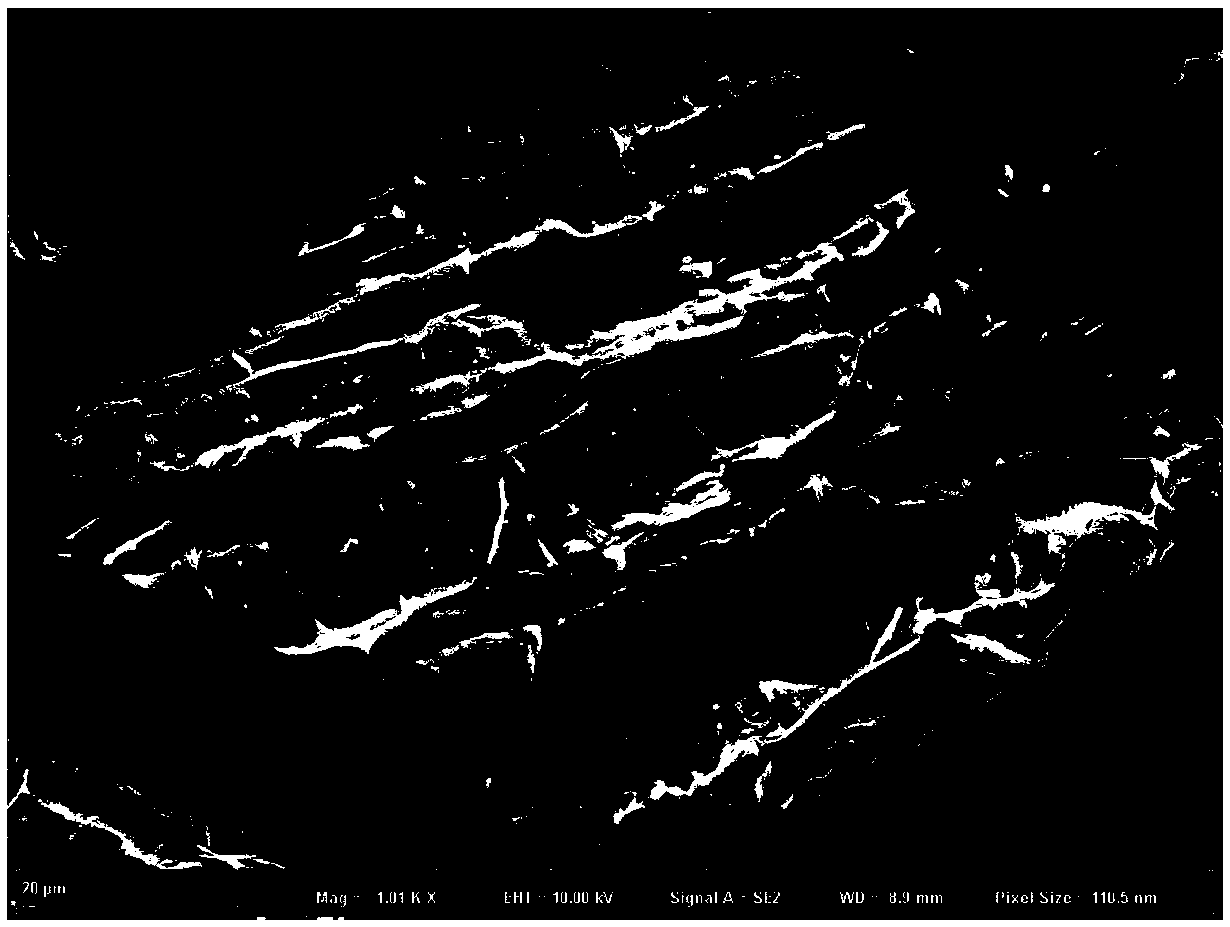

[0033] figure 1 For the SEM image of the biomass hard carbon material prepared in this example, it can be seen that there are many micron-sized holes in the mate...

Embodiment 2

[0036] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0037] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0038] 2) Under an argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1000°C at a rate of 5°C / min in a tube furnace, and keep it warm for 2h;

[0039] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions Biomass hard carbon material for battery negative electrode, marked as LS1000H.

Embodiment 3

[0041] A preparation method of biomass hard carbon material for sodium ion battery negative electrode, comprising the following steps:

[0042] 1) Wash the lotus pods with deionized water and dry them in a vacuum oven at 80°C for 24 hours;

[0043] 2) Under an argon atmosphere with a flow rate of 200 sccm, heat the material obtained in step 1) to 1400°C at a rate of 5°C / min in a tube furnace, and keep it warm for 2h;

[0044] 3) Grind the material obtained in step 2) into powder, stir in 1M hydrochloric acid solution for 12 hours, then wash with deionized water until neutral, and vacuum dry in a vacuum oven at 80°C for 12 hours to obtain sodium ions The biomass hard carbon material used for the negative electrode of the battery is marked as LS1400H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com