A kind of composite solid electrolyte membrane and its preparation method and use

A solid electrolyte membrane, electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

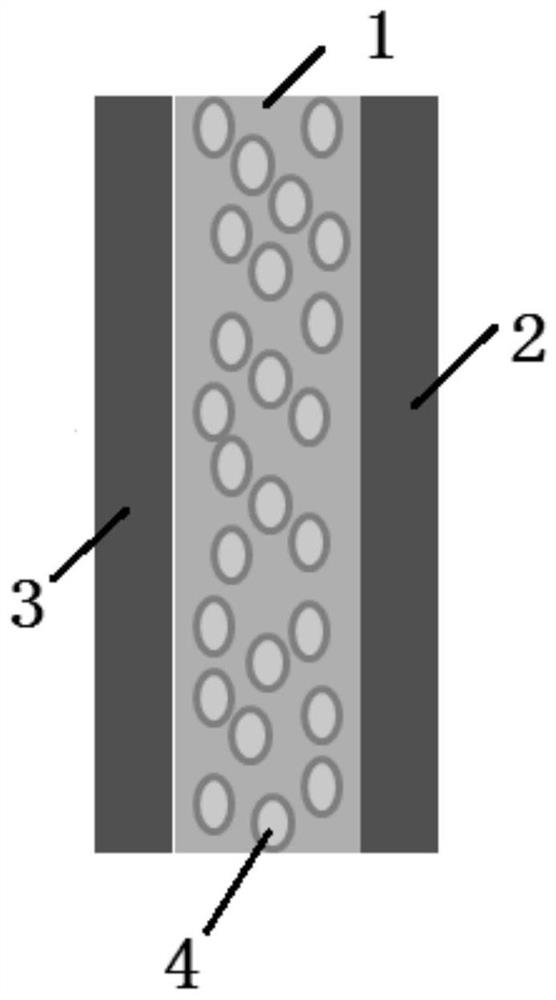

[0057] A composite solid electrolyte membrane, such as figure 1 As shown, it has a sandwich structure, including the base membrane of the middle layer, that is, the cellulose separator 1, with a porosity of 45%, a pore size distribution of 2-3 μm, and a thickness of 30 μm, and solid-state membranes coated on both sides of the membrane with a thickness of 2 μm respectively. Polymer electrolyte 2, and solid polymer electrolyte 3, both of which are composed of PEO; ceramic ion conductor powder 4 with a particle size of 2 μm (composed of Li 5 La 3 Nb 2 o 12 ) is anchored in the pores of the cellulose membrane 1 through the binder PEO, and the mass ratio of the ceramic ion conductor powder to the binder is 10:1.

[0058] Its preparation method steps are as follows:

[0059] (1) Ceramic ion conductor powder and binder are dispersed in solvent ethanol to make slurry, ceramic ion conductor powder: binder: mass ratio=10:1:30 of solvent, stir 1200min to obtain slurry, slurry is coat...

Embodiment 2

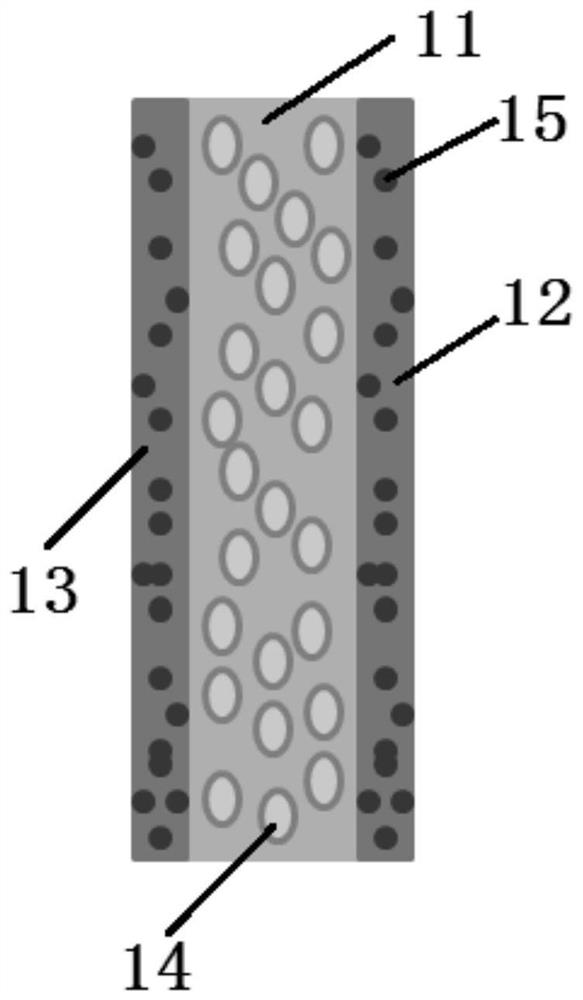

[0062] A composite solid electrolyte membrane, such as figure 2 As shown, there is a sandwich structure, including a PET separator 11 of an intermediate layer, a porosity of 70%, a pore size distribution of 120nm to 200nm, a thickness of 12 μm, and a solid polymer electrolyte 12 with a thickness of 0.5 μm coated on one side of the membrane ( The composition is PEO) and the solid polymer electrolyte 13 (the composition is PVDF) with a thickness of 0.8 μm on the other side; the ceramic ion conductor powder 14 with a particle size of 80 nm (the composition is Li 5 La 3 Ta 2 o 12 ) is anchored in the pores of the PET separator 11 through the binder PVDF, and the mass ratio of the ceramic ion conductor powder to the binder is 10:30.

[0063] 20nm inorganic particles 15 (composition of Li 7 La 3 Zr 2 o 12 ) Li 7 La 3 Zr 2 o 12 , the mass ratio of inorganic particles to solid polymer electrolyte is 97:30.

[0064] Its preparation method steps are as follows:

[0065] (1...

Embodiment 3

[0068] A composite solid electrolyte membrane with a sandwich structure, including a PI separator in the middle layer, with a porosity of 50%, a pore size distribution of 800nm to 1μm, a thickness of 20μm, and a solid polymer coated on both sides of the membrane with a thickness of 1μm respectively Electrolyte PPC; ceramic ionic conductor powder Li with a particle size of 200nm x La 2 / 3-x TiO 3 The binder PEO is anchored in the pores of the base film, and the mass ratio of the ceramic ion conductor powder to the binder is 100:30.

[0069] Its preparation method steps are as follows:

[0070] (1) Ceramic ion conductor powder and binder are dispersed in solvent acetonitrile to make slurry, ceramic ion conductor powder: binder: the mass ratio=100:30:80 of solvent, stir 100min to obtain slurry, slurry is coated with Cover both sides of the base film, then roll it, scrape off the excess slurry on both sides, and dry it in vacuum at 80°C for 13 hours to obtain the middle film l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com