Production method for factorized square fungi bag cultivation of Dictyophora rubrovolvata

The technology of a red-supported bamboo fungus and its production method, which is applied in the field of agricultural cultivation, can solve the problems of reducing the use of soil, reducing the demand for soil in the fruiting stage, and reducing the sterilization time, so as to reduce the use of soil and increase the inoculation area , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

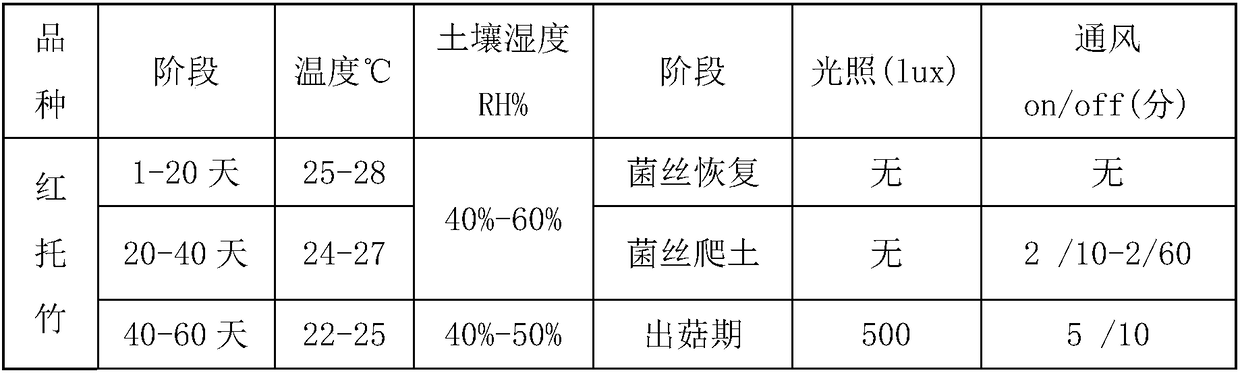

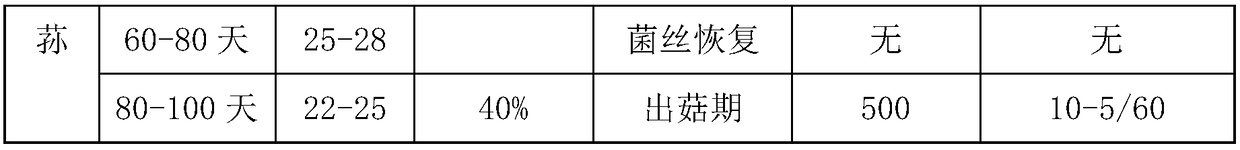

[0041] Embodiment 1 A kind of production method of factory-style square bag cultivation red-twisted bamboo fungus

[0042] (1) Recipe for square bacteria bag: by weight percentage, it is composed of 10% sawdust A, 30% sawdust B, 30% bagasse, 9% rice bran, 15%% bran, 5% corn flour, 1% lime powder, Sawdust A is pine wood less than 2mm, and sawdust B is 4-6mm hard miscellaneous wood chips, adjust the C / N to 25:1, and the water content is 62-64%;

[0043] (2) Use 20-24cm*12-16cm*50-60cm polypropylene plastic bag, and charge 2200g;

[0044] (3) Sterilize the bacteria package, the sterilization temperature is 121°C, and the sterilization time can be 2 hours by autoclaving. After the sterilization is completed, cool to room temperature. After the sterilization, the pH is 6.0, and inoculate 40g of solid bacteria. , spread on the surface of the square bacteria bag, the inoculation area is 600cm 2 (12cm*50cm);

[0045] (4) After the inoculation is completed, the temperature is 20° C....

Embodiment 2

[0053] The production method of embodiment 2 kinds of factory-style square bag cultivation red support bamboo fungus

[0054] (1) Recipe of square mushroom bag: by weight percentage, it is composed of 10% sawdust A, 30% sawdust B, 30% bagasse, 10% rice bran, 15% bran, 5% corn flour, 1% lime powder, sawdust A is pine wood below 2mm, sawdust B is 4-6mm hard miscellaneous wood chips, adjust the C / N to 30:1, and the water content is 62-64%;

[0055] (2) Use a 22cm*14cm*55cm polypropylene plastic bag, with a charge of 2700g;

[0056] (3) Sterilize the bacteria package, the sterilization temperature is 121°C, and the sterilization time can be 2 hours by autoclaving, after the sterilization is completed, cool to room temperature, the pH after sterilization is 6.3, and inoculate 50g of solid bacteria , spread on the surface of the square bacteria bag, the inoculation area is 600cm 2 (12cm*50cm);

[0057] (4) After the inoculation is completed, the temperature is 22° C. and the humi...

Embodiment 3

[0065] Embodiment 3 A kind of production method of factory-style square bag cultivation red-tucked Dictyophora

[0066] (1) Recipe of square mushroom bag: by weight percentage, it is composed of 20% sawdust A, 39% sawdust B, 20% bagasse, 5% rice bran, 15% bran, 5% corn flour, 1% lime powder, sawdust A is pine wood below 2mm, sawdust B is 4-6mm hard miscellaneous wood chips, adjust the C / N to 35:1, and the water content is 62-64%;

[0067] (2) Use a 24cm*16cm*60cm polypropylene plastic bag with a charge of 3200g;

[0068] (3) Sterilize the bacteria bag, the sterilization temperature is 121°C, and the sterilization time can be 2 hours by autoclaving, after the sterilization is completed, cool to room temperature, the pH after sterilization is 6.5, and inoculate 60g of solid bacteria , spread on the surface of the square bacteria bag, the inoculation area is 600cm 2 (12cm*50cm);

[0069] (4) After the inoculation is completed, the temperature is 25° C. and the humidity is 70% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com