Ganoderma powder preparation method

A technology of Ganoderma lucidum powder and Ganoderma lucidum, which is applied in the directions of medical preparations, pharmaceutical formulations, and plant raw materials containing active ingredients, can solve the problems of heavy metal pollution of Ganoderma lucidum powder and adverse human health, achieve unique physical and chemical properties, and improve bioavailability. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

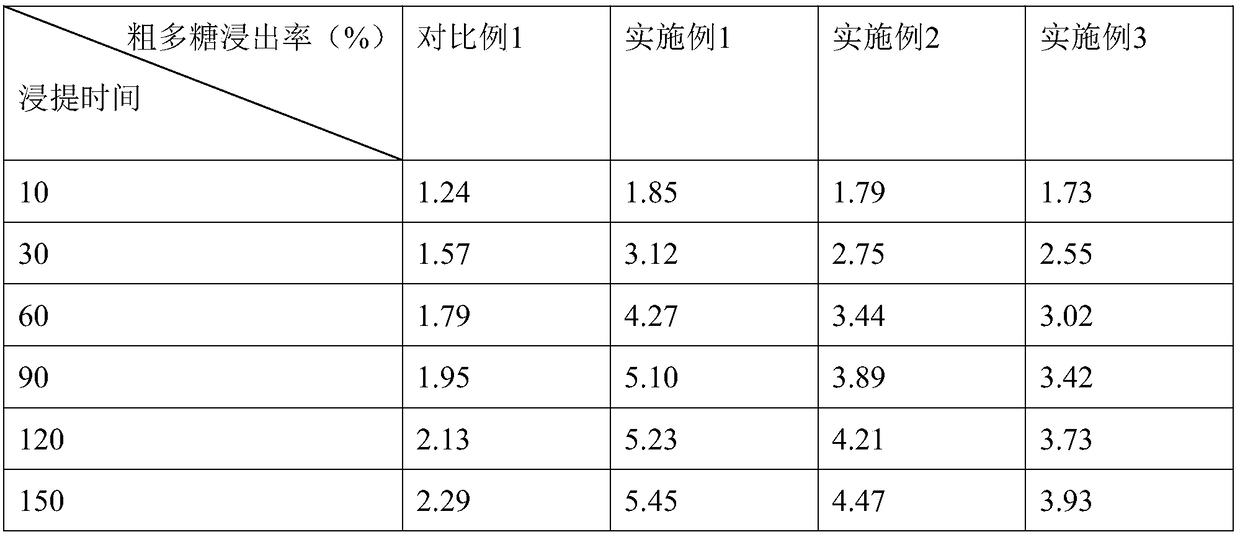

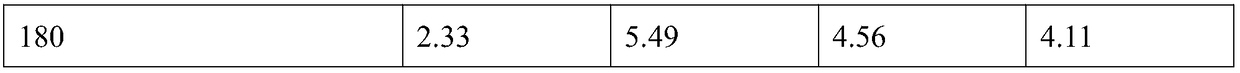

Embodiment 1

[0048] Embodiment 1: a kind of preparation method of Ganoderma lucidum powder, comprises the steps:

[0049] S1. Remove the handle of the purchased Ganoderma lucidum, and wash it with distilled water to remove impurities such as sediment. Slice the cleaned Ganoderma lucidum body, put it into a DZF-6050B vacuum drying oven with the temperature set at 40° C., and vacuum dry for 10 hours to obtain Ganoderma lucidum slices for use.

[0050] S2. Put the dried ganoderma lucidum slices into a FW35 Chinese herbal medicine pulverizer for pulverization. Pass the crushed Ganoderma lucidum powder through a 60-mesh sieve to obtain Ganoderma lucidum coarse powder.

[0051] S3. Lay the Ganoderma lucidum coarse powder on the filter paper, the thickness of which should be as small as possible, and put the filter paper in the tray provided with a hollow bottom. Use an atomizing humidifier to spray the Ganoderma lucidum powder with deionized water, soaked but dripping. The ganoderma lucidum p...

Embodiment 2

[0061] Embodiment 2: a kind of preparation method of Ganoderma lucidum powder

[0062] The difference with Embodiment 1 is that the parameters of using the BPQ-100 supersonic jet pulverizer in step S5 are as follows:

[0063] Batch injection volume: 4.8g; batch interval time: 1min; airflow crushing pressure: 0.7Mpa; spray flow rate: 500m / s;

[0064] Breaking temperature: 33°C

Embodiment 3

[0065] Embodiment 3: a kind of preparation method of Ganoderma lucidum powder

[0066] The difference with Embodiment 1 is that the parameters of using the BPQ-100 supersonic jet pulverizer in step S5 are as follows:

[0067] Batch injection volume: 4.5g; batch interval time: 1min; airflow crushing pressure: 0.8Mpa; ejection velocity: 450m / s;

[0068] Breaking temperature: 30°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com