Distillation and condensation device for strong acid and strong alkali

A distillation condensing device, strong acid and strong alkali technology, applied in steam condensation, distillation in boilers/distillates, chemical instruments and methods, etc., can solve problems such as inability to ensure sufficient condensation, inability to fully distill, low condensation efficiency, etc., to achieve The effect of improving the utilization rate of liquid material, sufficient heating and high distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

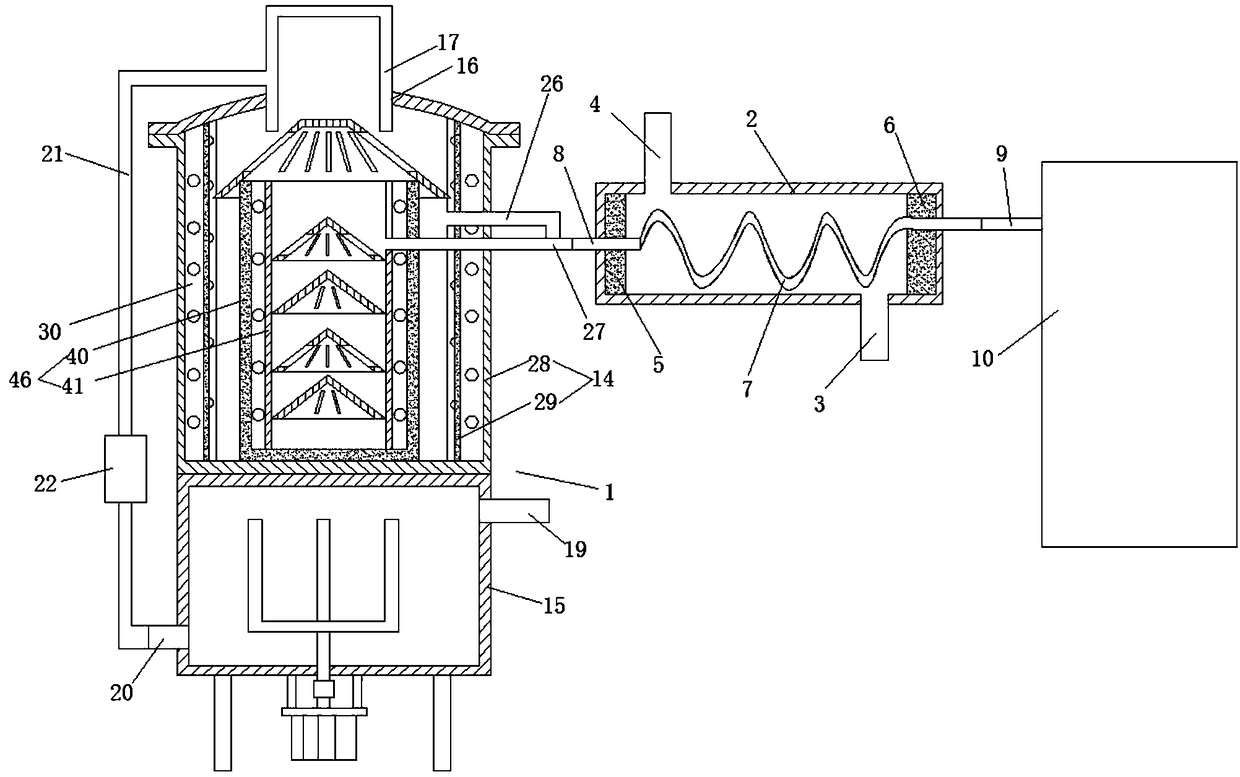

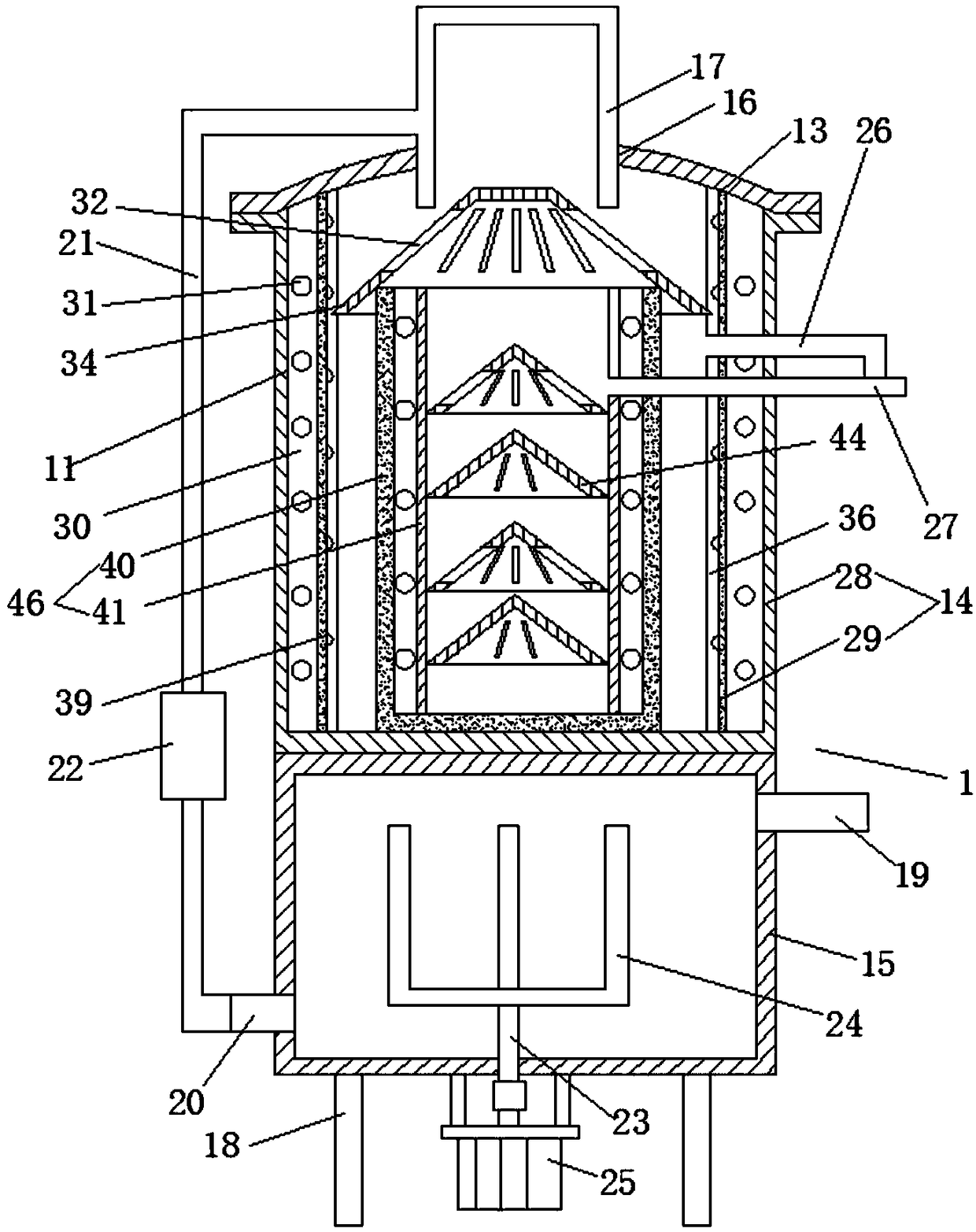

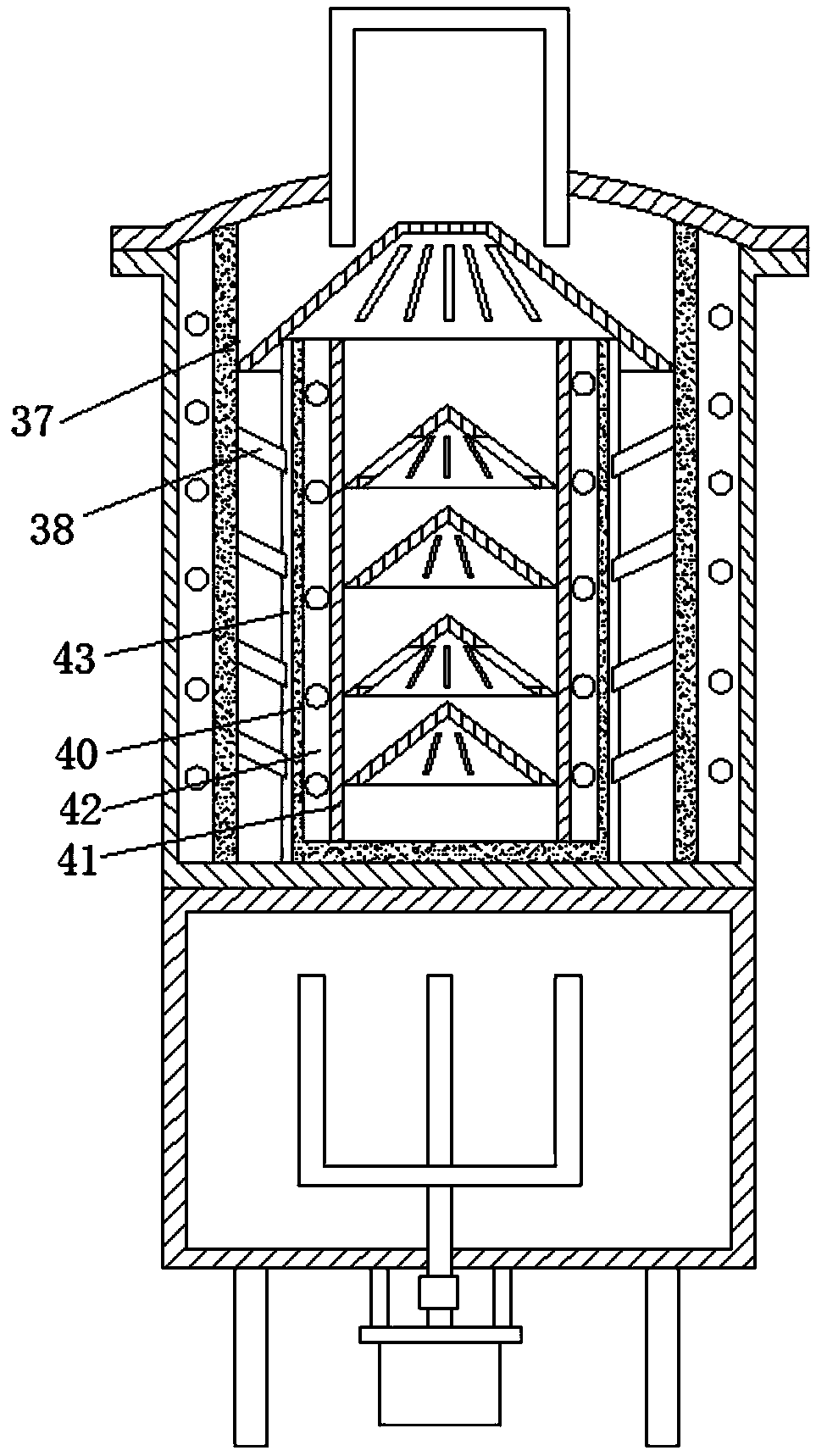

[0031] A distillation condensing device for strong acid and strong alkali, comprising a distillation reaction kettle 1, a condensation cylinder 2, and a cooling pipe;

[0032] Distillation reactor 1 comprises still body 11, still cover 13;

[0033] The kettle body 11 includes a main evaporating drum 14 and a mixing drum 15, the main evaporating drum 14 is located above the mixing drum 15, and the main evaporating drum 14 and the mixing drum 15 are connected to form an integrated structure; the upper surface of the main evaporating drum 14 is connected with the kettle cover 13, and the kettle cover 13 is provided with a feeding port 16, and the feeding port 16 is provided with a feeding pipe 17, and the feeding pipe 17 extends into the main evaporation cylinder 14, and the radius of the feeding pipe 17 is R1;

[0034] The bottom of the mixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com