Super-hydrophobic super-oleophylic nanofiber membrane used for oil-water mixture separation and preparation method thereof

A nanofiber membrane, oil-water mixture technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., to achieve the effect of improving oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the dry four-necked flask (mainly including mechanical stirrer, thermometer, N 2 Add 0.01 mol of BPDA and 0.01 mol of PDA to the tube) and mix evenly. Under vigorous mechanical stirring, 40ml of DMAc was added. Nitrogen gas was introduced to keep the ambient temperature at -5°C. After 12 hours of reaction, when the rod climbing phenomenon occurred, the reaction was terminated by exposing the reaction to air to obtain a PAA solution.

[0035] In order to obtain a polyimide (PI) film, it is first necessary to obtain a PAA film. The PAA solution was spun in a high-voltage electrostatic field with a voltage of 25kV (+15, -10kV). The distance from the needle tip to the flywheel was about 15cm. The electrospinning speed was 1mL / h, and it was collected with a grounded flywheel at a speed of 2000 rpm. PAA nanofibers. The polyamic acid fiber membrane (PAA film) obtained by electrospinning was heated to 150°C for 1h at a heating rate of 1°C / min, then heated to 200°C for 1h,...

Embodiment 2

[0037] (1) Cut the PI film into a sample of 2cm×2cm.

[0038] (2) Prepare polydimethylsiloxane (PDMS) solutions with five different concentrations (0.1wt%, 0.5wt%, 1wt%, 2wt%, 4wt%).

[0039] (3) After soaking the PI film sample in the PDMS solution for 2 hours, place it in a vacuum drying oven at 80° C. for 2 hours to obtain a PDMS / PI film.

[0040](4) Silica nanoparticle suspensions (SNPs) with five different concentrations (0.1wt%, 0.5wt%, 1wt%, 2wt%, 4wt%) were prepared.

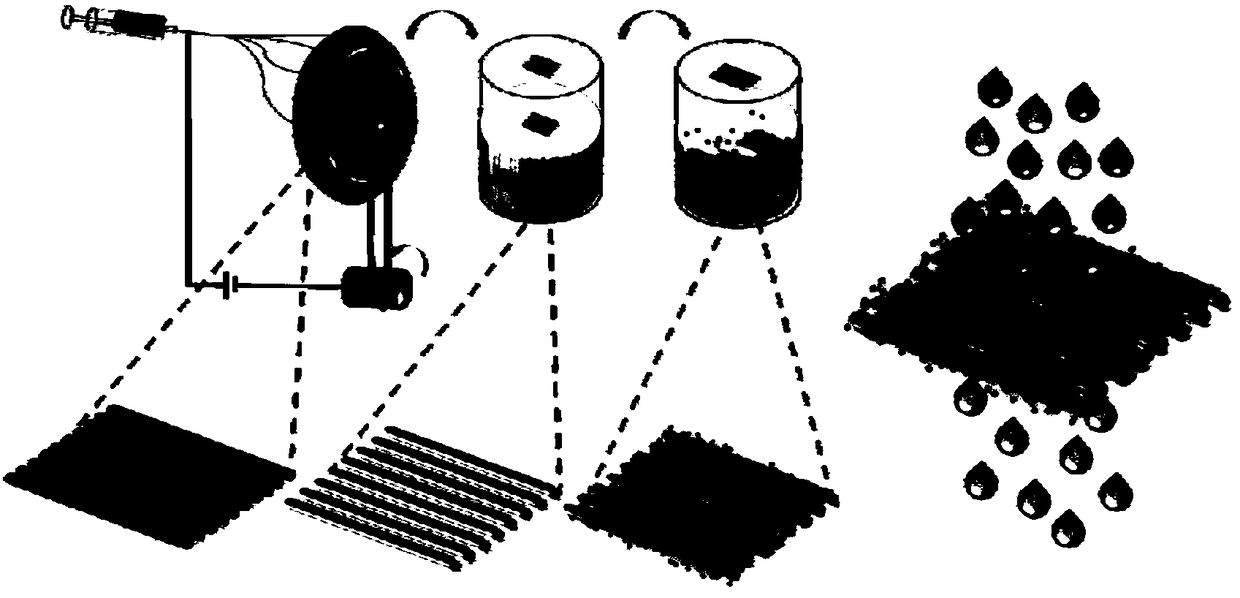

[0041] (5) Place the PDMS / PI film in the SNPs suspension for 2 hours, and then place it in a vacuum oven at 80°C for 2 hours to obtain the PDMS-SNPs / PI film. The whole process is as follows: figure 1 shown.

Embodiment 3

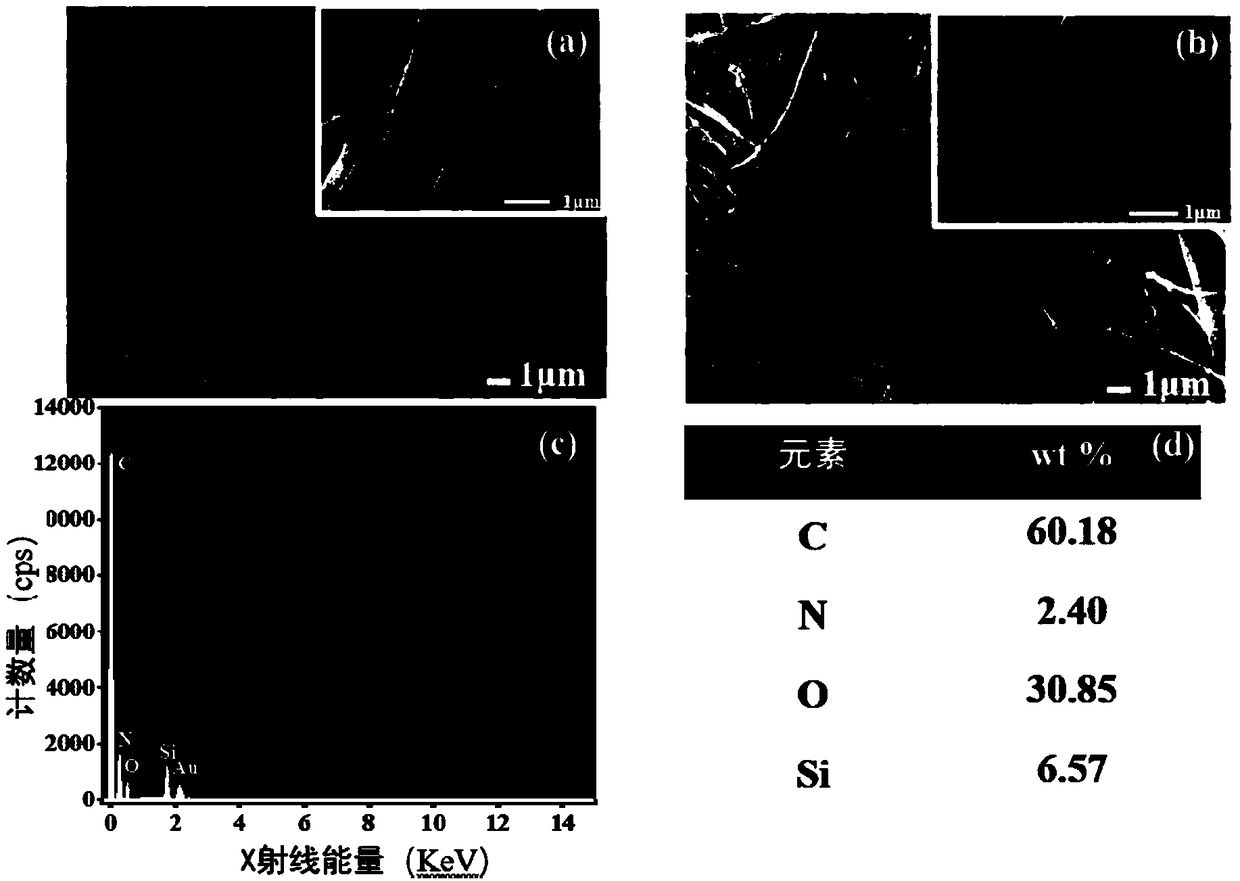

[0043] Using a field emission scanning electron microscope (S-4800, Japan Hitachi Electronics Co.), observe the surface morphology of the PDMS / PI film and PDMS-SNPs / PI film prepared in Example 2, which confirms that the film material prepared by the present invention has nano-roughness structure. The field emission scanning electron microscope used this time has the function of analyzing elements, and the elements on the surface of the membrane are confirmed through the equipped EDS analysis, which confirms the successful modification of the membrane, such as figure 2 shown.

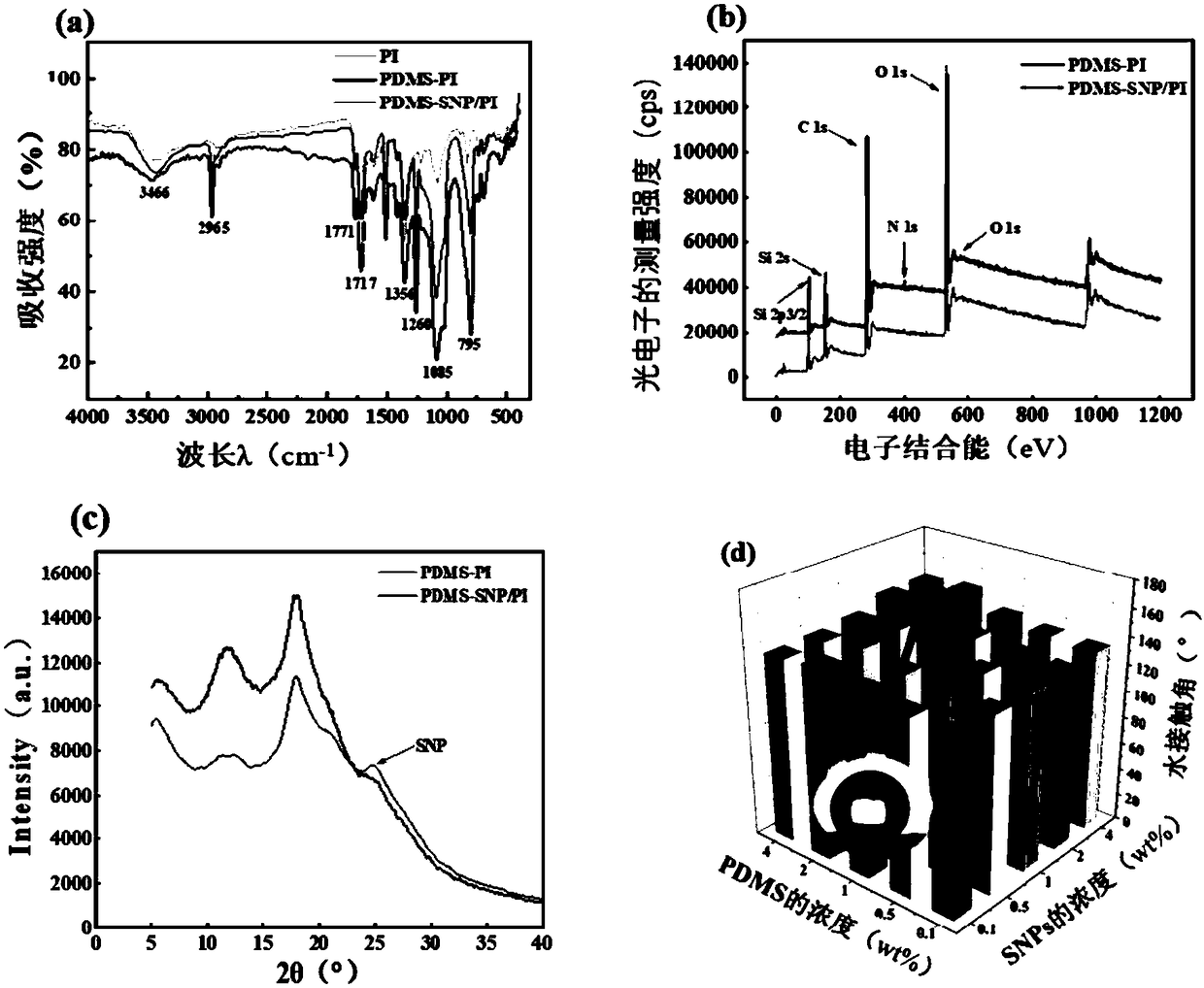

[0044] Adopt Nicolet 360FT-IR spectrometer to identify respectively the PI film that embodiment 1 prepares, the PDMS / PI film that embodiment 2 prepares, PDMS-SNPs / PI film functional group and film structure property, as image 3 as shown in a. One of the adsorption peaks of PI fiber is 1771cm -1 , can be attributed to the stretching vibration of the -CONH functional group, which proves that the imidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com