Argon shield welding device for titanium cup

An argon gas shielding and welding device technology, which is applied to devices for supplying/removing shielding gas, welding equipment, welding accessories, etc. The effect of improving quality and improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

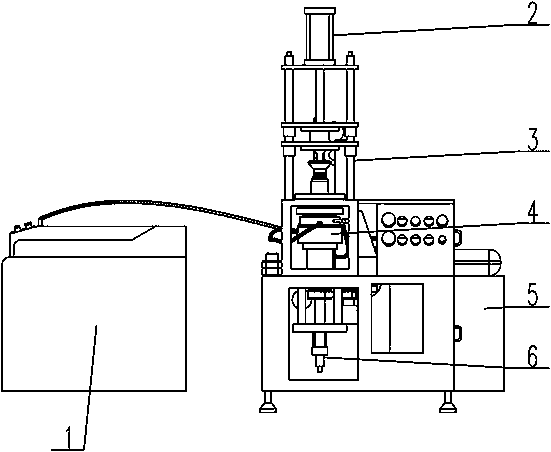

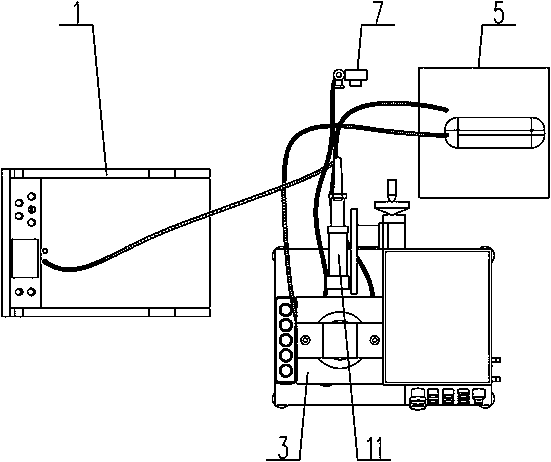

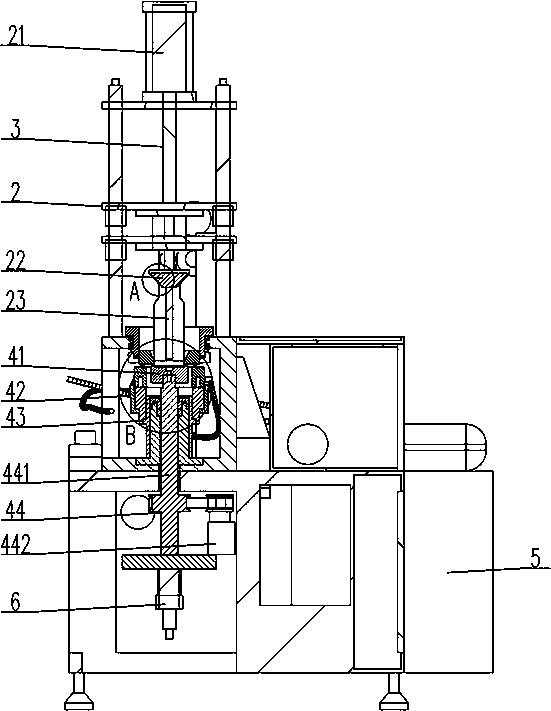

[0040] An argon-shielded welding device for a titanium cup includes a welding machine assembly 1, a frame 3, an argon transmission assembly 7, and a rotary positioning assembly. The rotary positioning assembly is arranged on the frame 3, and the welding The machine assembly 1 cooperates with the rotation positioning assembly, and the argon gas transmission assembly 7 is connected with the rotation positioning assembly.

[0041] When used, such as Figure 1 to Figure 3 As shown, first fix the cup body and bottom of the titanium cup to be processed on the rotary positioning assembly, then run the rotary positioning assembly to make the cup body and bottom of the titanium cup to be processed rotate at the same speed, and then start the welding machine assembly 1, The argon gas transmission component 7, the welding machine component 1 welds the cup body of the titanium cup to be processed and the weld seam of the cup bottom, and the welding machine component 1 converts the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com