Automatic sludge fuelization apparatus and method based on solar energy greenhouse

A technology for solar greenhouses and chemical devices, applied to fuels, solid fuels, biofuels, etc., can solve problems such as wasting energy, achieve the effects of reducing coal consumption, high calorific value of products, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

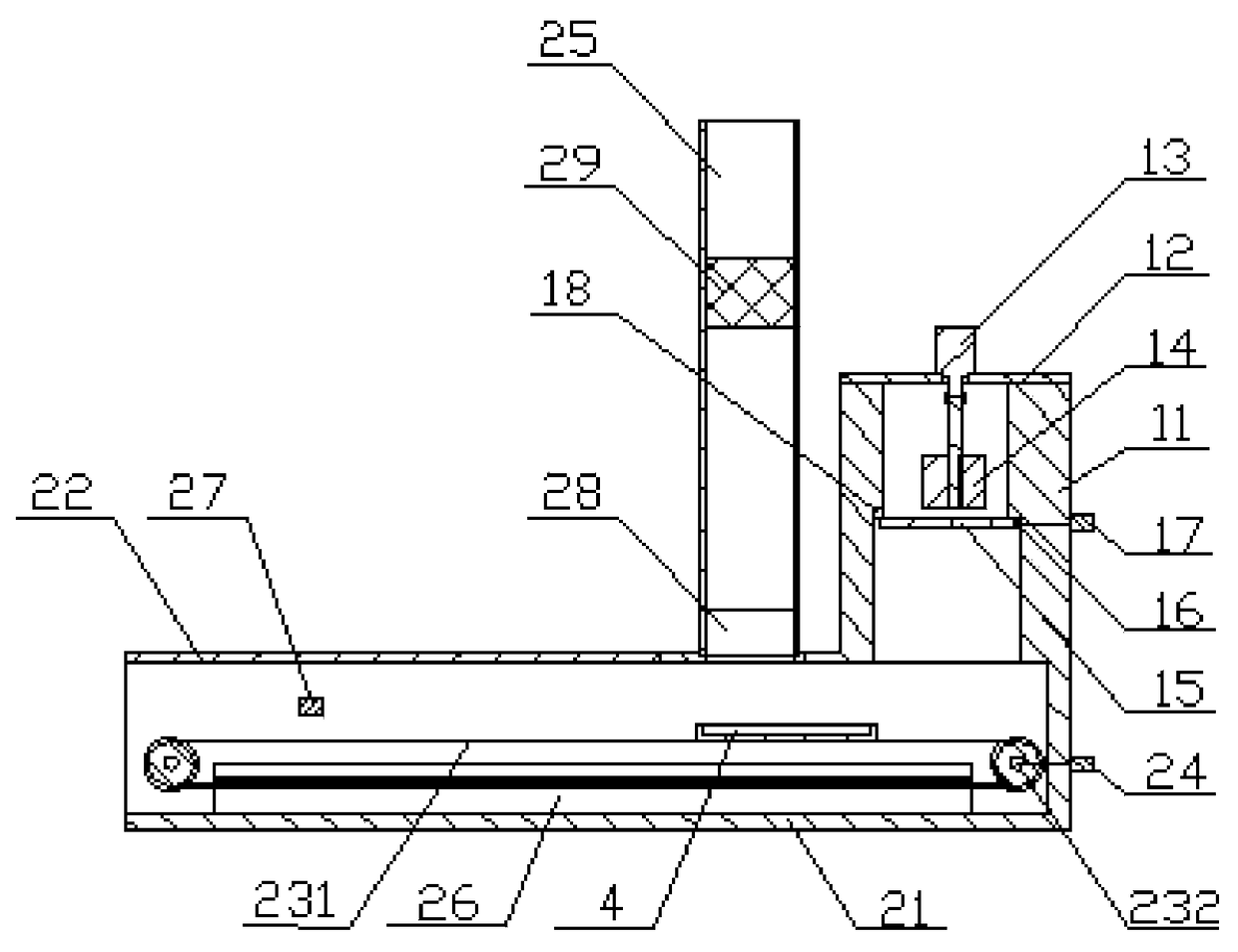

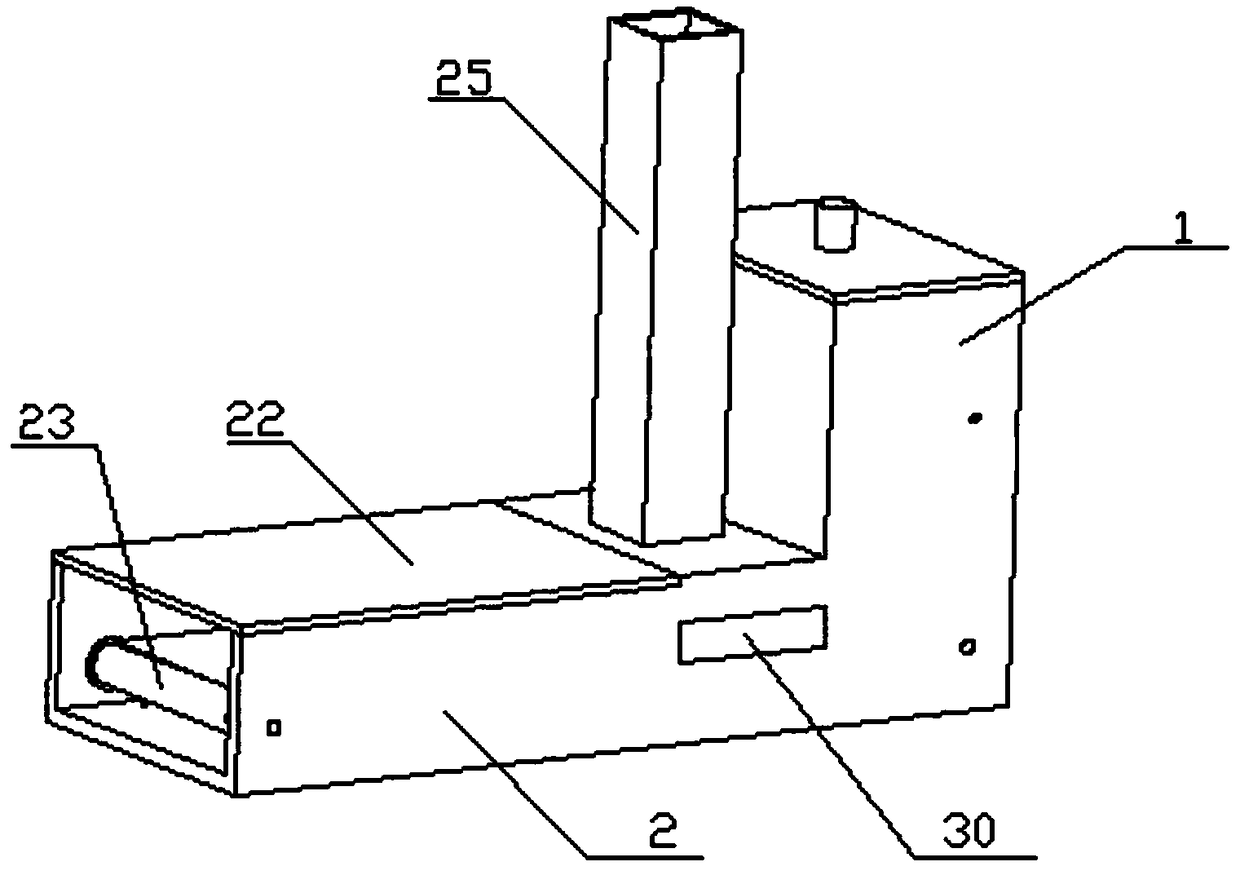

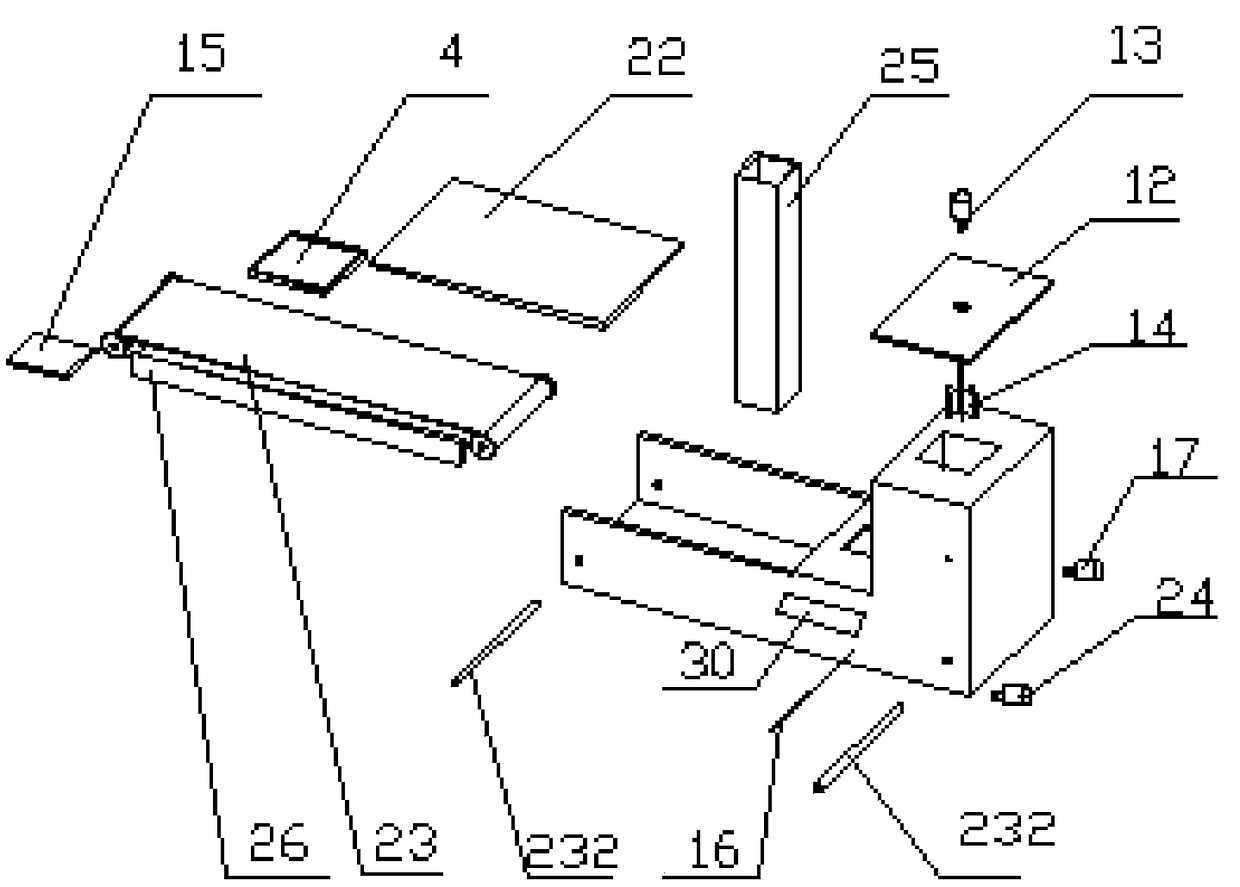

[0042] A sludge automatic fuelization device based on a solar greenhouse, comprising a pretreatment device 1, a drying device 2 and a control device 3, the pretreatment device 1 is arranged on the upper part of the drying device 2, the pretreatment device 1 and the The drying devices 2 are respectively connected with the control device 3 .

[0043]The pretreatment device 1 includes a housing I11, a cover plate 12, a motor I13, an agitator 14, a baffle plate 15, a baffle plate rotating shaft 16, a motor II17, and a relay 18; the upper part of the housing I11 is provided with a cover plate 12, so A motor I13 is installed on the cover plate 12, the motor I13 is electrically connected to the control device 3, the output shaft of the motor I13 passes through the central hole provided on the cover plate 12 and is connected to the agitator 14, and the agitator 14 A baffle 15 is arranged below, and the baffle 15 is rotatably connected to the inner wall of one side of the housing I11 t...

Embodiment 2

[0047] A sludge automatic fuelization device based on a solar greenhouse, comprising a pretreatment device 1, a drying device 2 and a control device 3, the pretreatment device 1 is arranged on the upper part of the drying device 2, the pretreatment device 1 and the The drying devices 2 are respectively connected with the control device 3 .

[0048] The pretreatment device 1 includes a housing I11, a cover plate 12, a motor I13, an agitator 14, a baffle plate 15, a baffle plate rotating shaft 16, a motor II17, and a relay 18; the upper part of the housing I11 is provided with a cover plate 12, so A motor I13 is installed on the cover plate 12, the motor I13 is electrically connected to the control device 3, the output shaft of the motor I13 passes through the central hole provided on the cover plate 12 and is connected to the agitator 14, and the agitator 14 A baffle 15 is arranged below, and the baffle 15 is rotatably connected to the inner wall of one side of the housing I11 ...

Embodiment 3

[0052] A sludge automatic fuelization device based on a solar greenhouse, comprising a pretreatment device 1, a drying device 2 and a control device 3, the pretreatment device 1 is arranged on the upper part of the drying device 2, the pretreatment device 1 and the The drying devices 2 are respectively connected with the control device 3 .

[0053] The pretreatment device 1 includes a housing I11, a cover plate 12, a motor I13, an agitator 14, a baffle plate 15, a baffle plate rotating shaft 16, a motor II17, and a relay 18; the upper part of the housing I11 is provided with a cover plate 12, so A motor I13 is installed on the cover plate 12, the motor I13 is electrically connected to the control device 3, the output shaft of the motor I13 passes through the central hole provided on the cover plate 12 and is connected to the agitator 14, and the agitator 14 A baffle 15 is arranged below, and the baffle 15 is rotatably connected to the inner wall of one side of the housing I11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com