High-performance self-heating material as well as reaction apparatus and application method thereof

A reaction device and self-heating technology, applied in the direction of heat exchange materials, chemical instruments and methods, food heating containers, etc., can solve the problems of slow start-up speed, no initiator, fast reaction speed, etc., to prevent moisture and spray The effect of out and leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

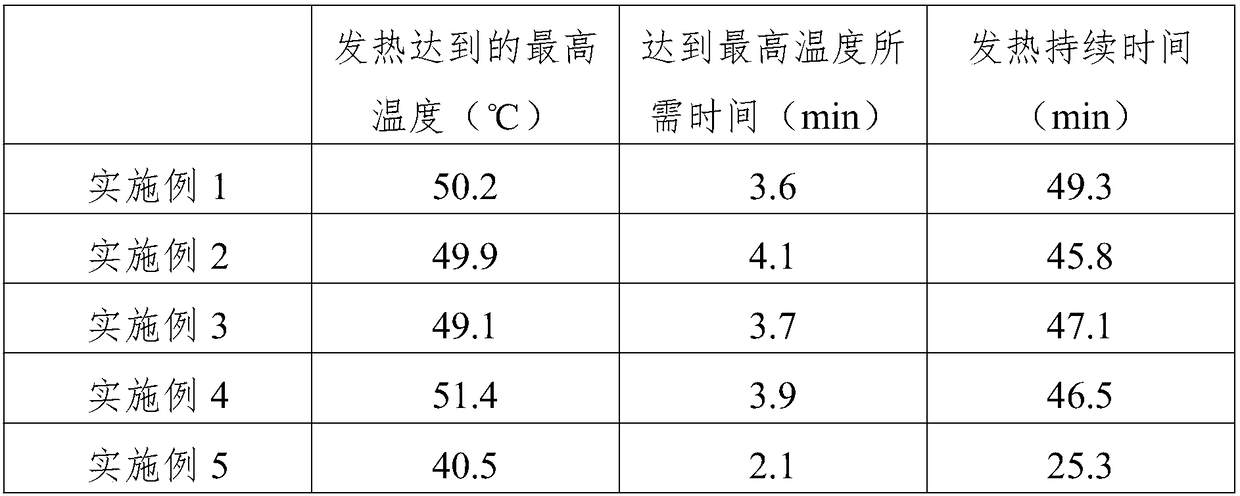

Examples

Embodiment 1

[0041] This embodiment provides a high-efficiency self-heating material, which is prepared from the following raw materials in grams by weight: 20 grams of calcium oxide, 1.5 grams of aluminum powder, 5 grams of sodium carbonate, 0.15 grams of aluminum chloride, activated carbon Powder 0.2 grams, water 22 grams.

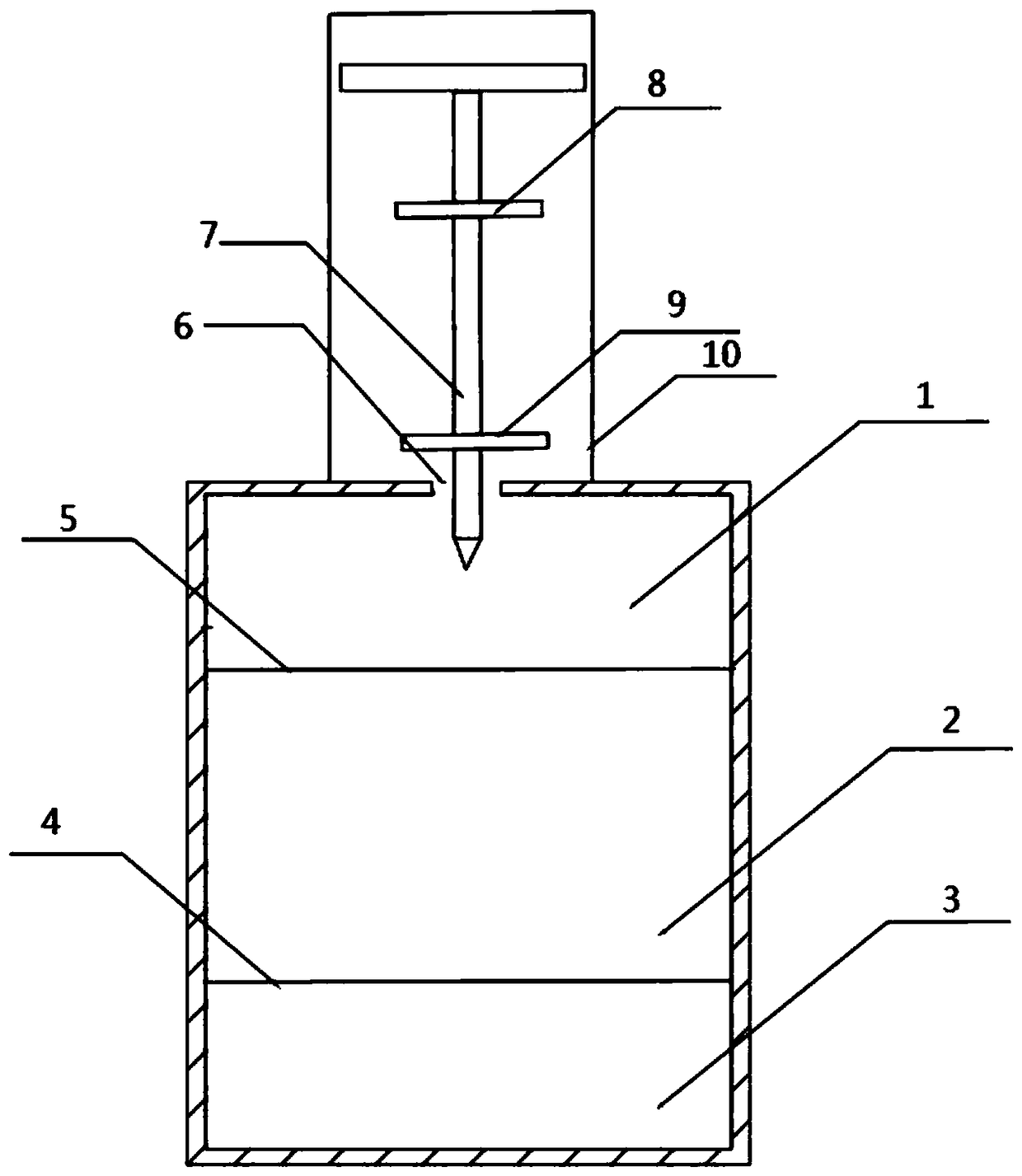

[0042] Such as figure 1 As stated above, the reaction device for the above-mentioned high-efficiency self-heating material includes a water storage chamber 1, a first exothermic reaction chamber 2, and a second exothermic reaction chamber 3 arranged sequentially from top to bottom; A first airtight barrier 5 between the chamber and the first exothermic reaction chamber, a second airtight barrier 4 disposed between the first exothermic reaction chamber and the second exothermic reaction chamber;

[0043] Described reaction device also comprises the reaction device hole 6 that is arranged on the reaction device top wall, inserts 7, and described intubation part enters...

Embodiment 2

[0051] This embodiment provides a high-efficiency self-heating material, which is prepared from the following raw materials in grams by weight: 16 grams of calcium oxide, 2 grams of aluminum powder, 3 grams of sodium carbonate, 0.2 grams of aluminum chloride, activated carbon Powder 0.1 gram, water 35 grams.

[0052] The insertion tube of the above-mentioned high-efficiency self-heating material reaction device includes a second buckle 8 and a first buckle 9 arranged sequentially from top to bottom, and the second buckle and the first buckle are removably arranged on the insertion on the fittings.

[0053] Other content is identical with embodiment 1.

Embodiment 3

[0055] This embodiment provides a high-efficiency self-heating material, which is prepared from the following raw materials in grams by weight: 25 grams of calcium oxide, 1 gram of aluminum powder, 8 grams of sodium carbonate, 0.1 gram of aluminum chloride, activated carbon Powder 0.3 grams, water 10 grams.

[0056] The reaction device of the above-mentioned high-efficiency self-heating material also includes an insert shell 10, which is removably arranged on the outside of the insert for protecting the insert.

[0057] Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com