Titanium alloy plate and processing method thereof

A processing method and technology of titanium alloy, applied in the field of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

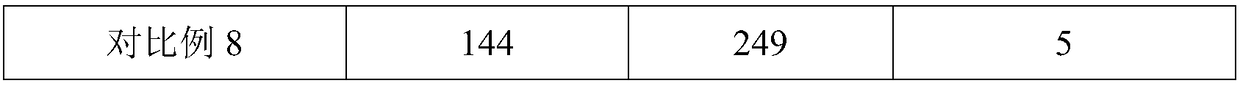

Examples

Embodiment 1

[0026] A titanium alloy plate, comprising the following raw materials: Ti: 100 parts, Al: 4 parts; V: 3 parts; Fe: 0.5 parts, silver fluoride 0.05 parts, silicone 0.03 parts, zirconia fiber 0.02 parts;

[0027] A processing method according to the above-mentioned titanium alloy plate, comprising the following steps: (1) preparing alloy raw materials according to the titanium alloy composition; (2) pressing them into electrodes after mixing the materials, and heating them in a vacuum consumable electric arc furnace at 900°C Melt and cast for 30 minutes at low temperature, add silver fluoride, zirconia fiber and silicone after cooling down to 450°C, keep warm for 30 minutes, then gradually increase the temperature to 800°C and continue to melt and cast for 30 minutes to obtain alloy ingots; (3) peeling and cutting of ingots After removing the riser and tail end, the slab is made into a slab through forging and repeated pier drawing to refine the structure; (4) hot rolling the sla...

Embodiment 2

[0029] A titanium alloy plate, comprising the following raw materials: Ti: 100 parts, Al: 5 parts; V: 2 parts; Fe: 1.0 parts, silver fluoride 0.04 parts, silicone 0.04 parts, zirconia fiber 0.01 parts;

[0030]A processing method according to the above-mentioned titanium alloy plate, comprising the following steps: (1) preparing alloy raw materials according to the titanium alloy composition; (2) pressing them into electrodes after mixing the materials, and heating them in a vacuum consumable electric arc furnace at 900°C Melt and cast for 20 minutes under low temperature, add silver fluoride, zirconia fiber and silicone after cooling down to 500°C, keep warm for 30 minutes, gradually increase the temperature to 800°C and continue to melt and cast for 30 minutes to obtain alloy ingots; (3) peeling and cutting of ingots After the riser and tail end are removed, the slab is made into a slab through blank forging and repeated pier drawing to refine the structure; (4) hot rolling t...

Embodiment 3

[0032] A titanium alloy plate, comprising the following raw materials: Ti: 100 parts, Al: 3 parts; V: 4 parts; Fe: 0.2 parts, silver fluoride 0.06 parts, silicone 0.02 parts, zirconia fiber 0.03 parts;

[0033] A processing method according to the above-mentioned titanium alloy plate, comprising the following steps: (1) preparing alloy raw materials according to the titanium alloy composition; (2) pressing them into electrodes after mixing the materials, and heating them in a vacuum consumable electric arc furnace at 900°C Melt and cast for 40 minutes under low temperature, add silver fluoride, zirconia fiber and silicone after cooling down to 400°C, keep warm for 30 minutes, gradually increase the temperature to 800°C and continue to melt and cast for 30 minutes to obtain alloy ingots; (3) Ingot peeling, cutting After the riser and tail end are removed, the slab is made into a slab through blank forging and repeated pier drawing to refine the structure; (4) hot rolling the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com