Film coating equipment and method

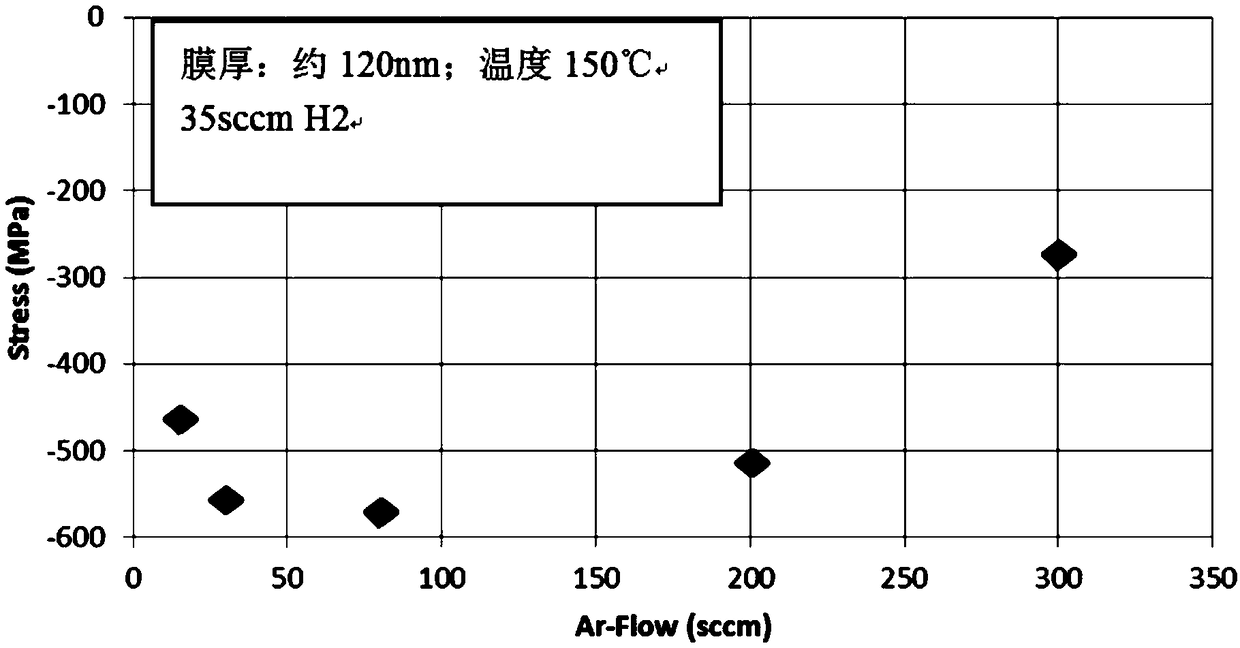

A coating equipment and band-pass film technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of low production efficiency of optical filters, and achieve the improvement of product stress, stable internal structure, Evenly attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

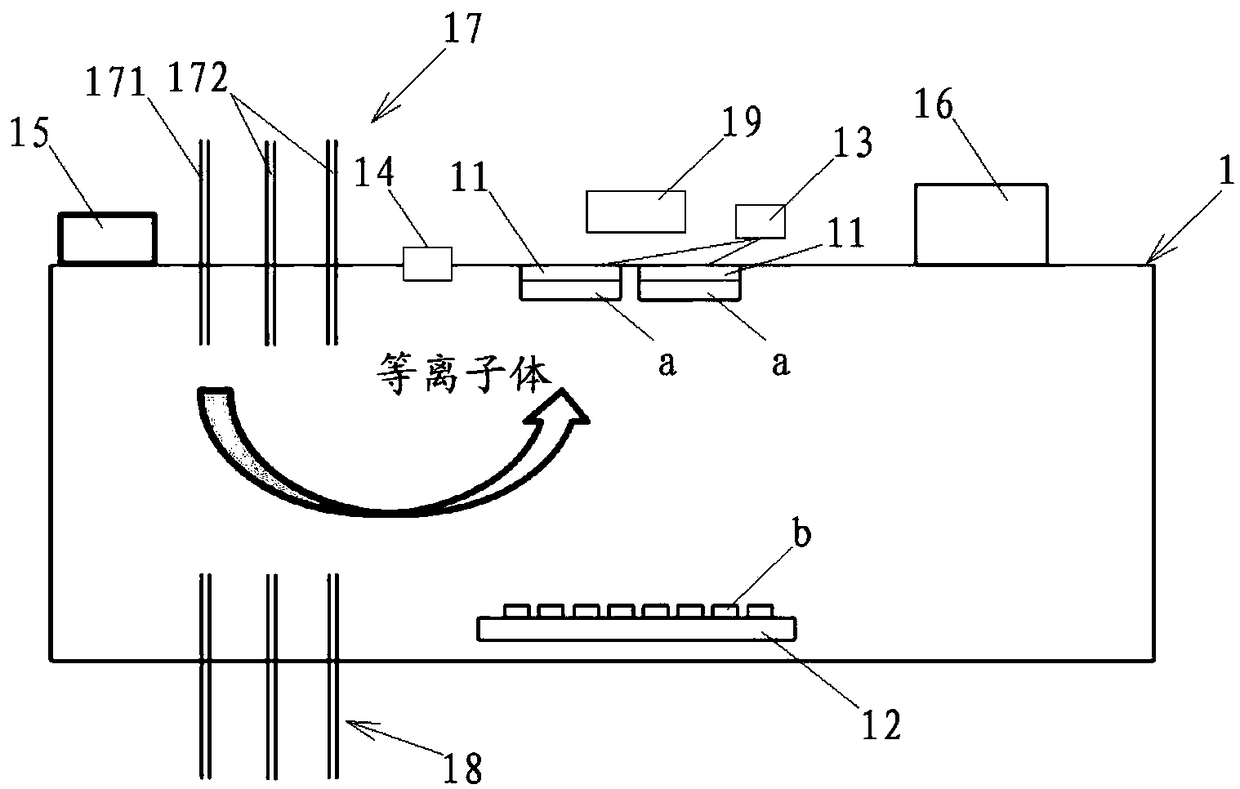

[0045] According to one embodiment of the present invention, a kind of coating method of the present invention comprises:

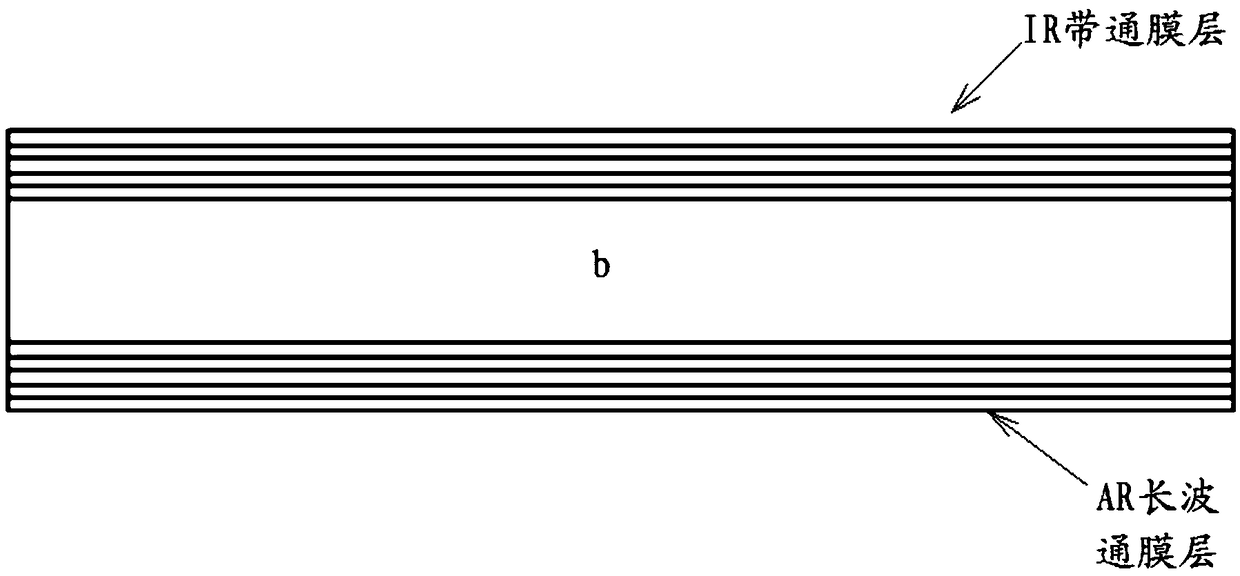

[0046] S1. Install the sputtering target a and the substrate b in the vacuum chamber 1 respectively, and control the pressure in the vacuum chamber 1 to a preset pressure value. In this embodiment, the sputtering target a is installed on the target base 11 in the vacuum chamber 1. In this embodiment, the sputtering target a can be a silicon target or a niobium target, and of course it can also be Other materials, depending on the specific situation. The substrate b to be coated with a film layer is installed on the base fixture 12 . The position of the target base 11 is adjusted by controlling the linear displacement device on the target base 11 . Turn on the power supply of the pumping device 16, pump the vacuum chamber 1 through the pumping device 16, make the pressure value in the vacuum chamber 1 reach the preset pressure value, and stop the operati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com