Wear-resistant and oil stain-proof book cover packing paper

A book cover paper and anti-oil technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of book protection, difficulty in folding, poor durability, etc., achieve enhanced adsorption and antibacterial effects, prevent oil and water penetration, enhance The effect of the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

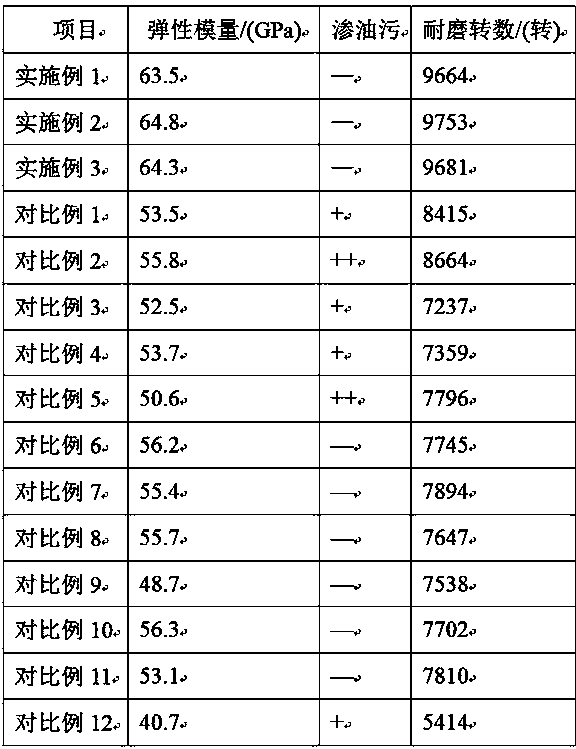

Examples

Embodiment 1

[0017] Disclosed is a wear-resistant, oil- and stain-resistant book cover paper, which includes an outer protective layer and an inner folded layer.

[0018] The protective layer is composed of the following raw materials in parts by weight: natural latex 28, epoxy resin modified styrene-acrylic emulsion 17, nano-titanium dioxide 3.2, nano-alumina 2.1, negative ion powder 0.5.

[0019] The folded layer is composed of the following raw materials in parts by weight: paper fiber 41 , cotton fiber 17 , bamboo fiber 14 , and activated carbon fiber 6 .

[0020] A method for preparing a wear-resistant, oil- and stain-resistant book cover paper, comprising the following steps:

[0021] (1) Preparation of folded layer: Put paper fiber, cotton fiber, bamboo fiber and activated carbon fiber in water to make the folded layer soft and comfortable, easy to fold, and resistant to tearing. At the same time, the addition of bamboo fiber and activated carbon fiber can enhance the adsorption and...

Embodiment 2

[0026] Disclosed is a wear-resistant, oil- and stain-resistant book cover paper, which includes an outer protective layer and an inner folded layer.

[0027] The protective layer is composed of the following raw materials in parts by weight: natural latex 29, epoxy resin modified styrene-acrylic emulsion 18, nano-titanium dioxide 3.3, nano-alumina 2.2, negative ion powder 0.6.

[0028] The folded layer is composed of the following raw materials in parts by weight: paper fiber 42, cotton fiber 18, bamboo fiber 15, activated carbon fiber 7.

[0029] A method for preparing a wear-resistant, oil- and stain-resistant book cover paper, comprising the following steps:

[0030] (1) Preparation of folded layer: Put paper fiber, cotton fiber, bamboo fiber and activated carbon fiber in water to make the folded layer soft and comfortable, easy to fold, and resistant to tearing. At the same time, the addition of bamboo fiber and activated carbon fiber can enhance the adsorption and Antiba...

Embodiment 3

[0035] Disclosed is a wear-resistant, oil- and stain-resistant book cover paper, which includes an outer protective layer and an inner folded layer.

[0036] The protective layer is composed of the following raw materials in parts by weight: natural latex 30, epoxy resin modified styrene-acrylic emulsion 19, nano-titanium dioxide 3.4, nano-alumina 2.3, negative ion powder 0.7.

[0037] The folded layer is composed of the following raw materials in parts by weight: paper fiber 43, cotton fiber 19, bamboo fiber 16, activated carbon fiber 8.

[0038] A method for preparing a wear-resistant, oil- and stain-resistant book cover paper, comprising the following steps:

[0039] (1) Preparation of folded layer: Put paper fiber, cotton fiber, bamboo fiber and activated carbon fiber in water to make the folded layer soft and comfortable, easy to fold, and resistant to tearing. At the same time, the addition of bamboo fiber and activated carbon fiber can enhance the adsorption and Antiba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com