Complex environment simulation test system for ballastless track of high-speed railway

A simulation test system and ballastless track technology, which is applied in the field of high-speed railway ballastless track complex environment simulation test system, can solve the problems of high-speed railway operating conditions and climate differences, and achieve simple and intuitive operation and monitoring, convenient maintenance, and structural layout. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

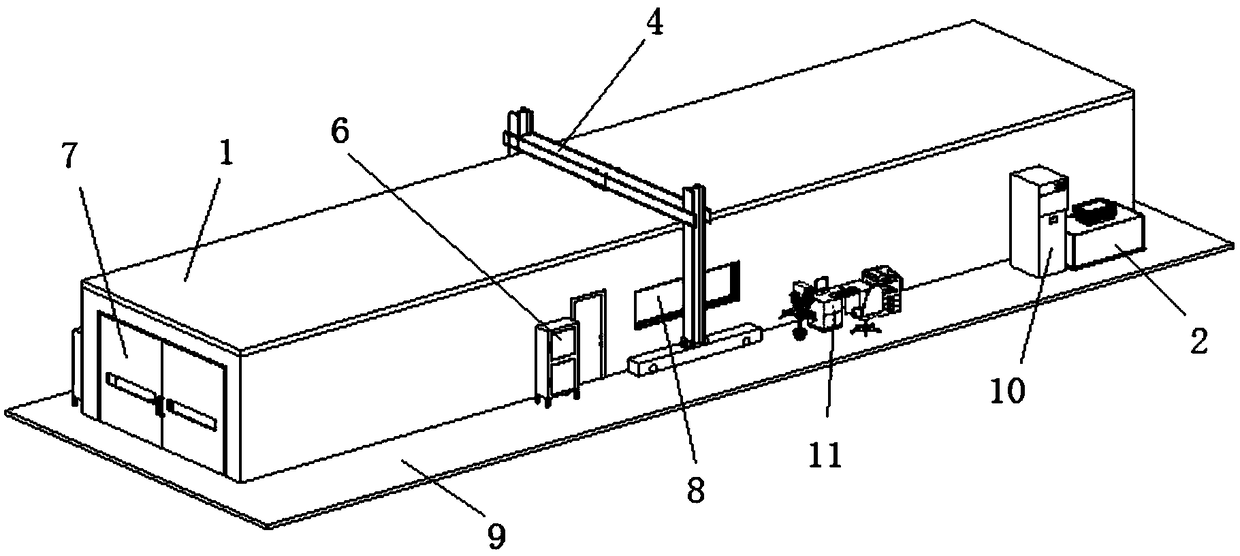

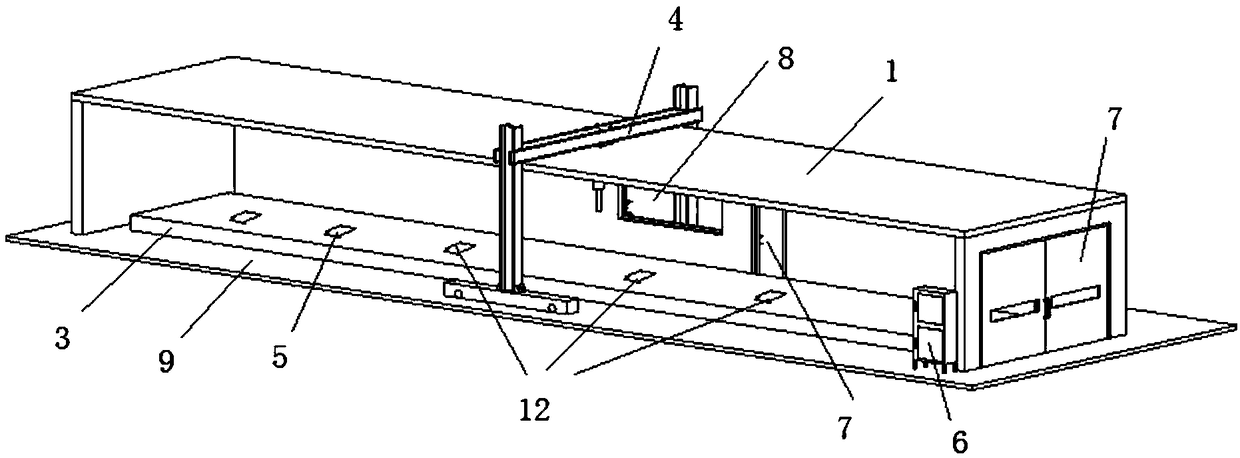

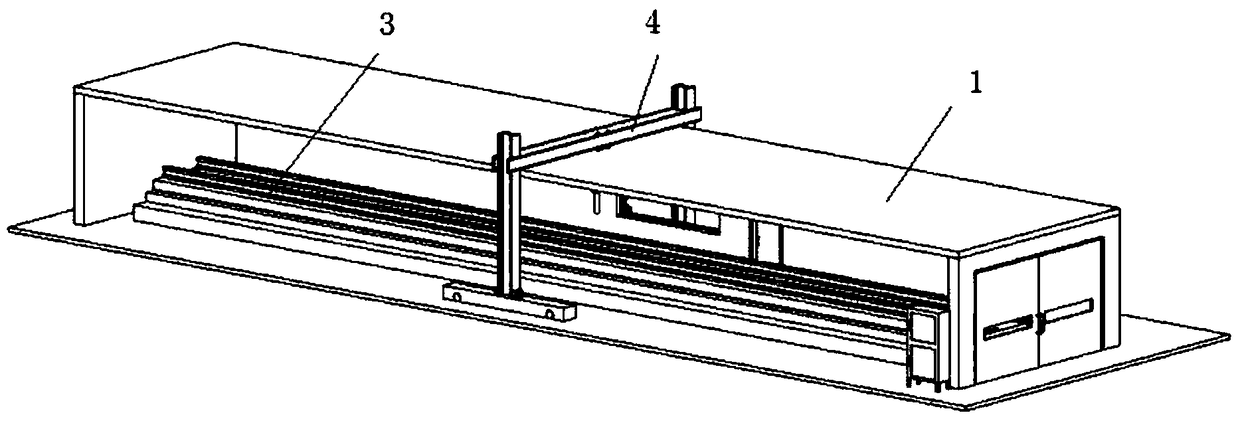

[0068] see figure 1 as well as figure 2 , image 3 The high-speed railway ballastless track complex environment simulation test system provided by Embodiment 1 of the present invention includes a test platform storage body 1, a large walk-in temperature and humidity control system 2, a slab ballastless track structure 3, and a mobile prototype fatigue test loader System 4;

[0069] Wherein: the test platform storage body 1 includes a storage body body surrounded by a plurality of storage body surfaces, a gate 7 and an observation window 8 arranged on the side of the storage body body, and a ventilation device arranged at the bottom of the storage body body body and test platform base 9;

[0070] The large-scale walk-in temperature and humidity control system 2 is arranged on the side wall of the test platform library body 1; the large-scale walk-in temperature and humidity control system 2 is used to raise the temperature of the air in the test platform library body 1 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com