Photoacoustic endoscope for high-precision three-dimensional scanning of front micro motor and imaging method

A micro-motor and three-dimensional scanning technology, applied in endoscopy, medical science, sensors, etc., can solve problems that are not suitable for endoscopic imaging, and achieve the effects of small overall size, reduced noise, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

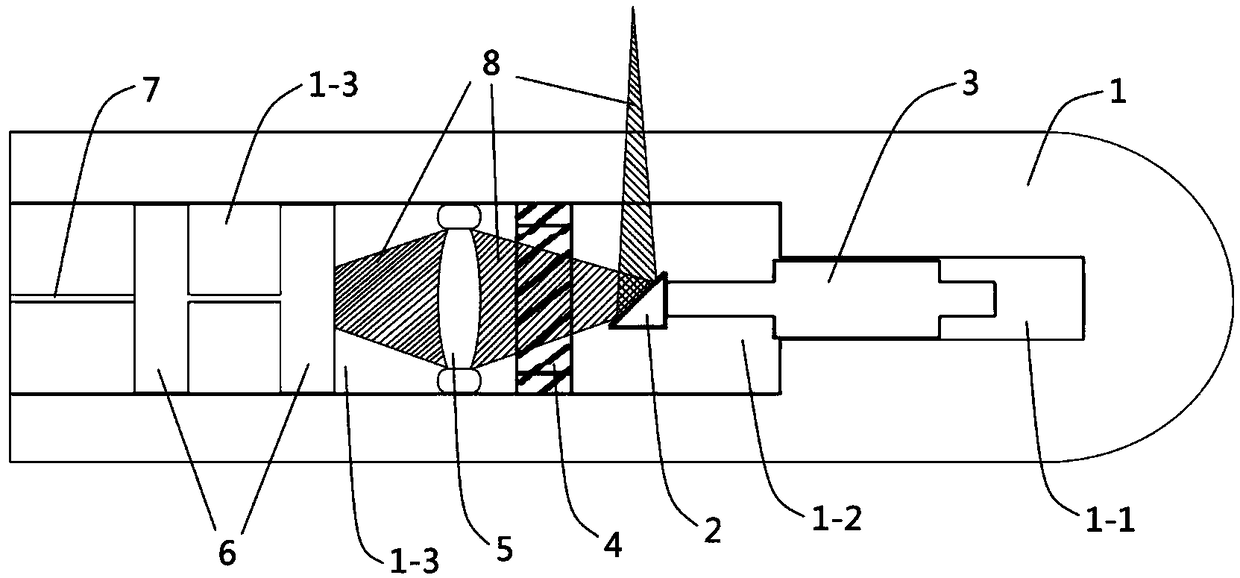

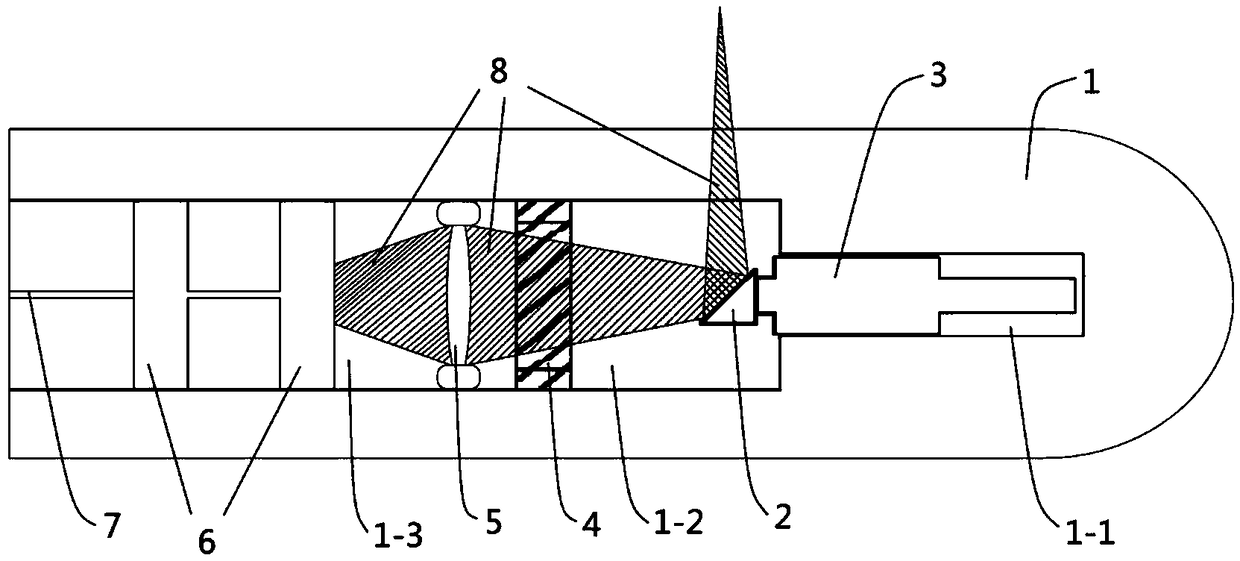

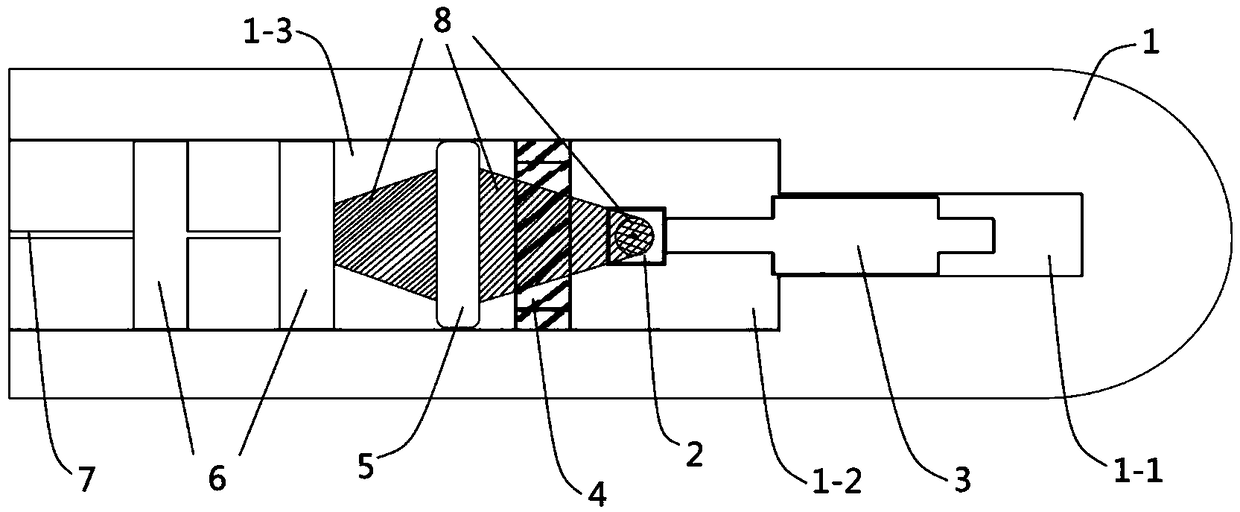

[0035] Such as figure 1 , figure 2 and image 3As shown, a photoacoustic endoscope with high-precision pre-three-dimensional scanning includes a probe shell 1, a micro-motor placement cavity 1-1, an oil chamber 1-2, a cavity 1-3, an optical reflection prism 2, and a micro-motor 3. Ultrasonic transducer 4. Optical zoom lens 5. Optical fiber bearing 6. Optical fiber 7. Laser beam 8.

[0036] The inside of the probe shell 1 is provided with a micro-motor placement chamber 1-1, an oil chamber 1-2 and a cavity 1-3, the micro-motor placement chamber is arranged at the front end of the probe case, and the oil chamber is arranged at the probe The middle position inside the shell, the cavity is arranged at the tail end inside the probe shell.

[0037] The ultrasonic transducer 4 is installed in the middle of the probe shell 1 to separate the oil chamber 1-2 from the cavity 1-3; The main part of the motor 3 is fixed on the micro-motor placement chamber 1-1 at the top of the probe s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com