Slurry stirring device for spinning assembly line

A stirring device and assembly line technology, applied to mixers with rotating stirring devices, mixer accessories, drive agitator dissolution, etc., can solve problems such as insufficient dye mixing, affecting use effect and practical performance, poor coloring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

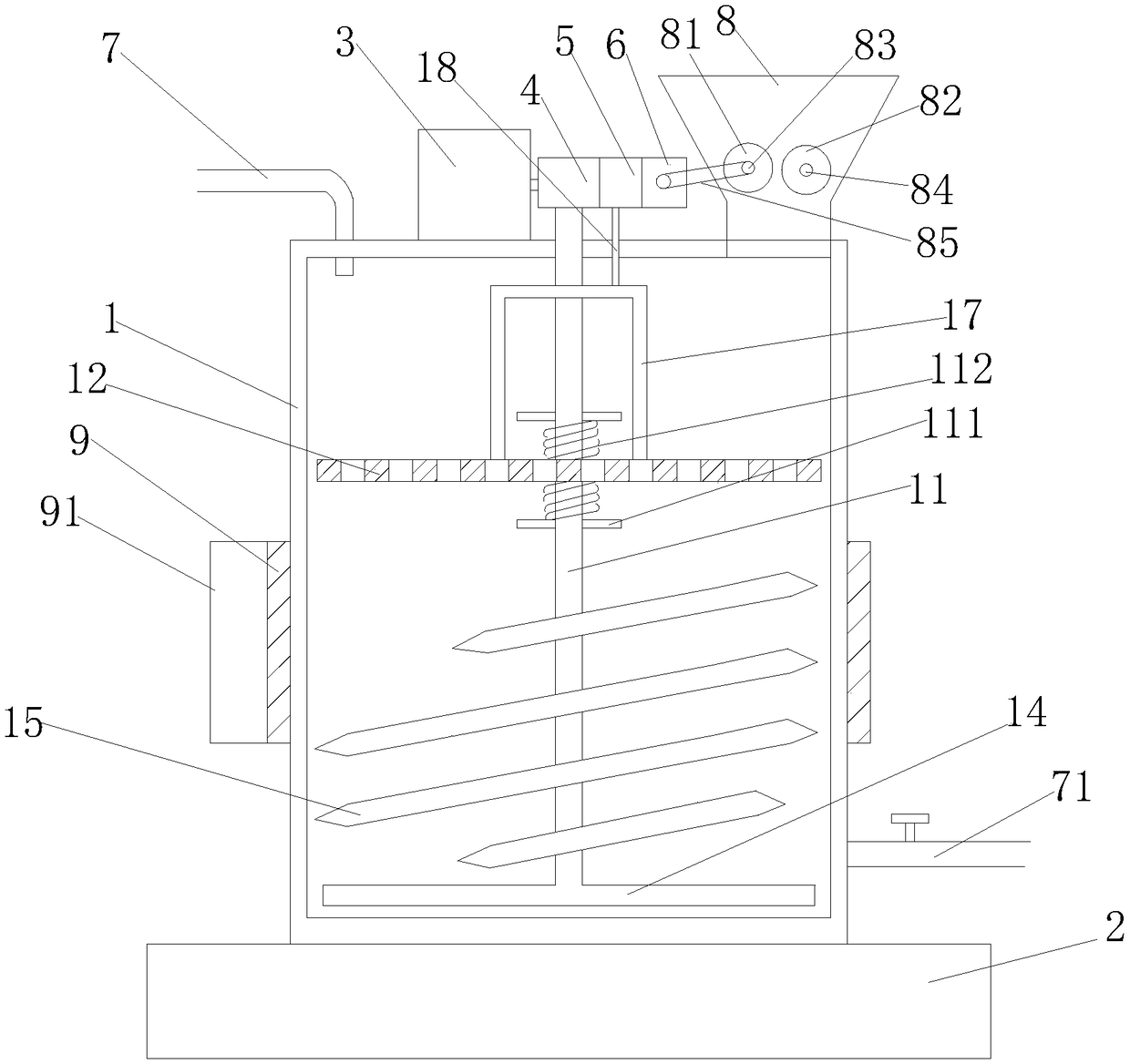

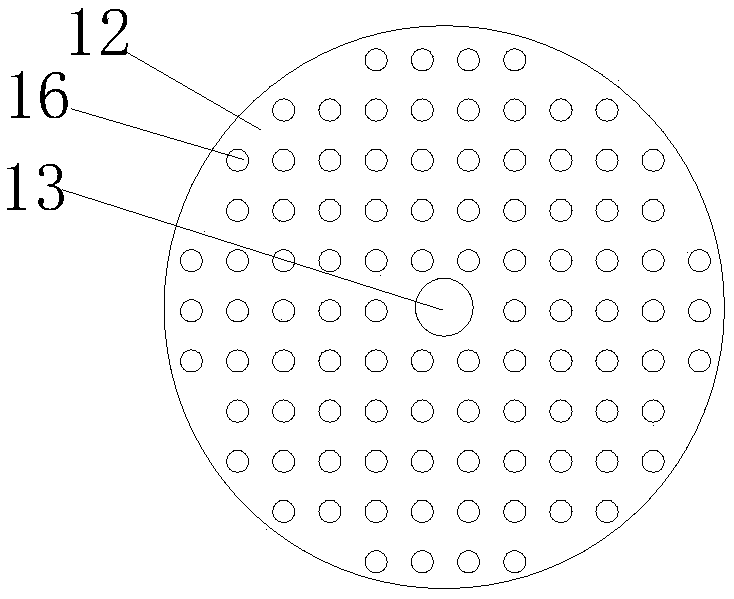

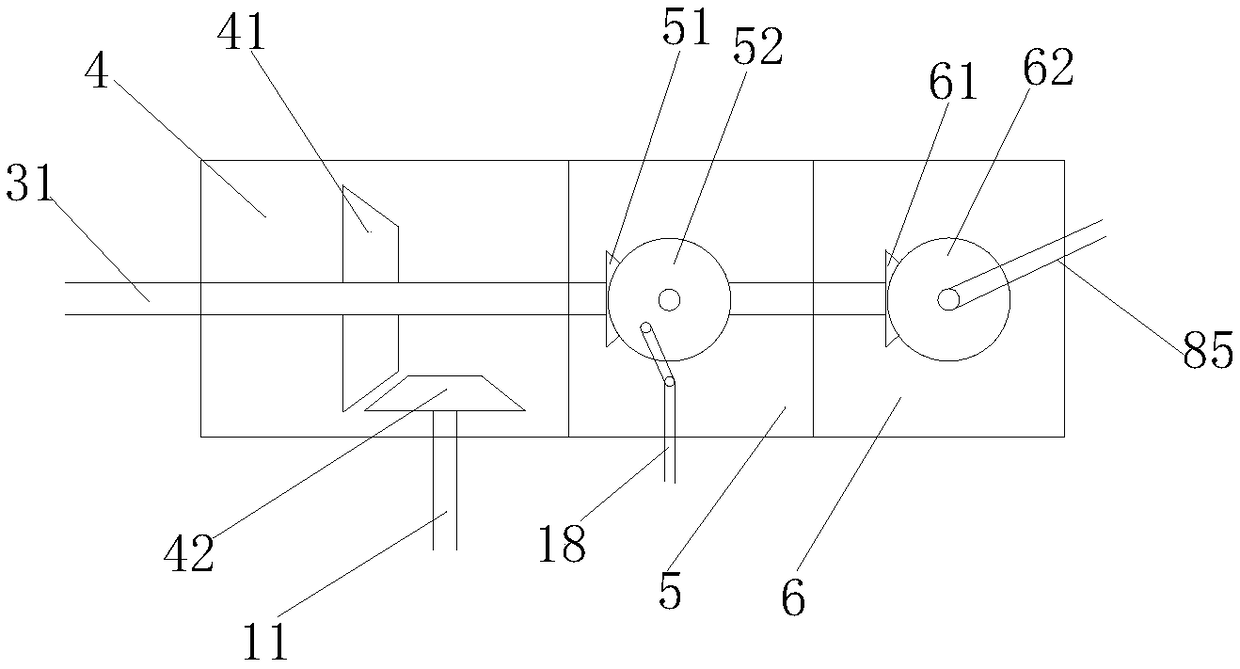

[0022] Such as figure 1 Shown: a slurry mixing device for a textile assembly line, including a cylindrical mixing drum 1 and a base 2, the mixing drum 1 is installed on the base 2, and a motor 3 is installed on the upper side of the mixing drum 1, and the motor 3. Through the rotating shaft 31, it is respectively connected with the gearbox I4, the gearbox II5 and the gearbox III6. The inside of the mixing drum 1 is provided with a stirring shaft 11 and a partition 12, and the center of the upper side wall of the mixing drum 1 is provided with Shaft hole I, the central part of the partition plate 12 is provided with a shaft hole II 13, the upper end of the stirring shaft 11 passes through the shaft hole I and is matched with the transmission of the gearbox I 4, and the middle part of the stirring shaft 11 passes through the shaft hole II 13, the lower end of the stirring shaft 11 is provided with a scraper 14, the center of the scraper 14 is welded vertically to the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com