Liquid nitrogen flow intelligent regulating, controlling and cooling system suitable for low-temperature cutting

A cooling system and low-temperature technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of excessive liquid nitrogen flow, liquid nitrogen waste, low liquid nitrogen flow and difficult cooling effect, etc., to achieve Improve the degree of automation, improve the surface quality of the workpiece, and reduce the effect of tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

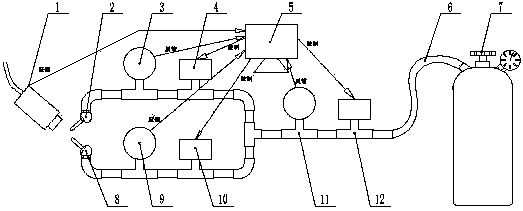

[0022] Such as figure 1 shown. The system sequentially includes an infrared thermometer (1), an upper pipeline steering nozzle (2), an upper pipeline low temperature flowmeter (3), an upper pipeline low temperature electric valve (4), a central processing unit (5), a transportation pipe Road (6), liquid nitrogen tank (7), lower pipeline steering nozzle (8), lower pipeline cryogenic flowmeter (9), lower pipeline low temperature electric valve (10), main pipeline cryogenic flowmeter (11), The main pipeline low temperature electric valve (12). The infrared thermometer (1) is responsible for detecting the temperature of the rake face and the flank face in real time and feeding it back to the central processing unit (5). According to the set reasonable temperature, the central processing unit (5) first adjusts the liquid nitrogen flow in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com