Wet transferring method of graphene

A wet transfer and graphene technology, applied in the field of graphene, can solve problems such as wrinkles, incomplete removal of protective layer, and residual impurities on the surface of graphene, so as to prevent cracks and wrinkles, achieve no impurity pollution, and high-quality transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

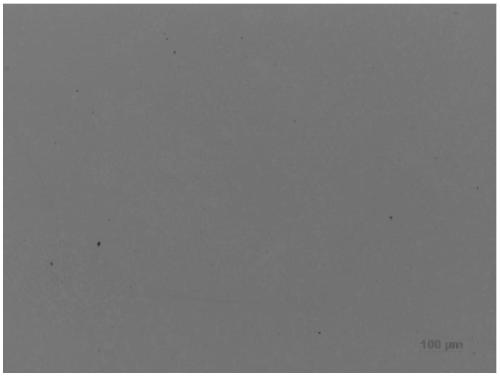

Examples

Embodiment 1

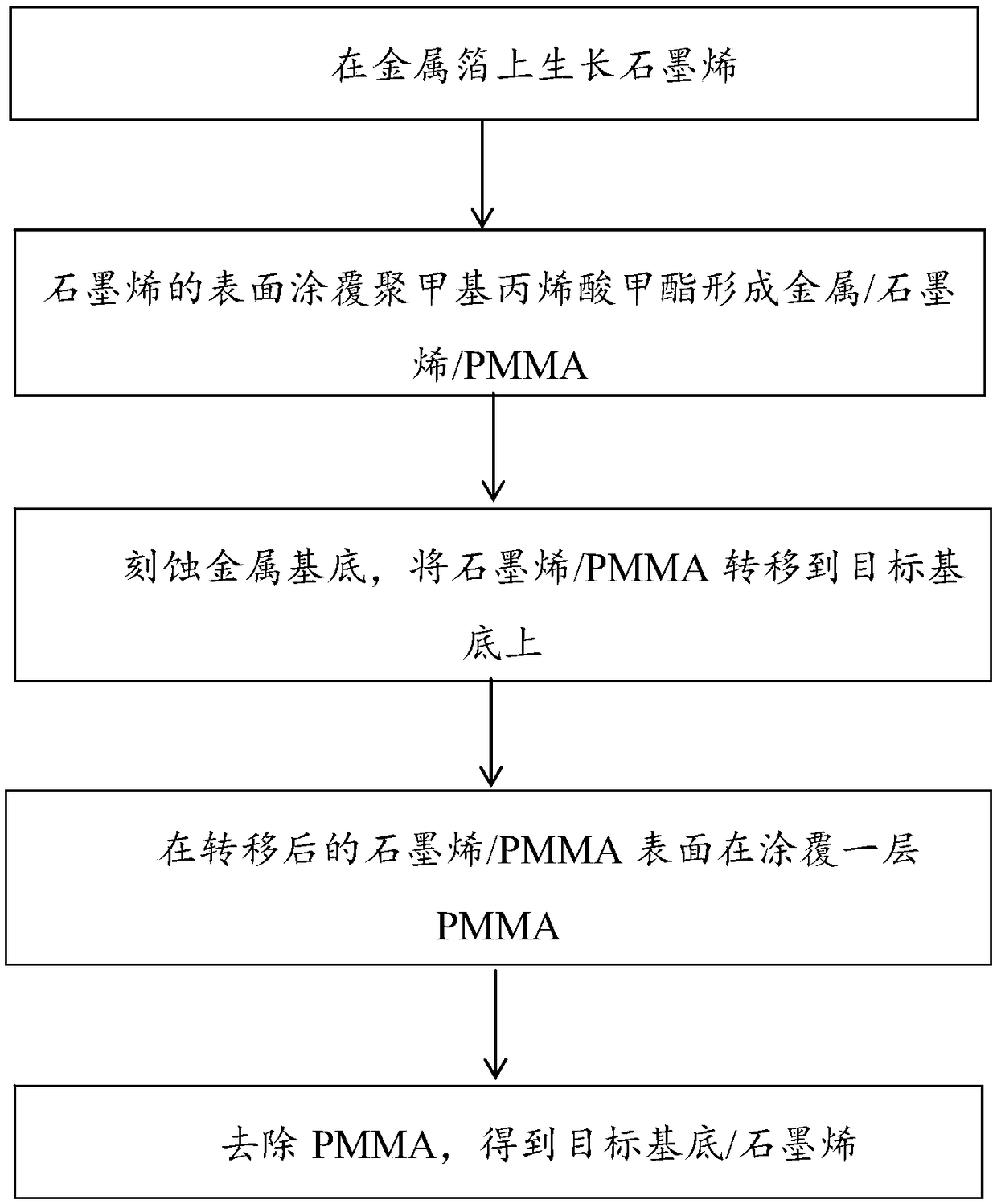

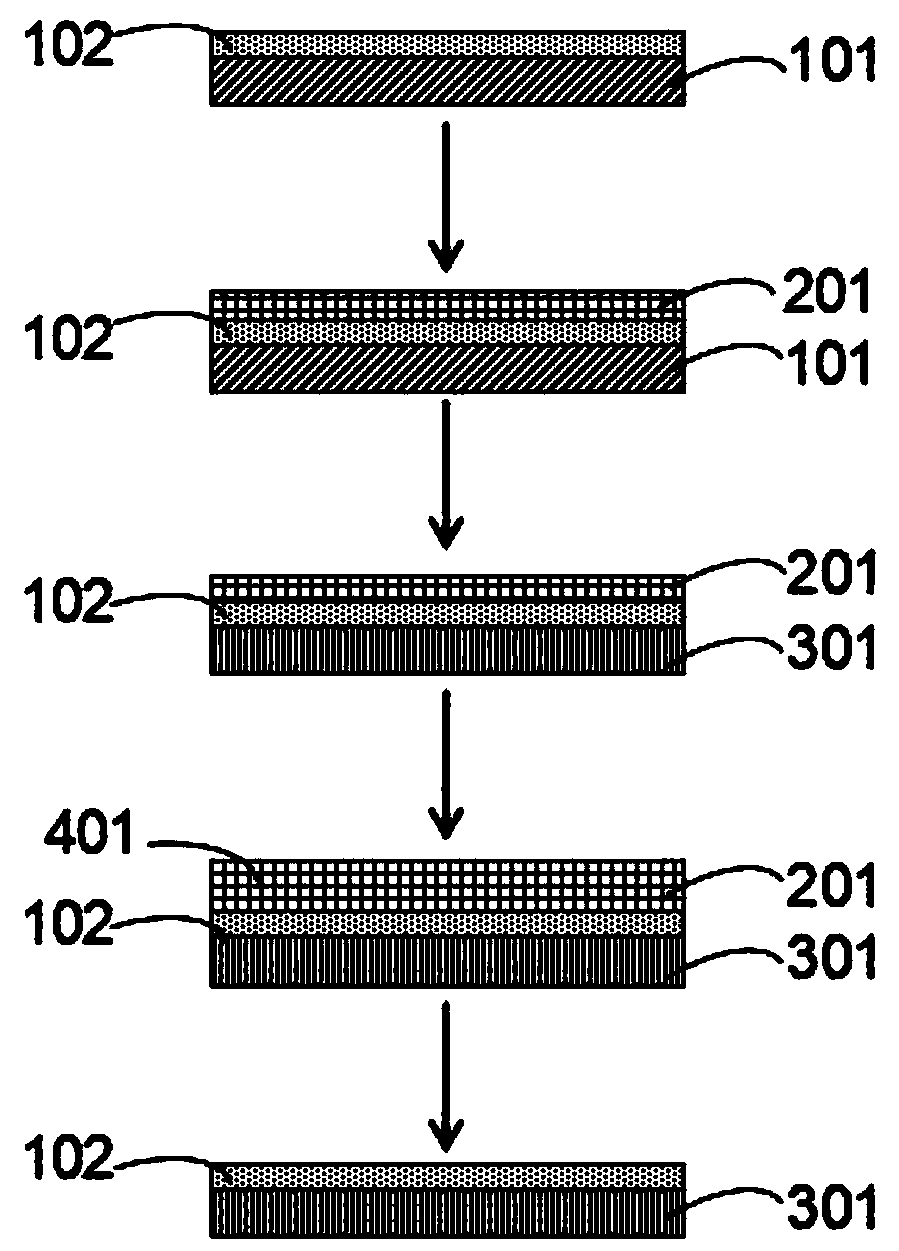

[0038] A kind of method of wet transfer graphene of the present embodiment, comprises the steps:

[0039] (1) Cut a piece of 10mm×10mm copper foil with graphene, and fix it on the surface of a square glass sheet with adhesive tape. The purpose is to ensure that the graphene film is flat. On the turntable, start the vacuum pump and homogenizer, set the low speed to 30rd / min, rotate for 3s, and the high speed to 3000rd / min, rotate for 20s, use a syringe to draw PMMA with a mass fraction of 0.4%, choose anisole as the solvent, and drop evenly on the On the surface of the copper foil, then quickly cover the lid, start the spin coating, and form copper / graphene / PMMA;

[0040] (2) Remove the spin-coated PMMA copper foil and cure it for 10 minutes at a temperature of 150°C;

[0041] (3) Grind the side of the graphene copper foil that is not spin-coated with PMMA with fine sandpaper, put it into a 0.1mol / L ammonium persulfate solution to etch the copper foil, and use a clean glass pi...

Embodiment 2

[0046] A kind of method of wet transfer graphene of the present embodiment, comprises the steps:

[0047] (1) Cut a piece of 20mm×20mm copper foil with graphene, and fix it on the surface of a square glass sheet with adhesive tape. The purpose is to ensure that the graphene film is flat. On the turntable, start the vacuum pump and the homogenizer, set the low speed to 10rd / min, rotate for 10s, and the high speed to 1500rd / min, rotate for 60s, use a syringe to absorb PMMA with a mass fraction of 2.2%, choose acetone as the solvent, and evenly drop it on the copper foil on the surface, then quickly put the lid on, start the spin coating, and form copper / graphene / PMMA;

[0048] (2) Remove the spin-coated PMMA copper foil and cure it for 180min at a temperature of 120°C;

[0049] (3) Polish the side of the graphene copper foil that is not spin-coated with PMMA with fine sandpaper, put it into a 0.5mol / L ferric chloride solution to etch the copper foil, and use a clean glass sheet t...

Embodiment 3

[0053] A kind of method of wet transfer graphene of the present embodiment, comprises the steps:

[0054] (1) Cut a piece of 20mm×20mm copper foil with graphene, and fix it on the surface of a square glass sheet with adhesive tape. The purpose is to ensure that the graphene film is flat. On the turntable, start the vacuum pump and homogenizer, set the low speed to 20rd / min, rotate for 6s, and the high speed to 2200rd / min, rotate for 40s, use a syringe to absorb PMMA with a mass fraction of 4%, use acetone as the solvent, and evenly drop it on the copper foil on the surface, then quickly put the lid on, start the spin coating, and form copper / graphene / PMMA;

[0055] (2) Remove the spin-coated PMMA copper foil and cure it for 100 minutes at a temperature of 135°C;

[0056] (3) Polish the side of the graphene copper foil that is not spin-coated with PMMA with fine sandpaper, put it into a 1mol / L ferric chloride solution to etch the copper foil, and use a clean glass piece to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com